Method for improving tensile strength of collagen fiber material

A collagen fiber and tensile strength technology, applied in the field of medical biomaterials, can solve the problems of complex equipment, inability to realize large-scale sample preparation, and high operating conditions, and achieve high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

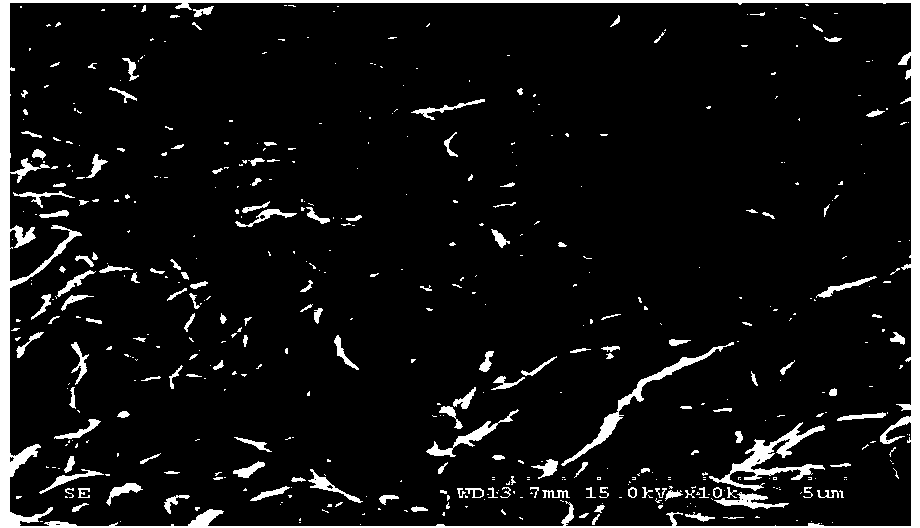

[0033] Under the condition of ice bath, 0.5 mol / L acetic acid aqueous solution was used to dissolve the type Ⅰ collagen extracted from grass carp skin. The pH of the collagen solution was adjusted to 7.0 by dialysis against the phosphate buffer solution at 4° C. to obtain a collagen solution with a concentration of 3 mg / mL. The collagen solution was transferred to a 10mL centrifuge tube, and centrifuged at 25°C and a relative centrifugal force of 3g for 5 minutes. Then the centrifuge tube was carefully and vertically taken out and vertically transferred to an incubator, and left to stand at 30° C. for 24 hours. Take out the collagen gel from the centrifuge tube, transfer it to 1% glutaraldehyde solution for cross-linking for 24 hours, then take out the collagen gel and wash it repeatedly with distilled water; then, at room temperature, fix one end of the collagen gel vertically, and continuously apply it to the other end Vertical downward pulling force of 0.7 N, after natural...

Embodiment 2

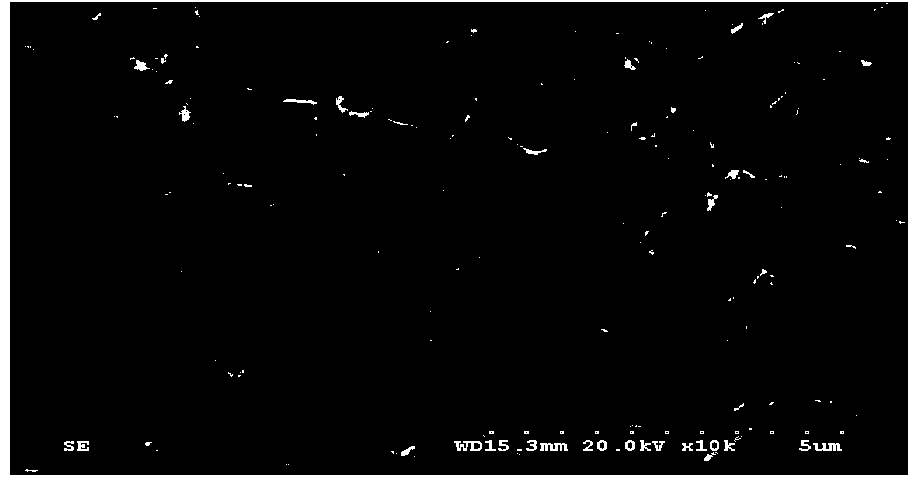

[0035] Under the condition of ice bath, 0.5 mol / L acetic acid aqueous solution was used to dissolve the type Ⅰ collagen extracted from grass carp skin. The pH of the collagen solution was adjusted to 7.0 by dialysis against the phosphate buffer solution at 4° C. to obtain a collagen acid solution with a concentration of 3 mg / mL. Transfer the collagen solution to a 10mL centrifuge tube and centrifuge at 25°C for 5 minutes at a centrifugal force of 3g. Then the centrifuge tube was carefully and vertically taken out and vertically transferred to an incubator, and left to stand at 30° C. for 24 hours. Take out the collagen gel from the centrifuge tube, transfer it to 1% glutaraldehyde solution for cross-linking for 24 hours, then take out the collagen gel and wash it repeatedly with distilled water; then transfer the collagen gel to a blast drying oven after natural drying at room temperature for 24 hours The collagen fiber material was obtained after drying at a temperature of 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com