Terpolymer and preparation method thereof, spacer material formed from the terpolymer, touch screen and preparation method thereof

A terpolymer, touch screen technology, applied in instruments, optics, nonlinear optics, etc., can solve problems such as poor pressing water ripples, pressing water ripples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

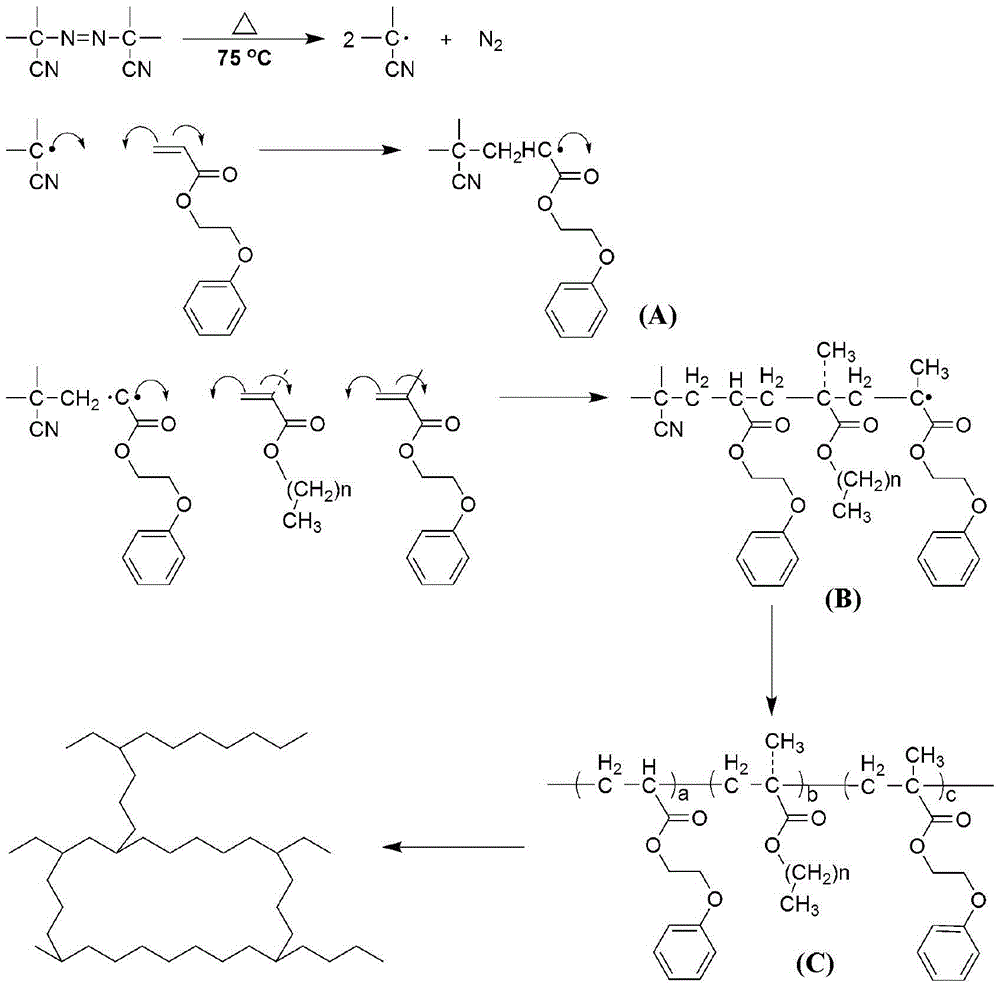

[0055] The embodiment of the present invention also provides a preparation method of the terpolymer provided in the above embodiment, comprising:

[0056] S1: Mix 2-phenoxyethyl acrylate, acrylate or methacrylate, 2-phenoxyethyl methacrylate, and a crosslinking agent uniformly in a molar ratio to prepare a reaction precursor.

