Fully synthetic cutting fluid for metal processing and preparation method thereof

A metal processing, fully synthetic technology, applied in the field of lubricating oil, can solve the problems of easy spoilage of diluent, prolonged use time, insufficient lubrication, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

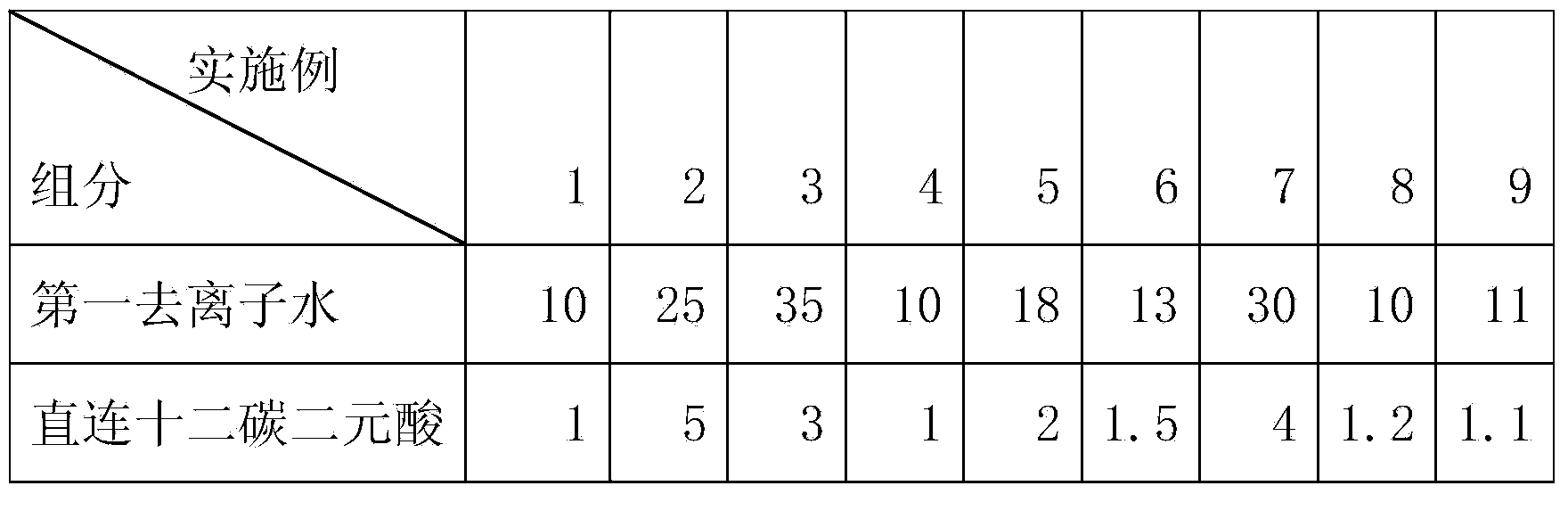

[0058] Embodiment: The raw material ratio of the fully synthetic cutting fluid for metal processing of the present invention embodiment 1-9 is detailed in the following table 1:

[0059] Table 1 (unit: percent by weight, %):

[0060]

[0061]

[0062] The above raw material indicators are as follows:

[0063] The first deionized water: pH: 5-8; Chloride ion: 0-100ppm; Conductivity: below 50us / cm;

[0064] Second deionized water: pH: 5-8; Chloride ion: 0-100ppm; Conductivity: below 50us / cm;

[0065] Boric acid: purity: over 99.9%; origin: intelligence;

[0066] Straight-chain dodecanedibasic acid: acid value: 418-468mgKOH / g;

[0067] Monoethanolamine: Purity: over 80%; pH (1%): 11.3±0.5;

[0068] Diethanolamine: content: above 80%, pH (1%): 10.5±0.5;

[0069] Fatty alcohol: molecular weight: 1100;

[0070] D1550 fatty acid: content: more than 80%, acid value: 268-288mgKOH / g;

[0071] Polyolefin: the number of carbon atoms is 16;

[0072] Defoamer: choose Dow Corning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com