Discrete combination type arm frame for super-large centrifugal machine

A centrifuge and discretization technology, applied in the field of centrifuge boom, can solve the problems of increased development cost, increased cost, large radial area, etc., and achieves the effects of decentralized processing and transportation, reduced development cost, and reduced load waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the drawings:

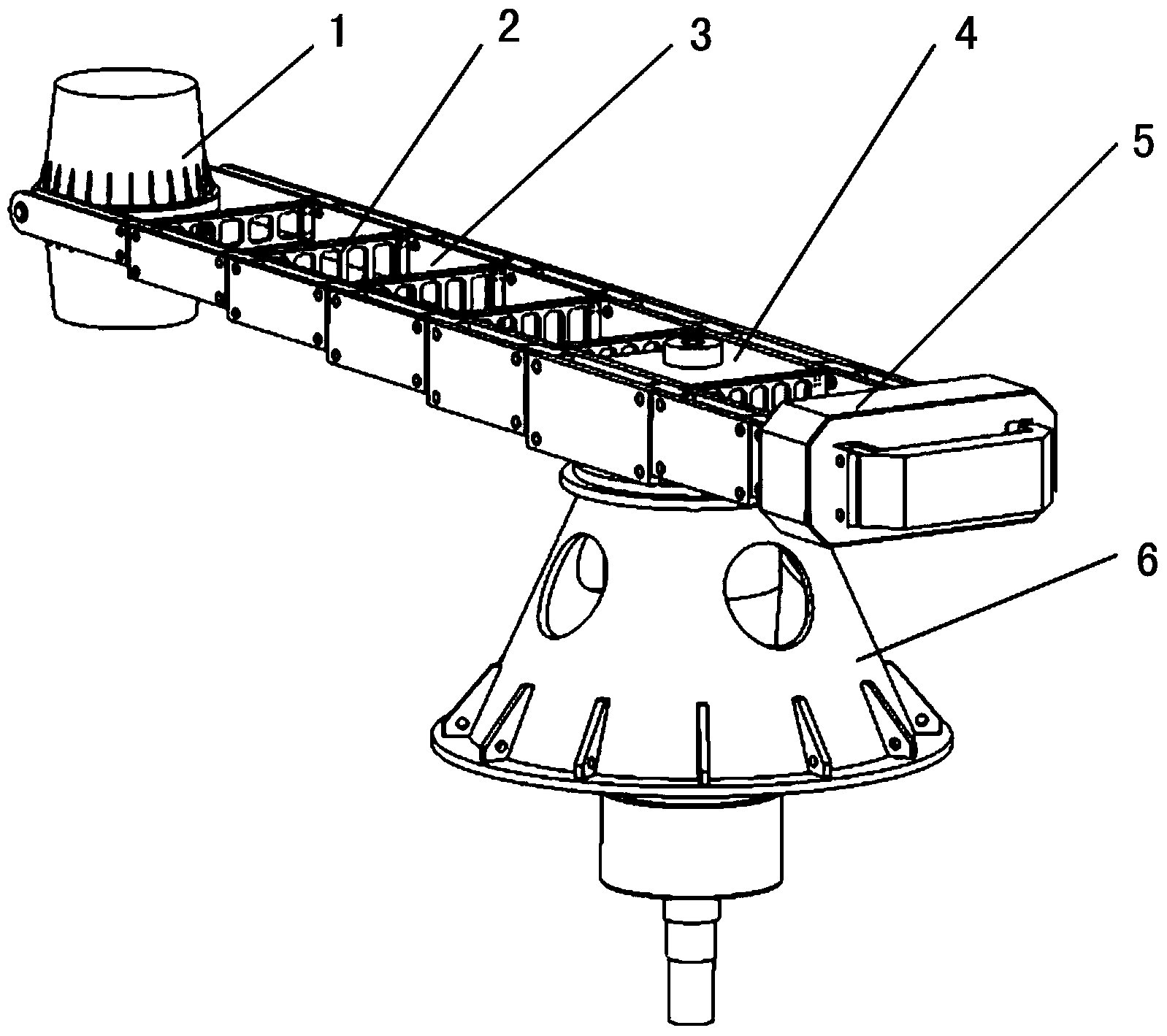

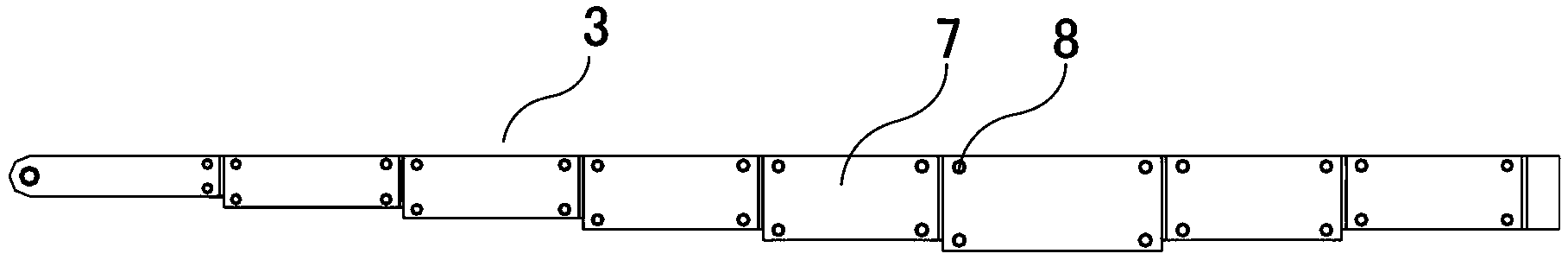

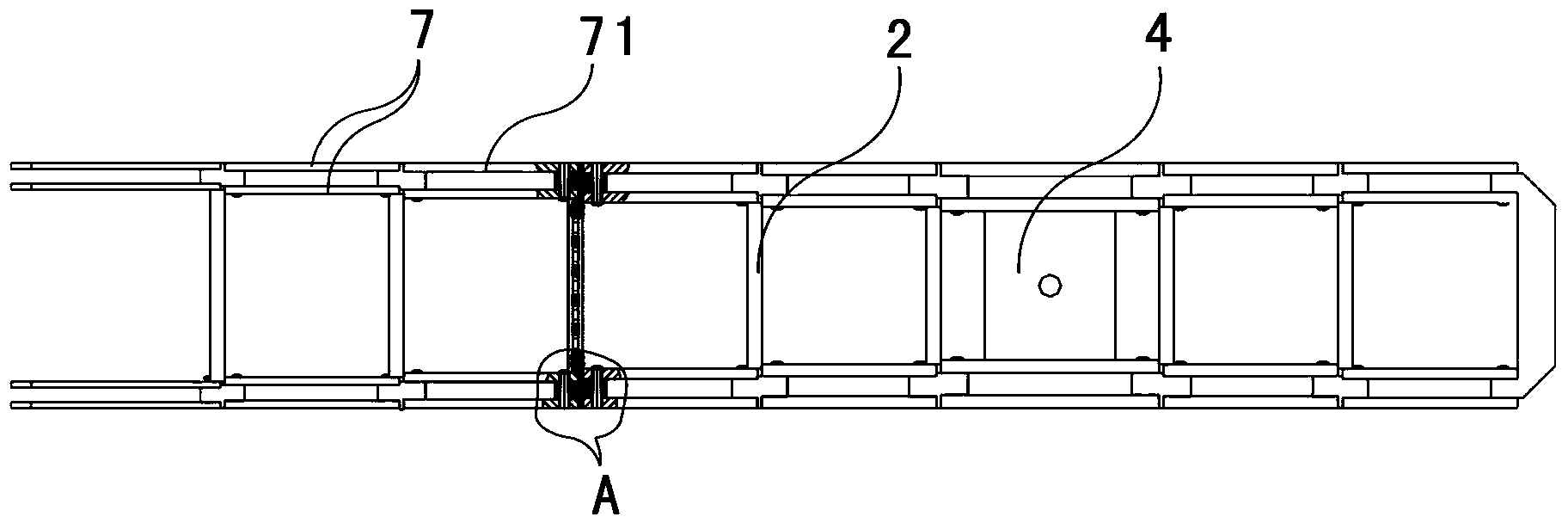

[0023] Such as figure 1 As shown, the discrete combined boom of the ultra-large centrifuge of the present invention includes two tension belts 3 and a plurality of parallel and spaced connecting plates 2 connected between the two tension belts 3. A rotating arm support plate 4 is installed in the middle section. The rotating arm support plate 4 is used to connect the boom and the main shaft (not marked in the figure); in order to facilitate the overall understanding of the centrifuge, figure 1 The bell 6 for supporting the boom, the hanging basket 1 and the counterweight 5 for balancing are also shown in the boom. The main shaft drives the boom through the rotating arm support plate 4, and the boom drives the gondola 1 and the counterweight 5 to rotate. The gondola 1 is equipped with experimental specimens, and various centrifugal experimental data are collected during the rotation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com