Fuel nozzle

A technology of fuel nozzles and fuel oil, which is applied in the direction of fuel injection devices, engine components, machines/engines, etc. It can solve the problems of affecting the engine power index, the effect of preheating is not obvious, and the heat loss is large, so as to protect the normal operation and weight. Effect of lightness, combustion efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

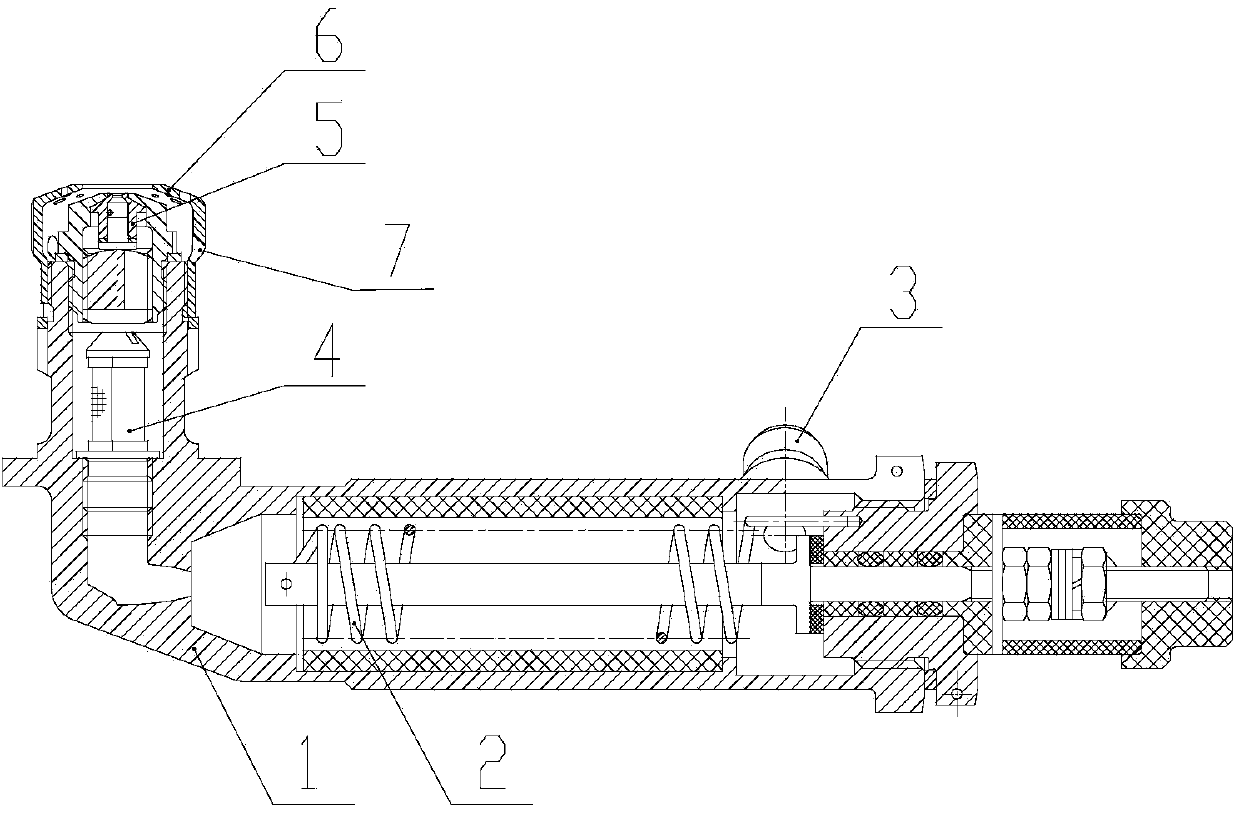

[0007] As shown in the figure, the fuel nozzle includes a housing 1, a fuel preheating device, an oil filter 4 and a fuel injection device 5. The fuel preheating device, oil filter 4 and fuel injection device 5 are sequentially installed on the housing, and the fuel The preheating device includes an oil supply joint 3 and a resistance wire 2. The oil supply joint 3 is located on the casing 1, and an oil circuit is arranged inside and communicated with the interior of the casing 1. The resistance wire 2 is located inside the casing 1, and one end of the resistance wire 2 is located at the supply The oil joint 3 is at the position, and the other end is set at the position where the oil filter 4 is installed; the fuel injection device 5 is set at the end of the housing, and the fuel directly enters the fuel injection device 5 after passing through the oil filter 4 . The fuel injection device 5 is provided with an outer casing nut 6 , and the outer casing nut 6 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com