Novel measurement method for dynamic characteristic of tool nose of micro-diameter milling tool

A technology of dynamic characteristics and measurement methods, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of incomplete milling processing conditions, simple measurement results of models, and difficult determination of boundary conditions, etc., to achieve measurement The method is simple and easy to implement, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

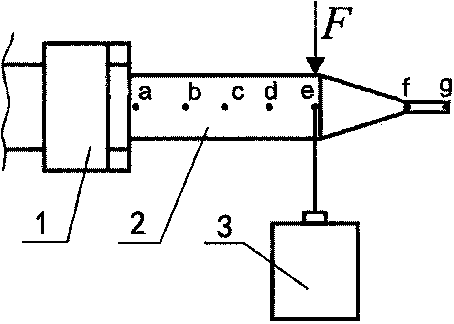

[0018] Such as figure 1 As shown, the present invention is a method for measuring the dynamic characteristics of the tip of the micro-diameter milling cutter.

[0019] 1. Clamp the micro-diameter milling cutter with a cutting diameter of 0.5mm (length 3mm) and a handle diameter of 3mm (length 25mm) in the tool holder of the milling machine spindle.

[0020] 2. Use a micro-pulse hammer (PCB 30722, sensitivity 23.76 mV / N) to apply an exciting force F to the micro-diameter milling cutter at point e of the handle.

[0021] 3. Use a scanning laser vibrometer (POLYTEC PSV-400-M2) to measure the vibration displacement of each measurement point (a, b, c, d, e, f, g) on the milling cutter.

[0022] 4. Use the signal processing software (LMS Test.Lab) to conduct modal synthesis on the vibration response to obtain the dynamic characteristics of the micro-diameter milling cutter tip.

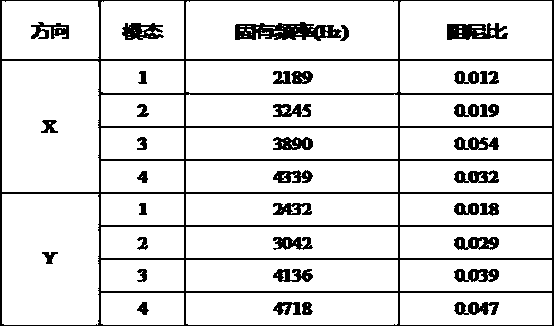

[0023] 5. The measured dynamic characteristics of the tip of the micro-diameter milling cutter in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com