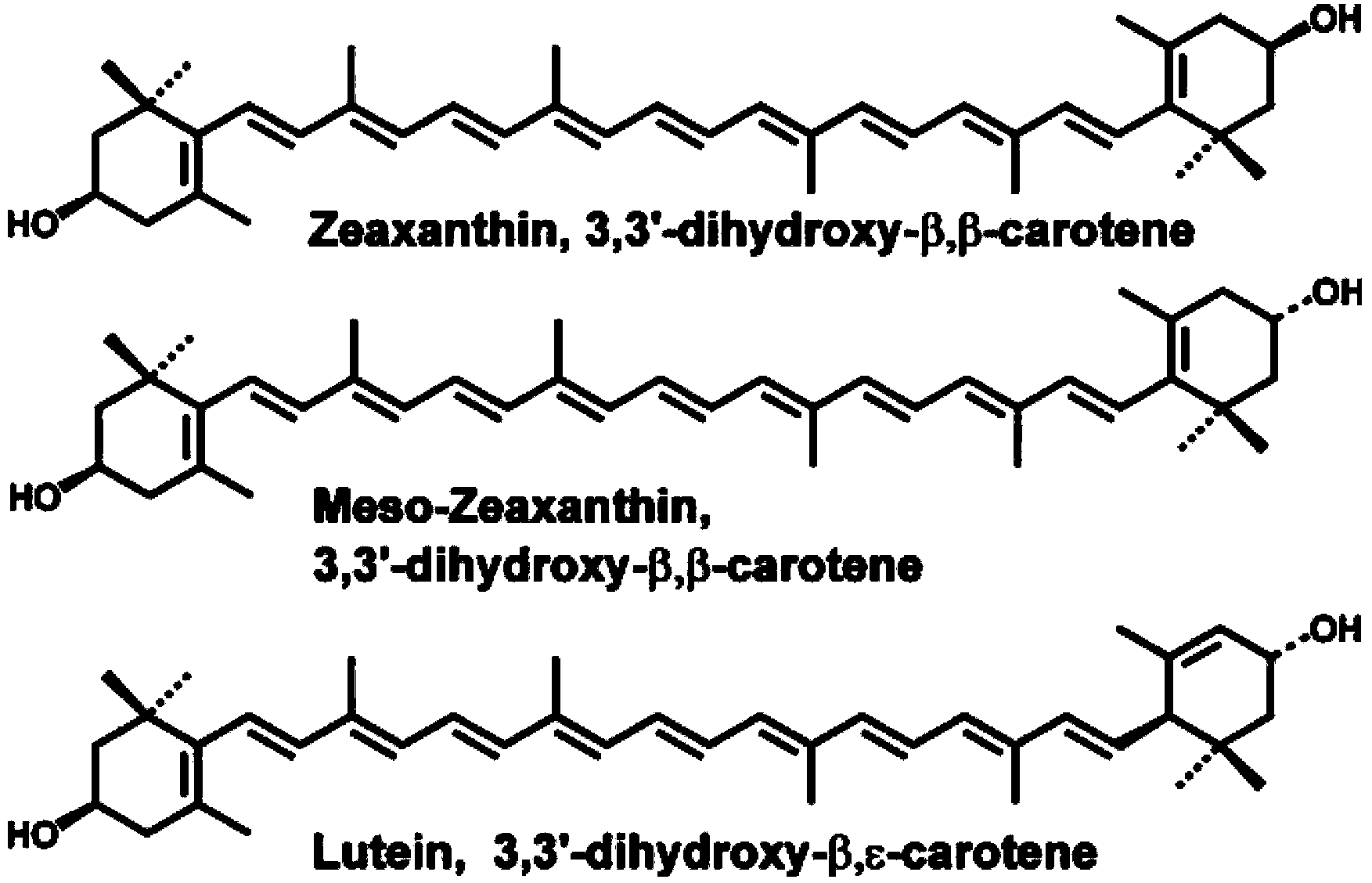

Method for preparing natural zeaxanthine by combination of enzymatic hydrolysis and supercritical extraction

A zeaxanthin, supercritical technology, applied in the direction of organic chemistry, fermentation, etc., can solve the problems of large amount of solvent, low extraction efficiency, inability to realize industrialization, etc., and achieves high extraction efficiency, alleviation of eye fatigue, and good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The natural zeaxanthin was prepared according to the following process with the fruit of Jindenglong as raw material:

[0029] Take 1000 grams of fresh brocade lantern fruit, wash and beat, add 1 liter of deionized water and mix well, then add 10 grams of mixed enzymes, mixed enzymes pectinase 2.5 grams, cellulase 2.5 grams, lipase 5 grams; use 1M The pH was adjusted to 7 with NaOH, and the enzymolysis was stirred at 30°C for 10 hours; after the enzymolysis was completed, it was freeze-dried to obtain the enzymolyzate.

