Preparation method of fluorinated graphene

A technology of fluorinated graphene and graphene, which is applied in the field of preparation of fluorinated graphene materials, can solve problems such as the inability to realize the regulation of fluorine content, large production safety hazards, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

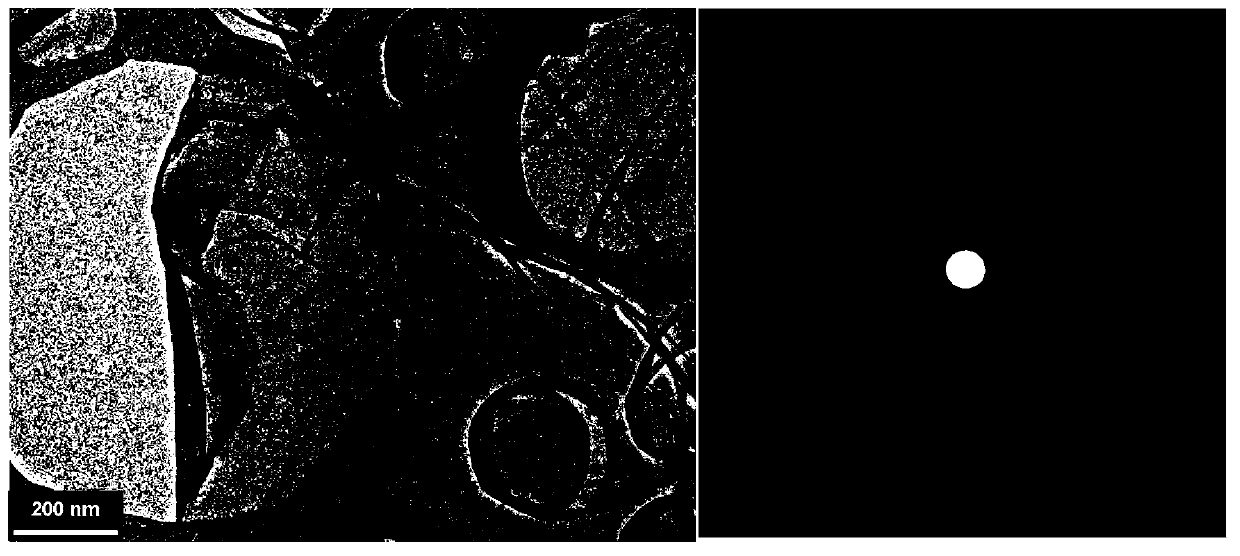

Image

Examples

preparation example Construction

[0131] Preparation of fluorinated graphene

[0132] The invention provides a kind of preparation method of fluorinated graphene, described method comprises:

[0133] Use fluorinating reagent to react with graphene oxide to obtain fluorinated graphene.

[0134] In another preferred example, the mass ratio of fluorinating reagent to graphene oxide is: fluorinating reagent: graphene oxide = 0.001-500:1, preferably fluorinating reagent: graphene oxide = 0.1-100:1.

[0135] Preferably, after the reaction is completed, a quenching agent can be optionally added to quench the reaction system. The quenching agents include (but are not limited to): alcohols, thiols, amines, ketones, amides, water, or combinations thereof.

[0136] In another preferred embodiment, the quencher is selected from the group consisting of methanol, ethanol, isopropanol, or combinations thereof.

[0137] The reaction can be carried out in an inert solvent. Preferably, the inert solvent is selected from the ...

Embodiment 1

[0158] Weigh 120 mg of graphene oxide and disperse it in 120 mL of tetrahydrofuran, add 2 mL of diethylaminosulfur trifluoride (DAST), stir at room temperature for 3 days, then add 50 mL of methanol to the reaction system to quench the reaction. Then the reaction system was filtered through a 0.22-micron polytetrafluoroethylene membrane, the filter cake was washed with a solvent, the filter cake was collected and vacuum-dried to obtain a black powder product, the fluorine content was determined to be 3.1% by elemental analysis.

Embodiment 2

[0160] The preparation method is basically the same as in Example 1, except that the solvent used is pyridine, and the fluorine content of the obtained product is determined to be 5.2% by elemental analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com