Foaming material for preparing functional insole and functional insole

A foaming material and functional technology, applied in the field of insole preparation, can solve the problems of limited health care effect, complex production process, limited use occasions, etc., and achieve the effects of easy absorption and perspiration, simple process and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

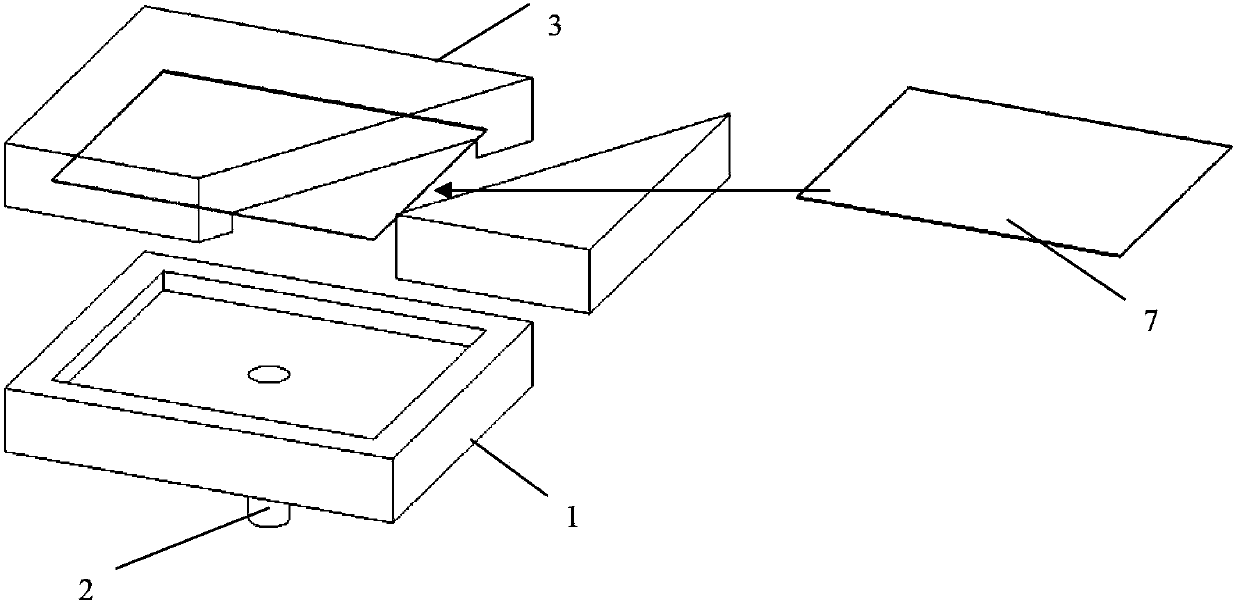

[0089] Using HN395A / B silicone foam material from Shanghai Hahn Chemical Technology Co., Ltd., components A and B are uniformly mixed at a ratio of 1:2.5 and placed in a foaming mold. Free foaming at 20°C without compression. The obtained foam material for making insoles, The foam material contains about 75% (mass) of organosiloxane segment structure - (Si-O) n -; and has a strong absorption peak between 1000 and 1100cm-1 in the infrared spectrum, and its cell structure is as figure 1 .

[0090] Its material test indicators are as follows:

[0091] Density (g / cm3) 0.20;

[0092] Hardness (FO) 40;

[0093] Tensile strength (mpa) 0.19;

[0094] Elongation at break (%) 135;

[0095] Tear strength (N / cm) 1.2;

[0096] Compression set (%) <5; (50% compression, 72h23℃)

[0097] Opening rate (%) 89.

Embodiment 2

[0099] Using HN395A / B silicone foam material from Shanghai Hahn Chemical Technology Co., Ltd., components A and B are uniformly mixed at a ratio of 1:2.5, placed in a foaming mold, compressed at 20°C by 1.15 times and foamed, and the obtained foam material for making insoles, The foam material contains about 75% (mass) of organosiloxane segment structure - (Si-O) n -; and has a strong absorption peak between 1000 and 1100cm-1 in the infrared spectrum, and its cell structure is as figure 2 .

[0100] Its material test indicators are as follows:

[0101] Density (g / cm3) 0.23;

[0102] Hardness (F0) 86;

[0103] Tensile strength (mpa) 0.31;

[0104] Elongation at break (%) 115;

[0105] Tear strength (N / cm) 1.4;

[0106] Compression set (%) <3; (50% compression, 72h23℃)

[0107] Opening rate (%) 85.

Embodiment 3

[0109] Using HN395A / B silicone foam material from Shanghai Hahn Chemical Technology Co., Ltd., components A and B are uniformly mixed at a ratio of 1:2.5 and placed in a foaming mold. Compressed at 20°C for 1.3 times of foaming, the obtained foam material for making insoles, The foam material contains about 75% (mass) of organosiloxane segment structure - (Si-O) n -; and has a strong absorption peak between 1000 and 1100cm-1 in the infrared spectrum, and its cell structure is as image 3 .

[0110] Its material test indicators are as follows:

[0111] Density (g / cm3) 0.26;

[0112] Hardness (FO) 93;

[0113] Tensile strength (mpa) 0.33;

[0114] Elongation at break (%) 108;

[0115] Tear strength (N / cm) 1.8;

[0116] Compression set (%) <2; (50% compression, 72h23℃)

[0117] Opening rate (%) 86.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com