Surface texture of indium-iron composite spherical microcrystal composite layer

A surface texture, composite ball technology, applied in layered products, metal layered products, chemical instruments and methods, etc., to achieve good self-lubricating properties, reduce friction and wear, and improve composite fretting wear effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

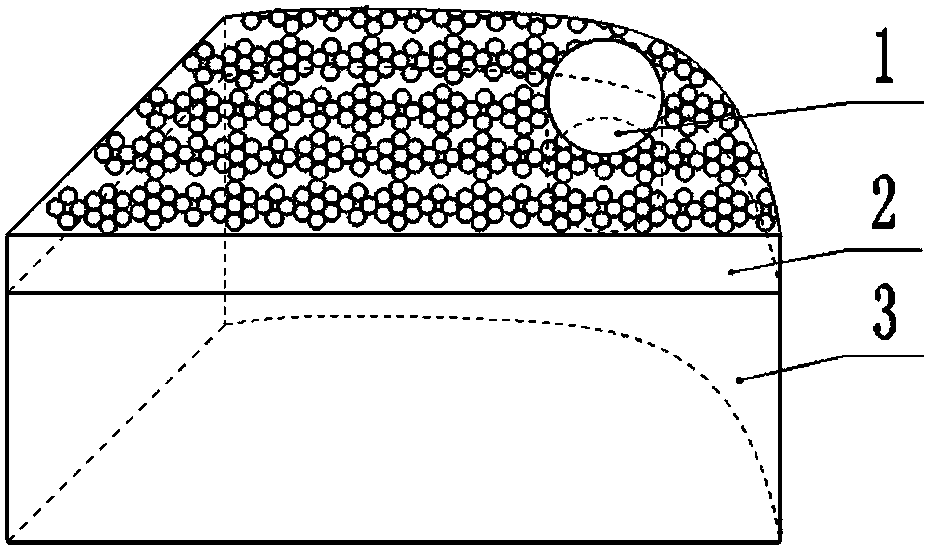

[0024] figure 1 It is a schematic structural view of the surface texture of the indium-iron composite ball microcrystalline composite layer in Example 1 of the present invention, figure 2 It is a 20,000-fold scanning electron microscope image of the part surface material layer of the indium-iron composite ball microcrystalline composite layer surface texture in Example 1 of the present invention, image 3 It is the 10,000 times scanning electron microscope image of the part surface material layer of the indium-iron composite ball microcrystalline composite layer surface texture of embodiment 1 of the present invention, Fig. 4 ( Pic 4-1 and Figure 4-2 ) is the embodiment 1 of the present invention image 3 The energy spectrum of an indium-iron composite spherical crystallite unit in . In the accompanying drawings, 1 is a circular surface texture unit, 2 is a surface material layer of a part, and 3 is a matrix material.

[0025] The surface texture of the indium-iron comp...

Embodiment 2

[0028] figure 1 It is a schematic structural view of the surface texture of the indium-iron composite ball microcrystalline composite layer in Example 1 of the present invention, figure 2 It is a 20,000-fold scanning electron microscope image of the part surface material layer of the indium-iron composite ball microcrystalline composite layer surface texture in Example 1 of the present invention, image 3 It is the 10,000 times scanning electron microscope image of the part surface material layer of the indium-iron composite ball microcrystalline composite layer surface texture of embodiment 1 of the present invention, Fig. 4 ( Pic 4-1 and Figure 4-2 ) is the embodiment 1 of the present invention image 3 The energy spectrum of an indium-iron composite spherical microcrystalline unit in , Figure 5 It is a schematic structural diagram of the surface texture of the indium-iron composite ball microcrystalline composite layer in Example 2 of the present invention. In the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com