Fuel tank depressurization before refueling a plug-in hybrid vehicle

A technology for hybrid vehicles and fuel tanks, applied in hybrid vehicles, adding non-fuel substances to fuel, electric vehicle charging technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

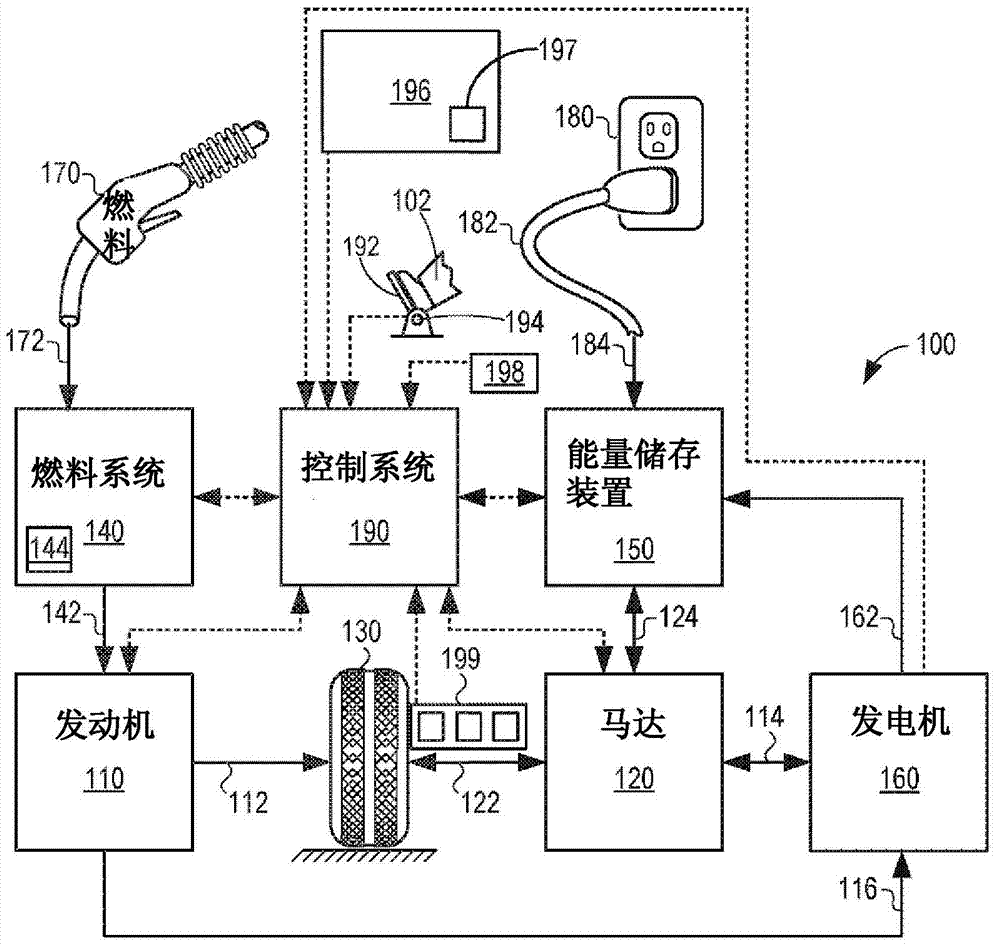

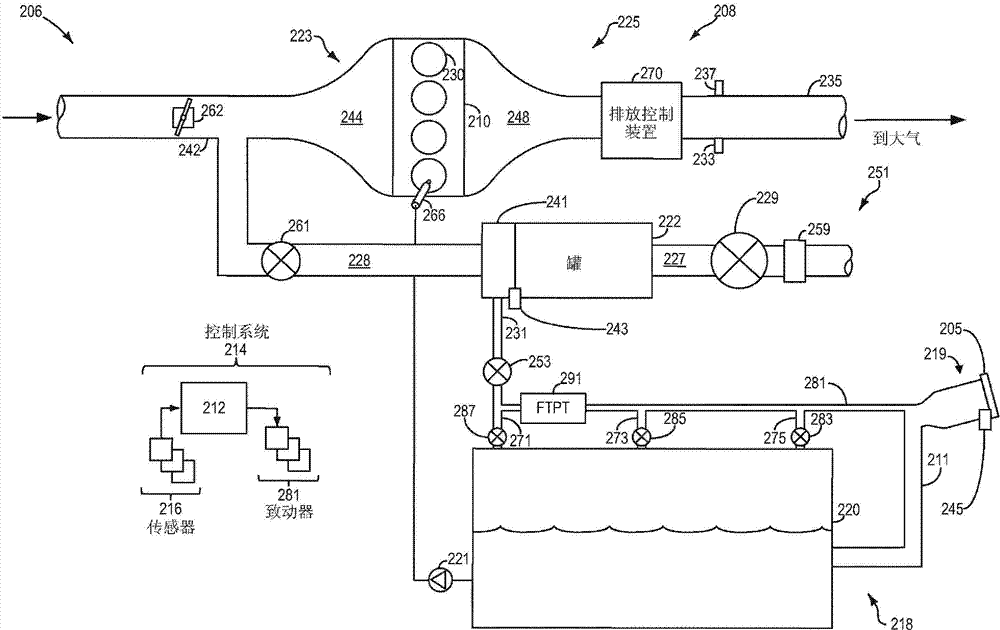

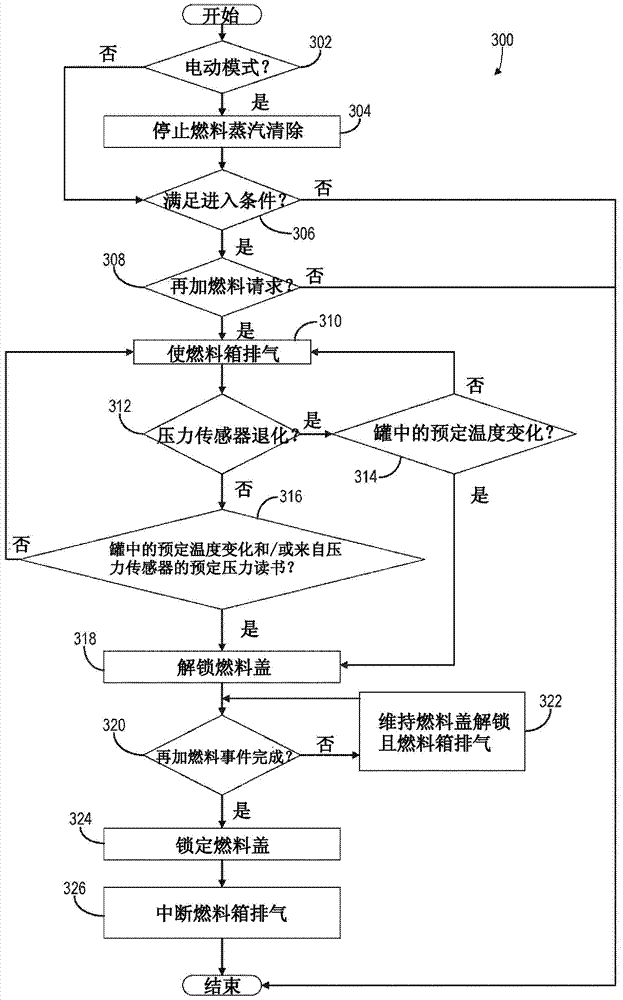

[0021] The following description relates to the locking mechanism used to control the fuel filler cap for vehicles (for example, figure 1 A system and method for refueling a hybrid vehicle as shown in . Such as figure 2 As shown, the vehicle includes an engine system having a fuel system including a fuel tank and a fuel filler cap having a locking mechanism configured to prevent the fuel filler cap from being opened. The fuel tank may be depressurized to prevent fuel from draining from the filler tube during refueling. Therefore, the fuel cap can remain locked until the fuel tank is sufficiently depressurized. as referenced below image 3 and Figure 4 As stated, following a refueling request, the fuel tank may be vented to the fuel vapor canister, and the temperature in the fuel vapor canister may be monitored to assist in determining when the fuel tank is sufficiently depressurized to perform a refueling. For example, a predetermined temperature change in the fuel vapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com