Plane and facade construction method for APF self-adhibiting waterproof roll

A technology of self-adhesive waterproof membrane and construction method, which is applied to roofs, roofs, and roof coverings using flexible materials. It can solve the problems of lack of perfect construction process standards and construction methods, and achieve the elimination of safety hazards, fast construction, and Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

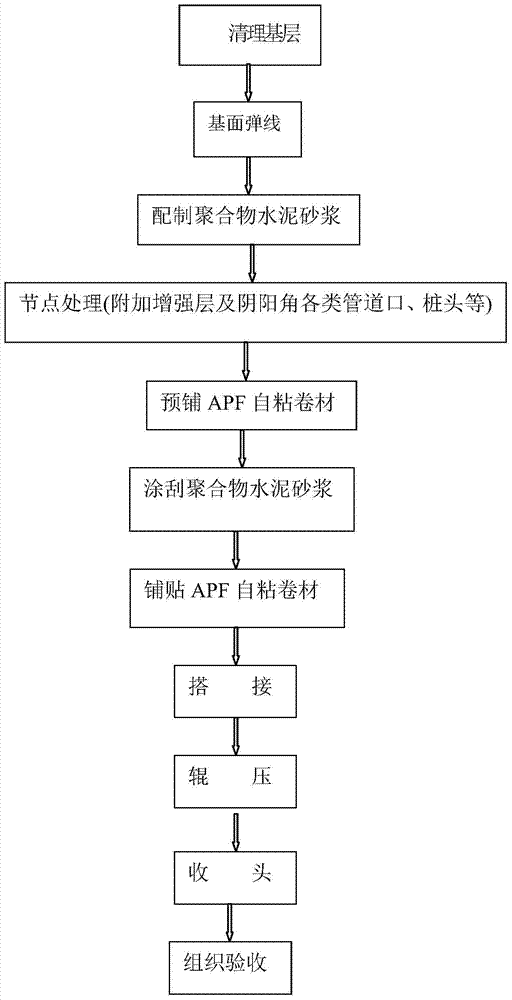

[0035] Plane construction: such as figure 1 as shown,

[0036] (1) Process according to the requirements of the base layer until the requirements of the base surface are met. Re-bounce the base line for laying the coiled material.

[0037] (2) Preparation of polymer cement mortar

[0038] The cement uses ordinary Portland cement above 32.5R grade to prepare polymer cement mortar. Put the mixture﹛polymer masterbatch: ordinary Portland cement=1:10 (weight ratio)﹜ in a container and stir evenly, then press water The ash ratio is 0.40 (weight ratio). After adding water, use an electric mixer to stir the mixture in the container for 1 to 2 minutes until it is uniform, and then stand it for 5 to 8 minutes for later use.

[0039] (3) Node processing

[0040] For details such as yin and yang corners, tube roots, etc., use special additional layer self-adhesive coils and cut yin and yang corner self-adhesive coils to perform additional reinforcement treatment on the corners on both...

Embodiment 2

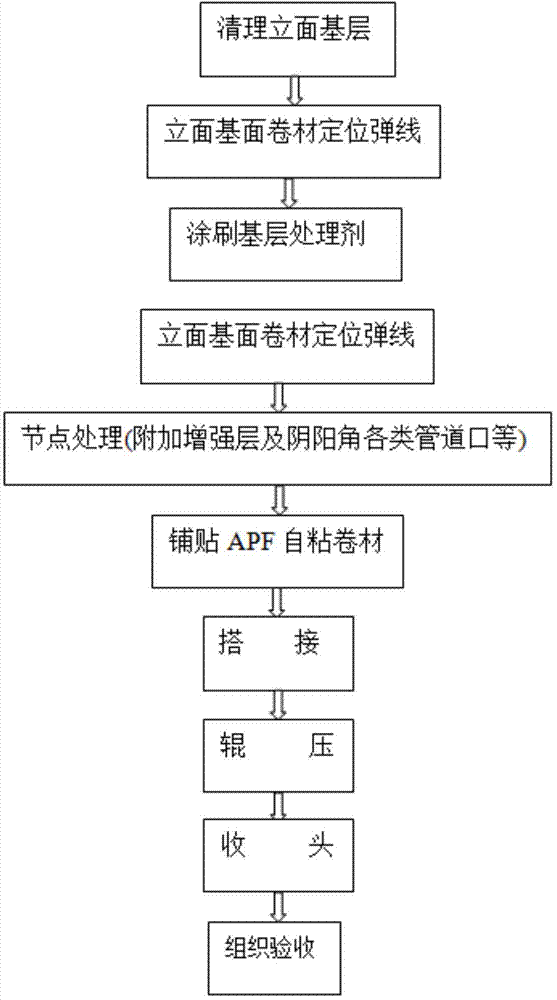

[0055] Façade construction: such as figure 2 as shown,

[0056] (1) Basic treatment:

[0057] According to the requirements of the base layer, proceed step by step until the requirements of the base surface are met, and then spring the baseline for laying the coiled material.

[0058] (2) Brush the base treatment agent:

[0059]Brush the base treatment agent on the treated base, and it is required to be thin and not exposed, and there must be no accumulation.

[0060] (3) Node processing:

[0061] The additional reinforcement layer and all kinds of pipe openings at the yin and yang corners shall be handled according to the design requirements. Closing method of self-adhesive coiled material for external walls: The end of self-adhesive coiled material for underground projects should be sealed to prevent the coiled material from opening. The ends are painted with polyurethane waterproof paint, and the sealing width is not less than 10mm. On the premise of ensuring the saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com