Graphene tube-wrapped metal nitride nanobelt and preparation method thereof

A technology of graphene tubes and nanobelts, which is applied in the direction of graphene, nitrogen-metal/silicon/boron binary compounds, nano-carbon, etc., can solve the problems of capacity loss and poor dynamic performance, and achieve lower resistivity and better Electrochemical properties, the effect of facilitating the transport of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of a graphene nanotube wrapped molybdenum nitride nanoribbon comprises the following steps:

[0033] 1) Weigh 20 mg of dried molybdenum trioxide, stir and ultrasonically disperse in distilled water, then add 1 mL of polydiallyl dimethyl ammonium chloride solution, continue to stir for 5 minutes and then centrifuge, measure 5 mL of 1 mg / mL prepared by Hummer method Graphene oxide dispersion liquid, add the concentrated molybdenum oxide liquid obtained by centrifugation into the graphene oxide dispersion liquid drop by drop, ultrasonically disperse and stir until the dispersion is even, then suction filter and dry;

[0034] 2) Remove the dried membrane from the filter membrane, and perform annealing treatment in an ammonia atmosphere at a heating rate of 1-10°C / min, an annealing temperature of 400-1200°C, and a holding time of 60-120min to obtain A graphene nanotube wrapped molybdenum nitride nanoribbon.

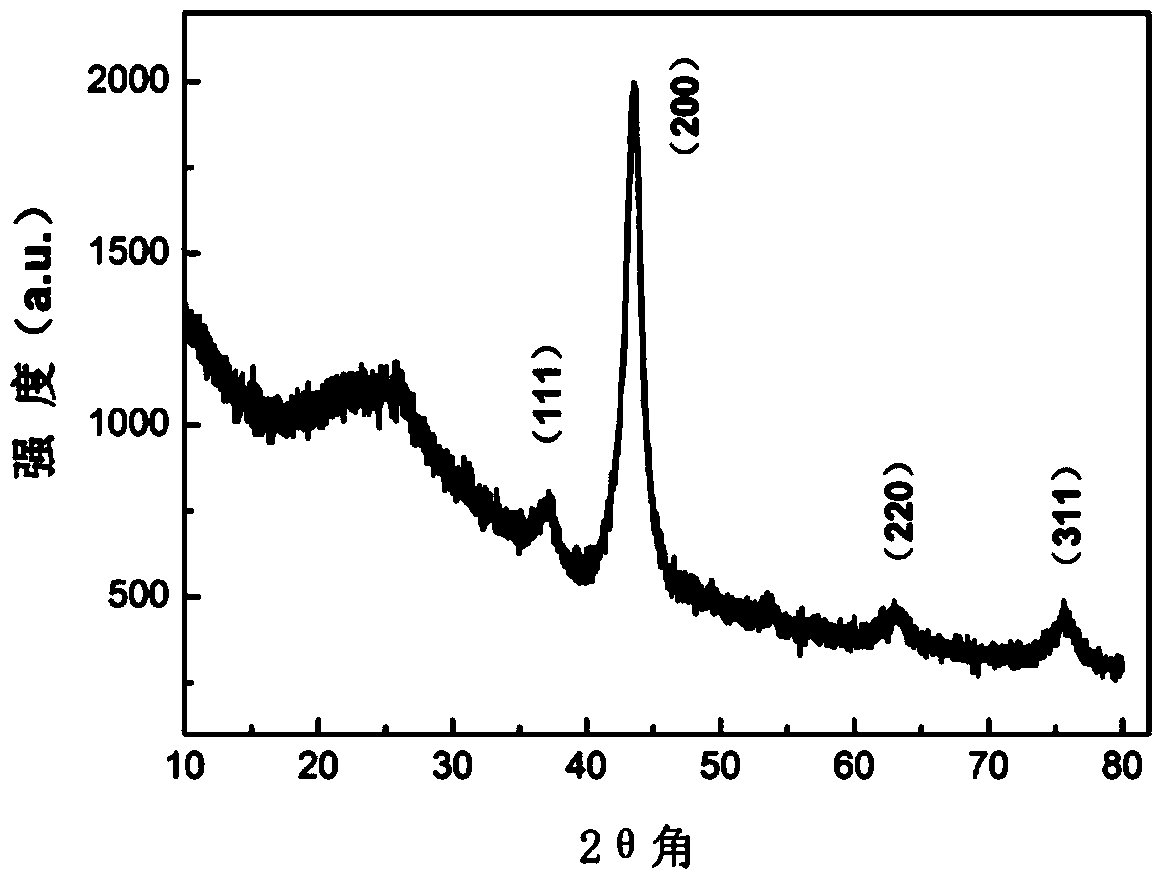

[0035] Such as figure 1 As shown, XRD proves tha...

Embodiment 2

[0040] The preparation of a graphene nanotube wrapped molybdenum nitride nanoribbon comprises the following steps:

[0041] 1) Weigh 100 mg of dried molybdenum trioxide, stir and ultrasonically disperse in distilled water, then add 15 mL of polydiallyl dimethyl ammonium chloride solution, continue stirring for 30 min and then centrifuge, measure 50 mL of 1 mg / mL prepared by Hummer method Graphene oxide dispersion liquid, add the concentrated molybdenum oxide liquid obtained by centrifugation into the graphene oxide dispersion liquid drop by drop, ultrasonically disperse and stir until the dispersion is even, then suction filter and dry;

[0042] 2) Remove the dried membrane from the filter membrane, and perform annealing treatment at an ammonia atmosphere at a heating rate of 1-10°C / min, an annealing temperature of 400-1200°C, and a holding time of 10-60min to obtain A graphene nanotube wrapped molybdenum nitride nanoribbon.

Embodiment 3

[0044] The preparation of a graphene nanotube wrapped molybdenum nitride nanoribbon comprises the following steps:

[0045] 1) Weigh 200mg of dried molybdenum trioxide, stir and ultrasonically disperse in distilled water, then add 30mL of polydiallyldimethylammonium chloride solution, continue stirring for 60min and then centrifuge, measure 100mL of 1mg / mL prepared by Hummer method Graphene oxide dispersion liquid, add the concentrated molybdenum oxide liquid obtained by centrifugation into the graphene oxide dispersion liquid drop by drop, ultrasonically disperse and stir until the dispersion is even, then suction filter and dry;

[0046] 2) Remove the dried membrane from the filter membrane, and perform annealing treatment in an ammonia atmosphere at a heating rate of 10-20°C / min, an annealing temperature of 400-1200°C, and a holding time of 10-120min to obtain A graphene nanotube wrapped molybdenum nitride nanoribbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com