[0057] In this step, the above compounds are weighed and mixed in an appropriate molar ratio, wherein the molar ratios are: 2-phenoxyethyl acrylate: 62.4-77.6%; methacrylate or acrylate: 15.6-19.4%; 2-phenoxyethyl methacrylate: 1-20%; cross-linking agent: 2.0%, the reaction precursor can only be obtained after mixing evenly.

[0058] S2: Adding an initiator to the reaction precursor, stirring evenly, blowing nitrogen gas, and heating at a constant temperature of 70-80° C. for 24 hours to obtain the terpolymer.

[0059] In this step, an initiator is added to the reaction precursor, and heated at a constant temperature of 70-80° C. for 24 hours to allow ...

Embodiment 1

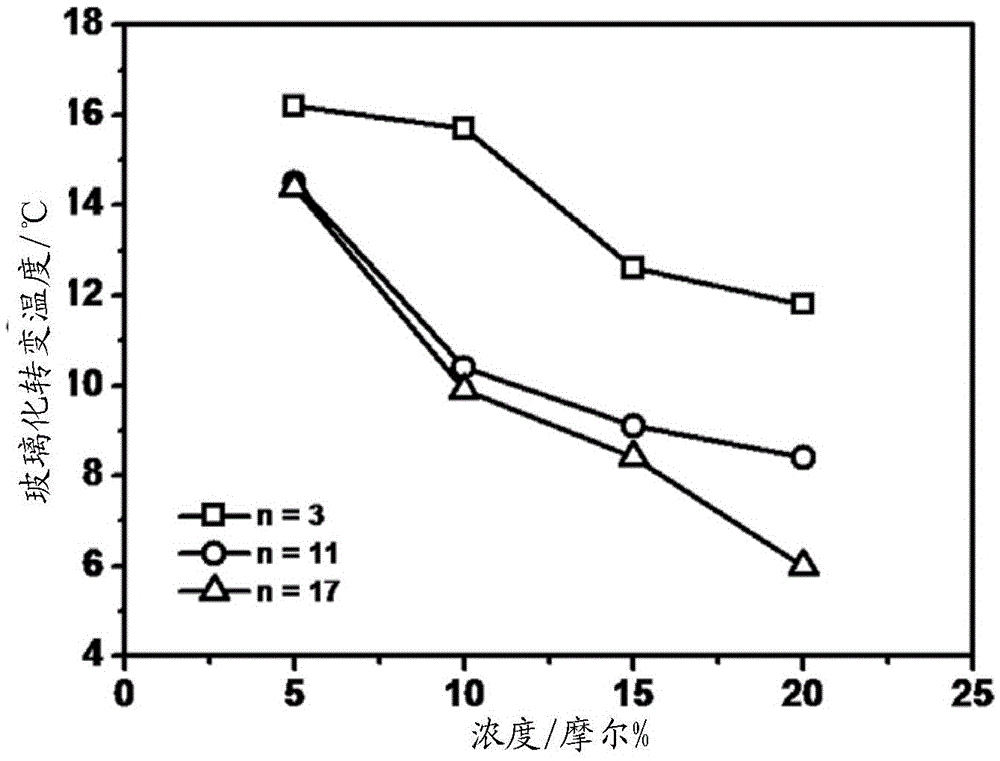

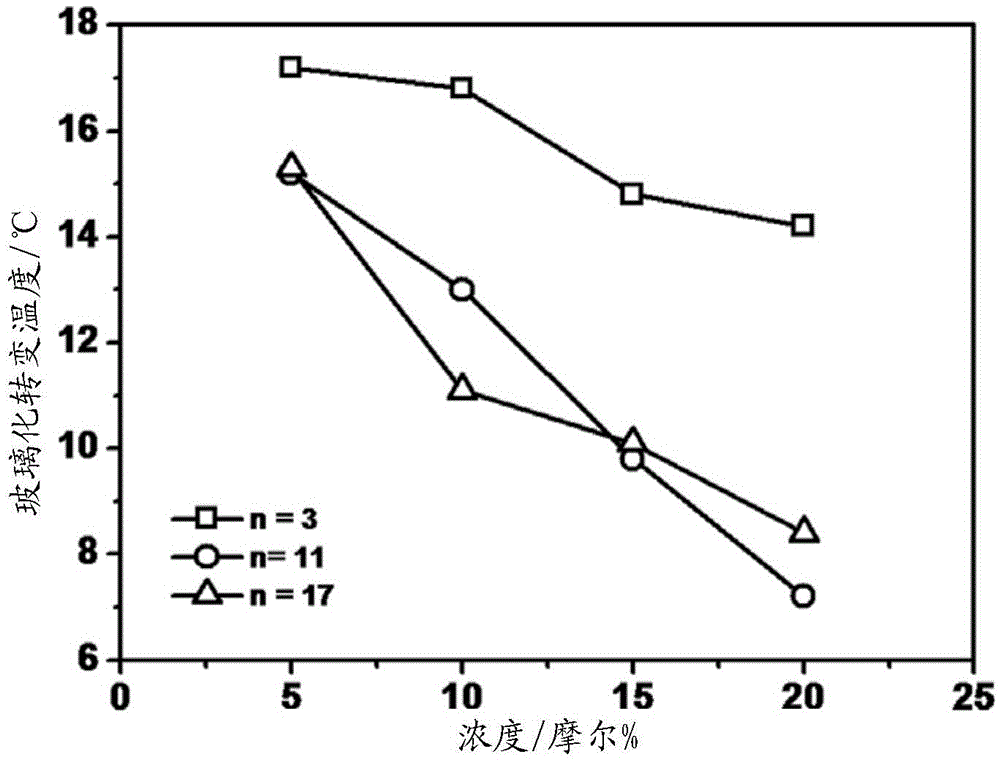

[0073] (a) The molar ratio of monomer 2-phenoxyethyl acrylate, 2-phenoxyethyl methacrylate, butyl acrylate, and crosslinking agent ethylene glycol dimethacrylate is 74.4mol%, 18.6 mol%, 5.0mol%, 2.0mol% mixed evenly;

[0074] (b) Add the initiator azobisisobutyronitrile with a mass ratio of 0.5% to the above mixture, stir and mix, and simultaneously feed nitrogen to remove the oxygen therein, and heat the reaction at a constant temperature of 70°C for 24 hours to obtain a ternary Copolymer, the Tg of this copolymer is 16.2°C;

[0075] (c) using the terpolymer prepared in step (b) to make a spacer on the color filter substrate;

