Gypsum-based plastering mortar and preparation method thereof

A plastering mortar and gypsum-based technology, which is applied in the field of building materials, can solve the problems of a large volume of materials, a large amount of material used, and a thick plastering layer, and achieve the effects of low volume proportion, less usage, and suitable hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] For the gypsum-based plastering mortar of this embodiment, the mass percentages of each component are: 16.4% gypsum, 6.7% cement, 75.5% sand, and 1.4% additive; the sand is a mixture of furnace slag and industrial waste slag, and the additive includes emulsion and a stabilizer, the gypsum is a mixture of desulfurized gypsum and titanium gypsum, and the mass ratio of the emulsion to the stabilizer is 4:1.

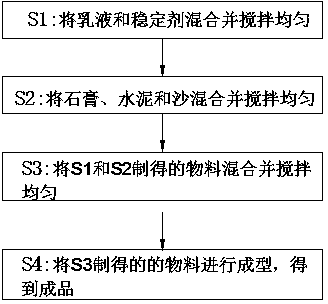

[0019] The preparation method of the gypsum base plaster mortar of this embodiment is:

[0020] S1. Mix the emulsion and the stabilizer and stir evenly for 3 minutes;

[0021] S2, mixing gypsum, cement and sand and stirring evenly for 8 minutes;

[0022] S3, mixing the materials prepared by S1 and S2 and stirring evenly;

[0023] S4. Molding the material obtained in S3 to obtain a finished product.

Embodiment 2

[0025] For the gypsum-based plastering mortar of this embodiment, the mass percentages of each component are: 19.5% gypsum, 7.5% cement, 71.3% sand, and 1.7% additive; the sand is a mixture of river sand and mountain sand, and the additive includes emulsion and a stabilizer, the gypsum is a mixture of desulfurized gypsum and fluorine gypsum, and the mass ratio of the emulsion to the stabilizer is 6:1.

[0026] The preparation method of the gypsum base plaster mortar of this embodiment is:

[0027] S1. Mix the emulsion and the stabilizer and stir evenly for 2 minutes;

[0028] S2, mixing gypsum, cement and sand and stirring evenly for 12 minutes;

[0029] S3, mixing the materials prepared by S1 and S2 and stirring evenly;

[0030] S4. Molding the material obtained in S3 to obtain a finished product.

Embodiment 3

[0032] For the gypsum-based plastering mortar of the present embodiment, the mass percentages of each component are: 17.3% gypsum, 7.4% cement, 73.8% sand, and 1.5% additive; the sand is slag, and the additive includes emulsion and stabilizer. The gypsum is electric gypsum, and the mass ratio of the emulsion and the stabilizer is 5:1.

[0033] The preparation method of the gypsum base plaster mortar of this embodiment is:

[0034] S1. Mix the emulsion and the stabilizer and stir evenly for 5 minutes;

[0035] S2, mixing gypsum, cement and sand and stirring evenly for 10 minutes;

[0036] S3, mixing the materials prepared by S1 and S2 and stirring evenly;

[0037] S4. Molding the material obtained in S3 to obtain a finished product.

[0038] Compared with the traditional cement mortar, the gypsum-based plastering mortar of the above three embodiments has less material usage per unit area, lower volume specific gravity of the material, and the product is a flexible material w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com