High-brightness electric baking pan heating plate and manufacturing method thereof

A heating plate, electric baking pan technology, applied in household appliances, frying pans, applications, etc., can solve the problems of difficult cleaning, uneven surface of the heating plate, uneven heat conduction, etc., to achieve non-stick cleaning, non-cracking shape, shape beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

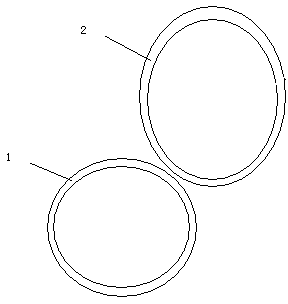

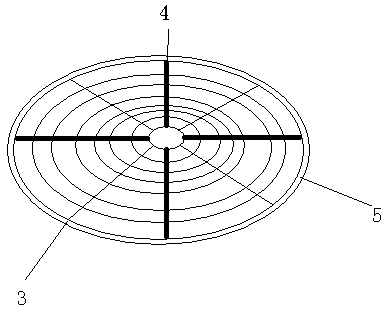

[0025] like figure 1 , 2 As shown in the figure, the heating plate of the high-brightness electric baking pan has a mirror structure (bright surface) on the heating surface, and air grooves 3 and telescopic ribs 4 are provided on the back of the heating plate. The air grooves 3 are radially distributed around the center of the heating disc. The expansion ribs 4 are radially distributed around the center of the heating plate. The air grooves 3 and the telescopic ribs 4 are arranged at intervals.

[0026] An extension ring 5 is provided on the outer circumference of the high-brightness electric baking pan heating plate.

[0027] A method for processing a heating plate of a high-brightness electric baking pan, comprising the following steps:

[0028] (1) Melting the aluminum ingot at high temperature, the melting temperature is 660-680°C, and the melting time is 1-2h;

[0029] (2) The smelted aluminum is cleaned of sand;

[0030] (3) The smelted aluminum that has been sand-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com