Shock-resistant latch mechanism

A latch and shock-resistant technology, which is applied in building locks, connecting components, mechanical equipment, etc., can solve problems such as the inability to install vibration-resistant latches, and achieve the effects of lowering the center of gravity, compact shock-resistant latch mechanism, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described with reference to the drawings.

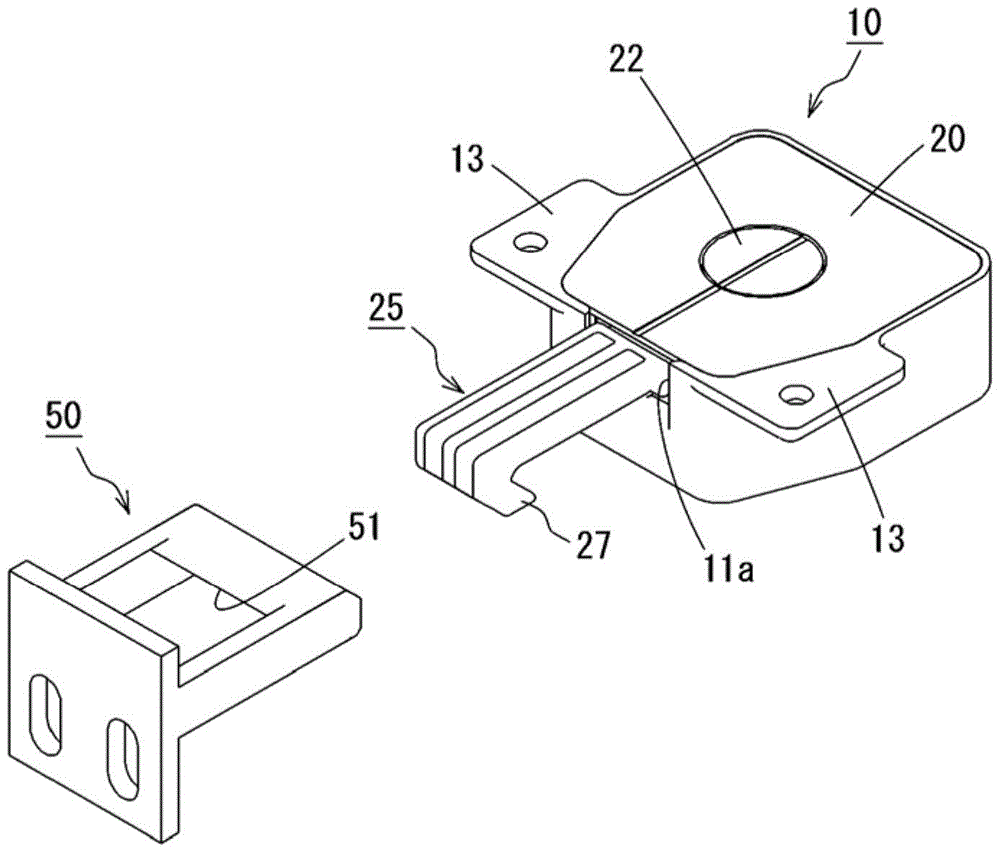

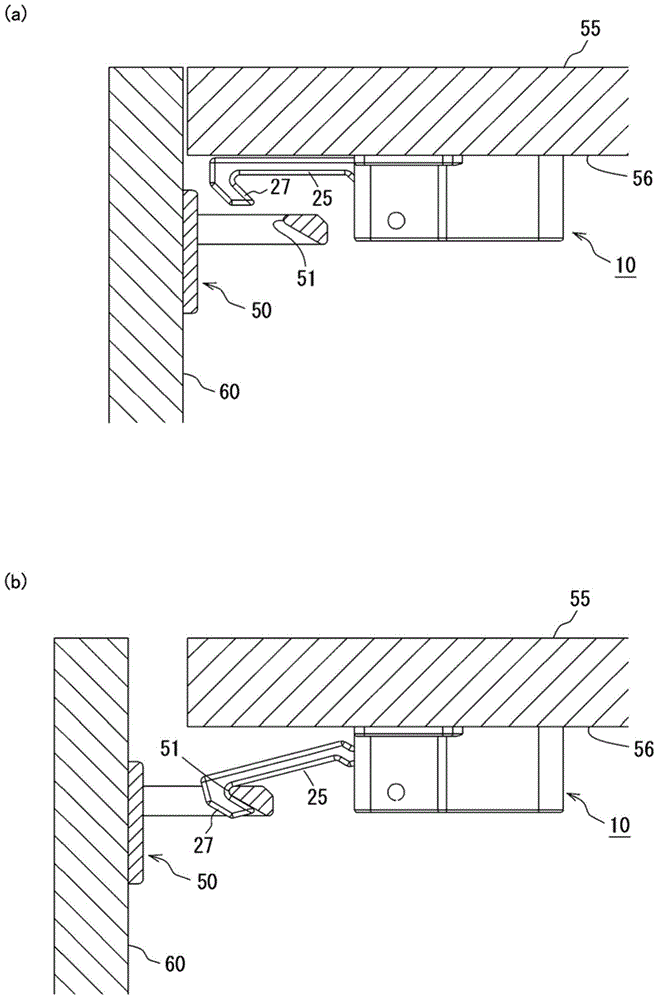

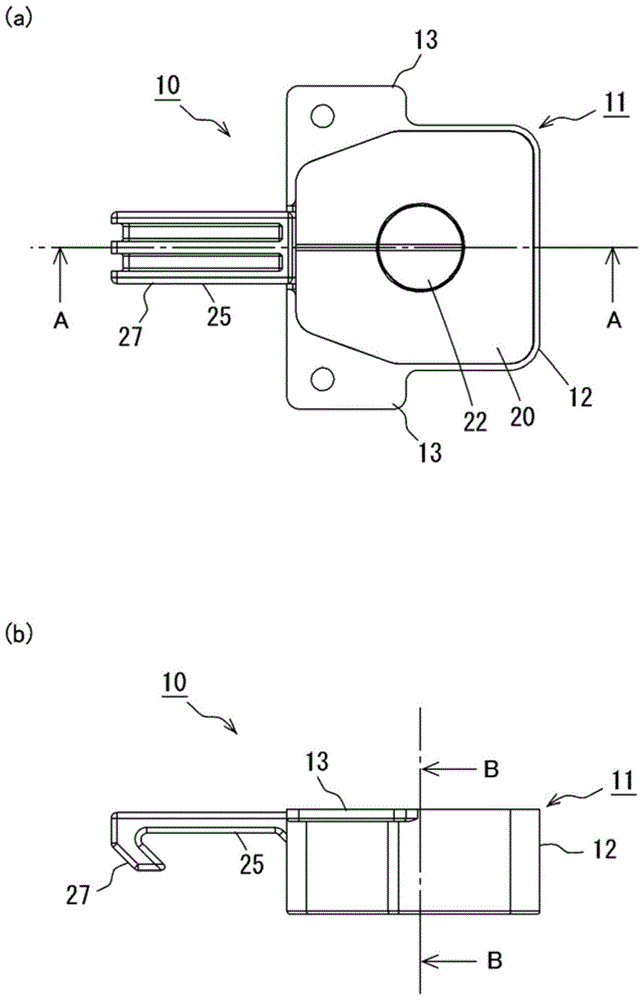

[0042] Such as figure 1 As shown, the shockproof latch mechanism 10 of this embodiment is used to engage with the receiving portion 50 to lock the door body 60 so that the door body 60 does not open. For example, if figure 2 As shown, the receiving portion 50 is fixed on the inner side of the door body 60, and the anti-shock latch mechanism 10 is fixed on the top surface of the top plate portion 56 of the frame body 55, so that the receiving portion 50 and the anti-shock latch mechanism 10 are arranged oppositely. A hook 27 protrudes from the opening 11a of the housing 11 of the shockproof latch mechanism 10, and when the hook 27 swings in the closed state of the door body 60, the hook 27 is arranged to engage with the hook engaging portion 51 of the receiving portion 50. . When vibration such as an earthquake occurs in this state, the internal mechanism of the shock-resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com