Ceramic product, preparation method thereof, prepared inner container of drinking fountain and drinking fountain

A technology of ceramic products and drinking fountains, applied in the field of ceramics, can solve the problems of cleaning and inconvenient use, and achieve the effects of saving freight, adjusting metabolism, and easy source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

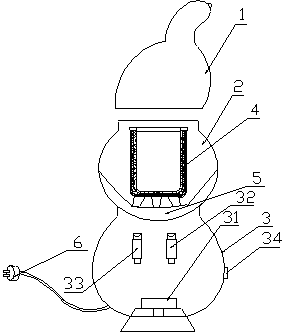

Image

Examples

preparation example Construction

[0032] A method for preparing a ceramic product, comprising the steps of:

[0033] (1) Take each raw material according to the stated ratio, add it into a ball mill for ball milling for 18-22 hours to reach a fineness of 120 mesh, and obtain a mixed slurry;

[0034] (2) Pour the mixed slurry in step (1) into the prepared plaster mold, place it at 35 degrees for 1-2 hours and continue to place it for 3-5 days;

[0035] (3) Remove the dried green body from the mold, add water for 3-5 times, and polish the burrs to make the green body clean and smooth;

[0036] (4) Put the green body into the kiln, raise the temperature to 1200-1300 degrees within 3 hours, and fire for 8-10 hours. After the firing is completed, naturally cool to room temperature to obtain the finished product.

[0037] Fill the finished product with water and let it stand for 1-2 hours, collect the seepage water, and change weak alkaline or neutral water into weak alkaline water.

[0038] The present invention ...

Embodiment 1

[0046] Embodiment 1 Utilizes purple sand pottery of the present invention to prepare water dispenser liner

[0047] Take 10 parts of feldspar, 20 parts of purple sandstone, 15 parts of stick clay, 30 parts of quartz, 20 parts of clay, 15 parts of meteorite, 15 parts of medical stone and 10 parts of Nishan stone.

[0048] Its preparation method is as follows:

[0049] (1) Take each raw material according to the stated ratio, add it into a ball mill for ball milling for 22 hours to reach a fineness of 120 mesh, and obtain a mixed slurry;

[0050] (2) Pour the mixed slurry in step (1) into the plaster mold of the inner tank of the water dispenser, place it for 2 hours and then continue to place it for 5 days to dry at room temperature

[0051] (3) Remove the dried green body from the mold, replenish water 5 times, and polish the burrs to make the green body clean and smooth;

[0052] (4) Put the green body into the kiln, raise the temperature to 1260 degrees within 3 hours, and...

Embodiment 2

[0055] Embodiment 2 Utilizes purple sand pottery of the present invention to prepare teacup liner

[0056] Take 25 parts of feldspar, 10 parts of purple sandstone, 10 parts of stick clay, 15 parts of quartz, 15 parts of clay, 10 parts of meteorite, 30 parts of medical stone and 30 parts of Nishan stone.

[0057] Its preparation method is as follows:

[0058] (1) Take each raw material according to the stated ratio, add it into a ball mill for ball milling for 20 hours to reach a fineness of 120 mesh, and obtain a mixed slurry;

[0059] (2) Pour the mixed slurry in step (1) into the plaster mold of the prepared teacup liner, place it for 2 hours and then continue to place it for 4 days to dry at room temperature;

[0060](3) Remove the dried green body from the mold, add water 4 times, and polish the burrs to make the green body clean and smooth;

[0061] (4) Put the green body into the kiln, raise the temperature to 1230 degrees within 3 hours, and fire for 9 hours in total....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com