Microcrystal mirror polishing wall tile and manufacturing method thereof

A technology of mirror polishing and manufacturing methods, which is applied in the field of ceramic glazed tiles, can solve the problems of prone to collapse, low sintering temperature, color development, porous glazed surface, etc., and achieve firm and reliable bonding, improved thermal stability, and improved moisture retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

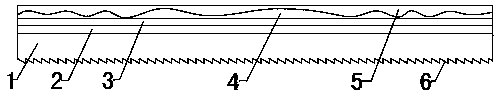

Image

Examples

Embodiment 1

[0028] 1) The clay raw materials are prepared by weight: 38 parts of limestone, 28 parts of Laiyang soil, 14 parts of burnt gemstone, 9 parts of green clay, 2 parts of talc, 2 parts of magnetite, and 7 parts of black mud. After ball milling, powder milling and aging, the bisque is pressed and formed, and the pressed biscuit is fired once. The firing temperature of the primary firing is controlled at 1080 ° C, and the sintering time is 45 minutes. The expansion coefficient is 205, and the ceramic adobe bottom brick made by one-time firing is sprayed with water, and the amount of water sprayed is 20 grams per 0.18 square meters;

[0029] 2) The base glaze is firstly applied on the ceramic base brick after water spraying, and the base glaze is firstly prepared according to weight: 100 parts of glaze, 0.06 part of cellulose, and 0.4 part of sodium tripolyphosphate. The bottom glaze is applied with a thickness of 0.25mm, and the top glaze is applied on top of the bottom glaze. The ...

Embodiment 2

[0033] 1) The clay raw materials are prepared by weight: 39 parts of limestone, 27 parts of Laiyang soil, 15 parts of burnt gemstone, 8 parts of green clay, 2.2 parts of talc, 1.8 parts of magnetite, and 7.5 parts of black mud. After ball milling, powder milling and aging, the bisque is pressed and formed, and the pressed biscuit is fired once. The firing temperature of the primary firing is controlled at 1090 ° C, and the sintering time is 44 minutes. The expansion coefficient is 207, and the ceramic adobe bottom brick made by one-time firing is sprayed with water, and the amount of water sprayed is 21 grams per 0.18 square meters;

[0034] 2) The bottom glaze is firstly applied on the pottery base brick after water spraying, and the bottom glaze is firstly prepared according to weight: 100 parts of glaze, 0.05 part of cellulose, and 0.3 part of sodium tripolyphosphate. The bottom glaze is applied with a thickness of 0.3mm, and the top glaze is applied on top of the bottom gl...

Embodiment 3

[0038] 1) The clay raw materials are prepared by weight: 37 parts of limestone, 29 parts of Laiyang soil, 13 parts of burnt gemstone, 10 parts of green clay, 2.2 parts of talc, 1.6 parts of magnetite, and 6.5 parts of black mud. After ball milling, powder milling and aging, the green body is pressed and formed, and the pressed green body is fired once. The firing temperature of the first firing is controlled at 1070 ° C, and the sintering time is 46 minutes. The expansion coefficient is 208, and the ceramic adobe bottom brick made by one-time firing is sprayed with water, and the water spray volume is 22 grams per 0.18 square meters;

[0039] 2) The base glaze is firstly applied on the pottery base brick after water spraying, and the base glaze is firstly prepared according to weight: 100 parts of glaze, 0.07 part of cellulose, and 0.4 part of sodium tripolyphosphate. The bottom glaze is applied with a thickness of 0.3mm, and the top glaze is applied on the bottom glaze. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com