[0076] (d) combining the array substrate dripped with liquid crystal and the color filter substrate coated with the sealant mixture, performing ultraviolet polymerization and thermal polymerization, and then cooling to room temperature to produce a liquid crystal panel;

[0077] (e) coating a photoresist on the touch panel, and fixing it on the liqui...

Embodiment 2

[0081] (a) the monomer 2-phenoxyethyl acrylate, 2-phenoxyethyl methacrylate, lauryl acrylate, crosslinking agent ethylene glycol dimethacrylate in a molar ratio of 70.4mol%, 17.6mol%, 10.0mol%, 2.0mol% are mixed evenly;

[0082] (b) Add the initiator azobisisobutyronitrile with a mass ratio of 0.5% to the above mixture, stir and mix, and simultaneously feed nitrogen to remove the oxygen therein, and heat the reaction at a constant temperature of 75°C for 24 hours to obtain a ternary Copolymer, the Tg of this copolymer is 10.4°C;

[0083] (c) using the terpolymer prepared in step (b) to make a spacer on the color filter substrate;

[0084] (d) combining the array substrate dripped with liquid crystal and the color filter substrate coated with the sealant mixture, performing ultraviolet polymerization and thermal polymerization, and then cooling to room temperature to produce a liquid crystal panel;

[0085] (e) coating a photoresist on the touch panel, and fixing it on the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com