Anticorrosion high-temperature resistant coating and preparation method thereof

A technology of high temperature resistant paint and compound rare earth, applied in the field of paint, can solve the problems of complex production process, short corrosion resistance time, long curing time, etc., and achieve the effects of simple production process, long corrosion resistance time and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

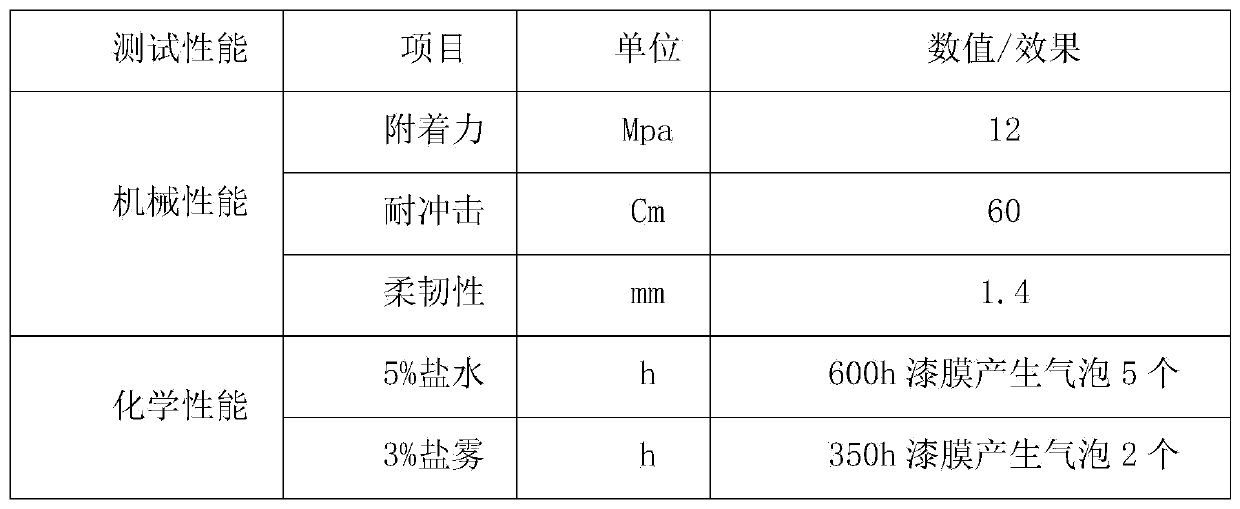

Embodiment 1

[0034] An anti-corrosion and high-temperature-resistant coating provided in this embodiment is composed of epoxy resin, petroleum resin, resin plasticizer, surfactant, solvent, multifunctional additive, composite rare earth and modified acrylic resin, Its composition in weight percent is: epoxy resin: 15%, petroleum resin: 35%, resin plasticizer: 12%, surfactant: 2%, solvent: 17%, multifunctional additive: 3%; Compound rare earth: 0.6%, the balance is modified acrylic resin, and the compound rare earth contains the following components by weight percentage: La: 22.4%, Y: 15.6%, Er: 15.2%, Yb: 9%, Tm: 18%, and the rest: Pr; The present embodiment also provides the preparation method of this anticorrosion and high temperature resistant coating, and this method is carried out according to the following steps:

[0035] Step (1): First, put the petroleum resin and solvent into the stirring tank for mixing, control the temperature in the stirring tank at 55°C, set the stirring speed...