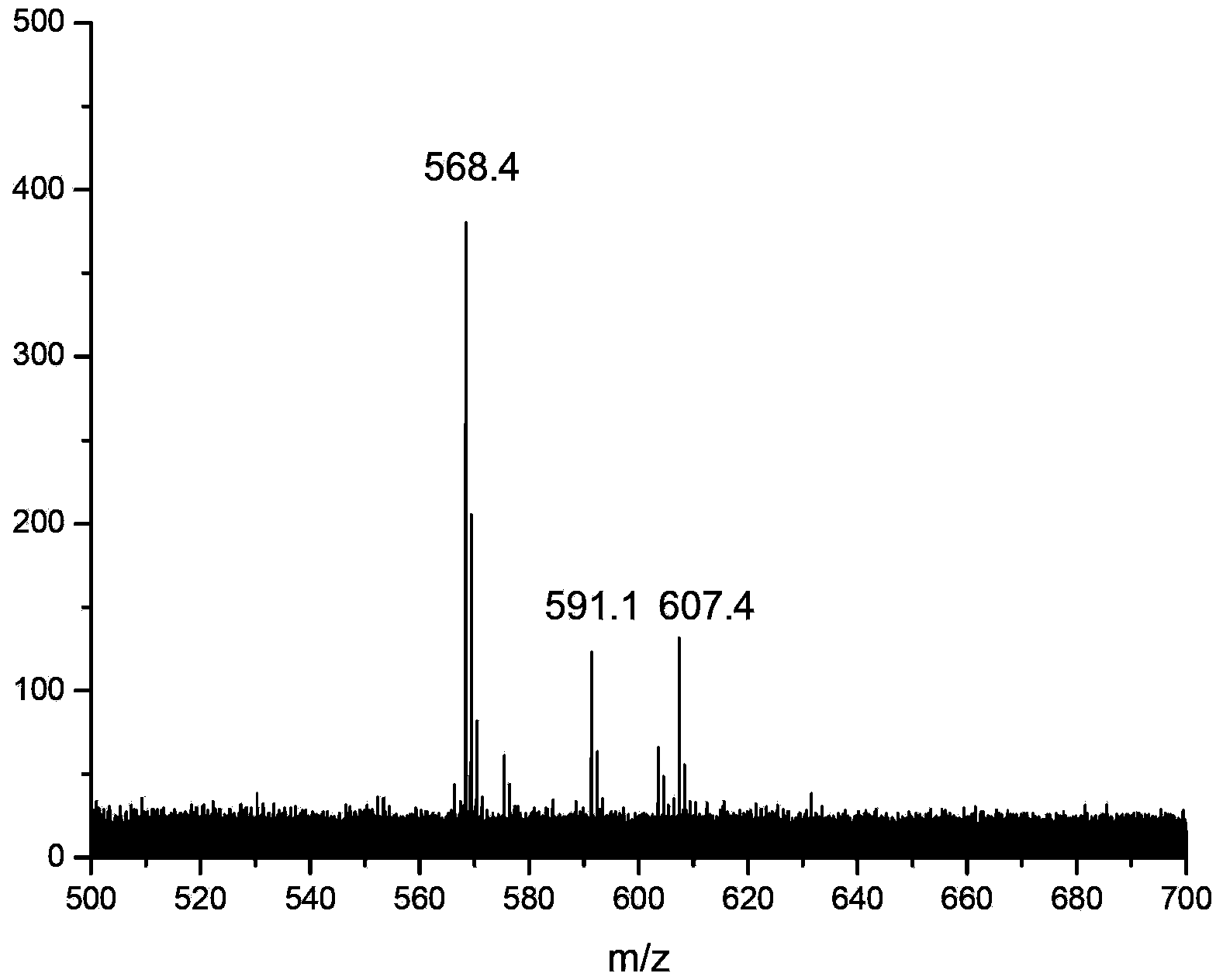

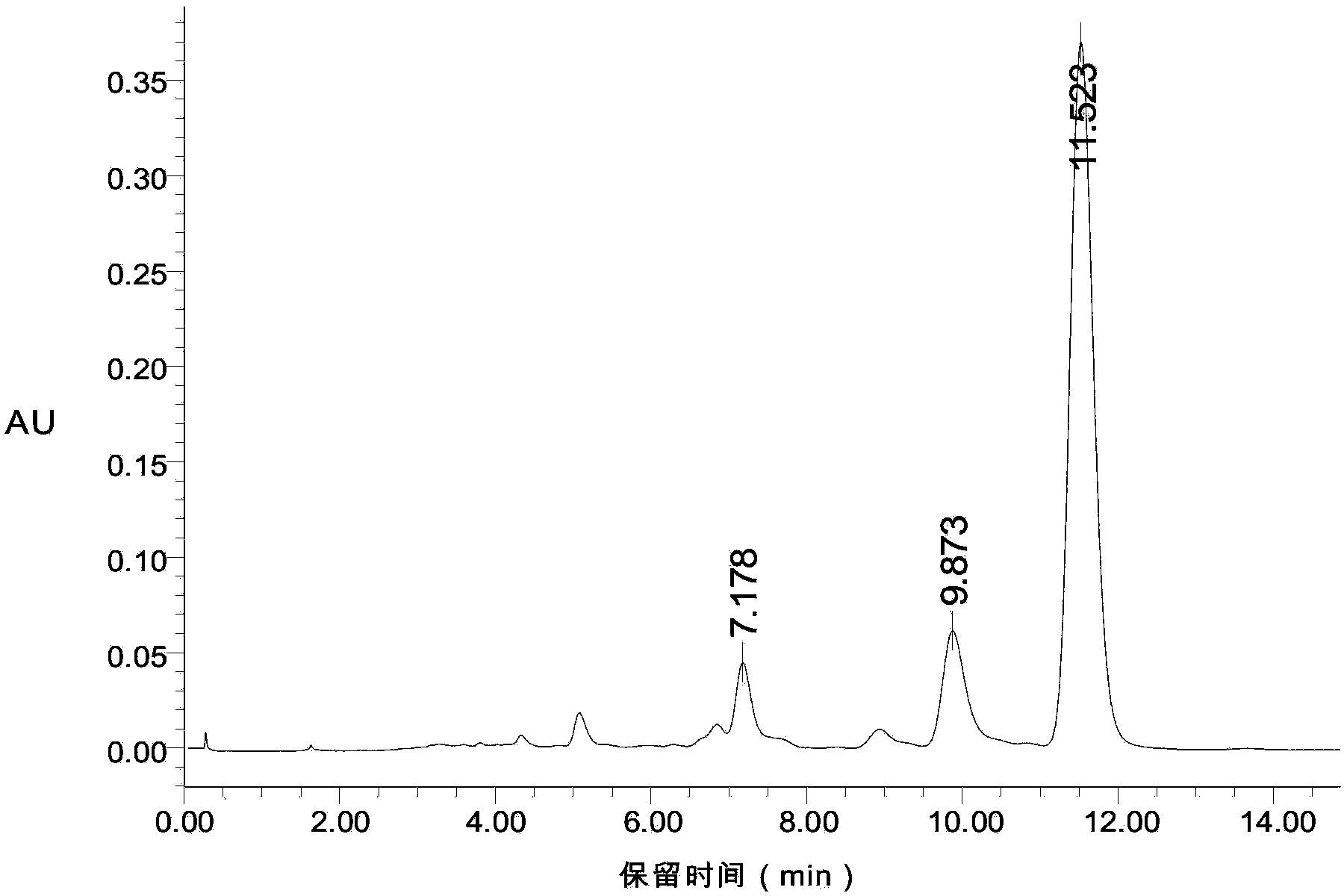

[0030] Crush the freeze-dried enzymatic hydrolyzate through a 100-mesh sieve, take the sieved enzymatic hydrolyzate and add it to the supercritical extraction kettle, and add 100 ml of absolute ethanol as an entrainer at the same time, close the extraction kettle and fill it with carbon dioxide gas to a pressure of 20MPa , the temperature was raised to 60° C., and the extraction was started. Open the sampling valve every half hour to take out the extra...

Embodiment 2

[0033] Using Lycium barbarum as raw material, natural zeaxanthin was prepared according to the following process:

[0034] Take 1000 grams of fresh Lycium barbarum, wash and beat, add 10 liters of deionized water and mix well, then add 50 grams of mixed enzymes, mixed enzymes pectinase 5 grams, cellulase 20 grams, lipase 35 grams; use 1M The pH was adjusted to 5 with HCI, and the enzymolysis was stirred at 50°C for 1 hour; after the enzymolysis was completed, it was freeze-dried to obtain the enzymolyzate.

[0035] Crush the freeze-dried enzymatic hydrolyzate through a 200-mesh sieve, take the sieved enzymatic hydrolyzate and add it to the supercritical extraction kettle, add 800 ml of entrainer ethyl acetate at the same time, close the extraction kettle and fill it with carbon dioxide gas to a pressure of 50MPa , the temperature was raised to 40° C., and the extraction was started. Open the sampling valve every half hour to take out the extract, add the same amount of entrai...

Embodiment 3

[0039] Using capsicum as raw material, natural zeaxanthin was prepared according to the following process:

[0040] Take 1000 grams of fresh peppers, wash them, beat them, add 8 liters of deionized water and mix well, then add 100 grams of mixed enzymes, 20 grams of mixed enzymes pectinase, 40 grams of cellulase, and 40 grams of lipase; use 1M NaOH The pH was adjusted to 8, and the enzymatic hydrolysis was stirred at 70°C for 1 hour; after the enzymatic hydrolysis was completed, it was freeze-dried to obtain the enzymatic hydrolyzate.

[0041] The freeze-dried enzymatic hydrolyzate was crushed through a 100-mesh sieve, and the sieved enzymatic hydrolyzate was added to a supercritical extraction kettle. At the same time, 400 ml of petroleum ether was added as an entrainer, and the extraction kettle was closed and filled with carbon dioxide gas to a pressure of 60MPa. The temperature was raised to 30° C., and the extraction was started. Open the sampling valve every half hour t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com