Carbon disulfide reaction furnace of novel material

A technology of carbon disulfide and new materials, which is applied in the field of carbon disulfide reaction furnaces, can solve the problems of not being able to meet the long life of the furnace body, gradually corrode materials, and useless practical applications, so as to avoid sulfidation and oxidation reactions, good thermal shock stability, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

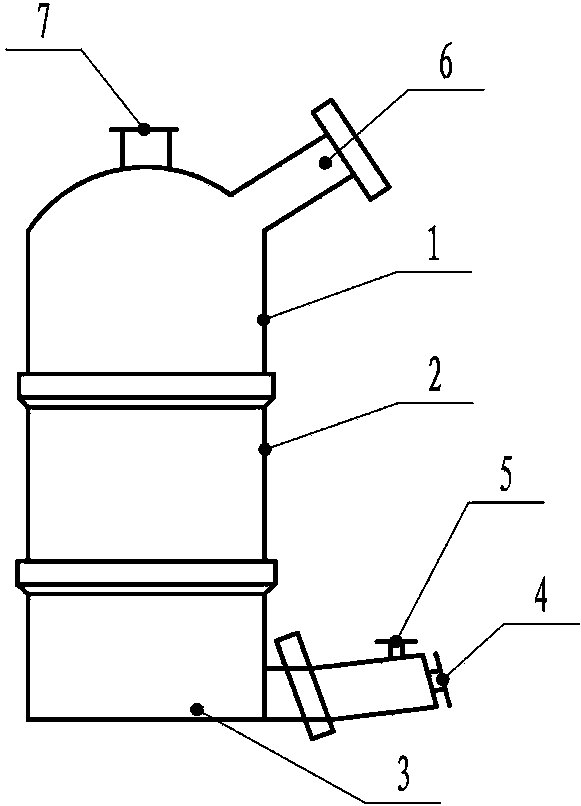

[0016] A carbon disulfide reaction furnace of a new type of material, including a furnace body. The furnace body is divided into an upper part of the furnace body, a middle part of the furnace body and a lower part of the furnace body. and the sulfur addition port, the furnace body is made of refractory material silicon nitride combined with silicon carbide, the upper part of the furnace body and the middle part of the furnace body, and the middle part of the furnace body and the lower part of the furnace body are bonded with refractory mud. A cover made of metal or high-temperature ceramics is arranged at the slag port and the carbon feeding port.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com