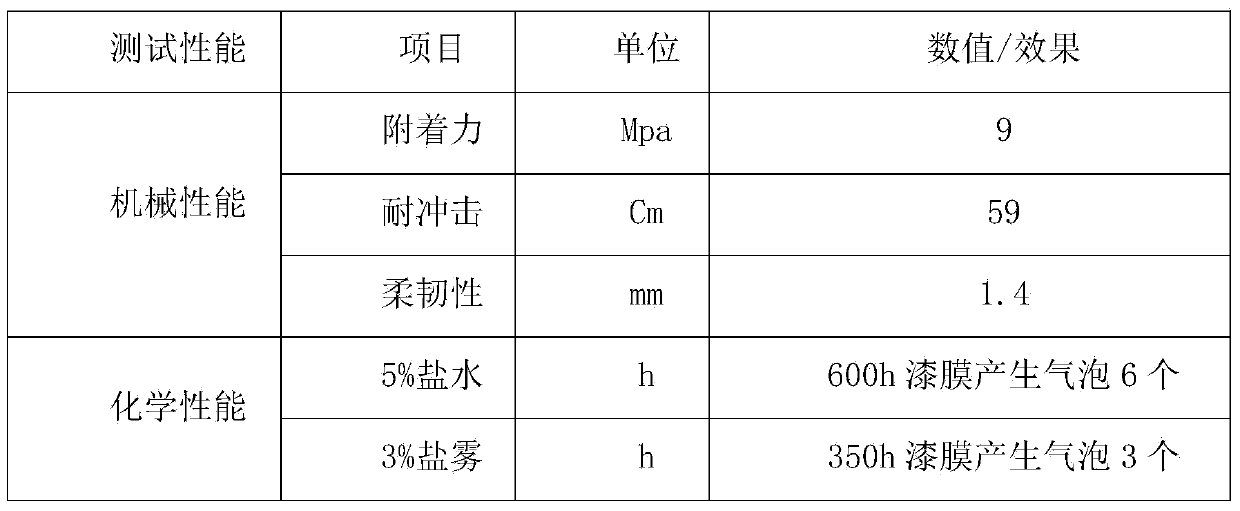

Embodiment 2

[0042] An anti-corrosion and high-temperature-resistant coating provided in this embodiment is composed of epoxy resin, petroleum resin, resin plasticizer, surfactant, solvent, multifunctional additive, composite rare earth and modified acrylic resin, Its composition in weight percent is: epoxy resin: 16%, petroleum resin: 37%, resin plasticizer: 14%, surfactant: 3%, solvent: 18%, multifunctional additive: 4%; Composite rare earth: 0.8%, the balance is modified acrylic resin, and the compound rare earth contains the following components by weight percentage: La: 22.5%, Y: 15.7%, Er: 15.3%, Yb: 10%, Tm: 19%, and the rest: Pr; The present embodiment also provides the preparation method of this anticorrosion and high temperature resistant coating, and this method is carried out as follows:

[0043] Step (1): First, put the petroleum resin and solvent into the stirring tank for mixing, control the temperature in the stirring tank at 53°C, set the stirring speed at 125r / min, and st...

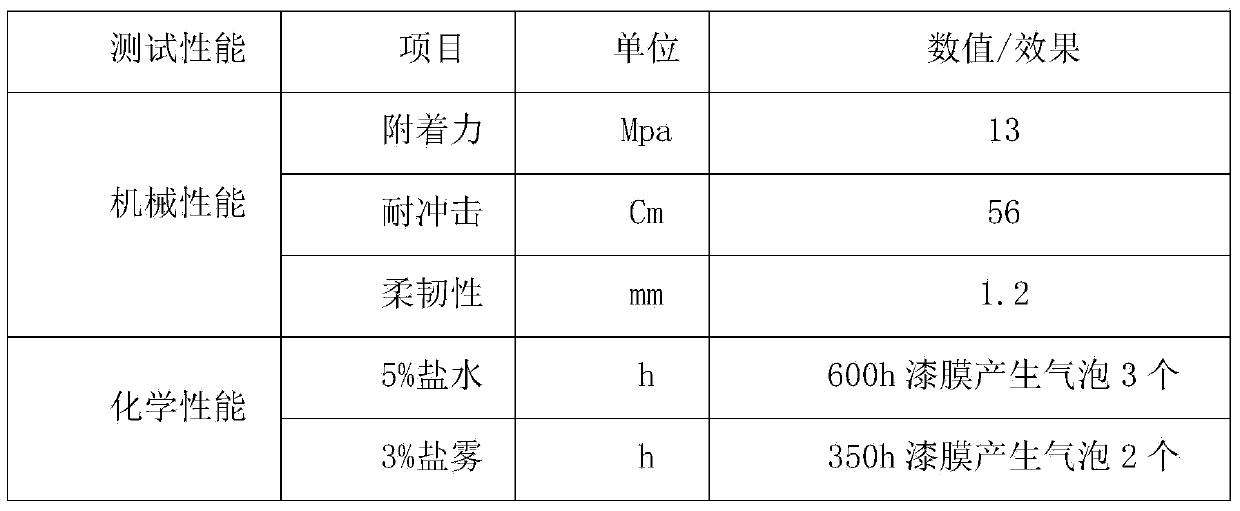

Embodiment 3

[0050] An anti-corrosion and high-temperature-resistant coating provided in this embodiment is composed of epoxy resin, petroleum resin, resin plasticizer, surfactant, solvent, multifunctional additive, composite rare earth and modified acrylic resin, Its weight percentage composition is: epoxy resin: 18%, petroleum resin: 38%, resin plasticizer: 15%, surfactant: 4%, solvent: 20%, multi-functional additive: 5%; Composite rare earth: 0.9%, the balance is modified acrylic resin, and the compound rare earth contains the following components by weight percentage: La: 22.6%, Y: 15.8%, Er: 15.5%, Yb: 11%, Tm: 20%, and the rest: Pr; The present embodiment also provides the preparation method of this anticorrosion and high temperature resistant coating, and this method is carried out as follows:

[0051] Step (1): First put the petroleum resin and solvent into the stirring tank for mixing, control the temperature in the stirring tank at 52°C, set the stirring speed at 120r / min, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com