Flue gas desulfurization method and system

A desulfurization system and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of inability to solve the problem of circulating steam mass balance, strong corrosiveness of tower top steam, and difficulty in recovering sulfur resources. , to achieve good flue gas desulfurization effect, conducive to temperature maintenance, and the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

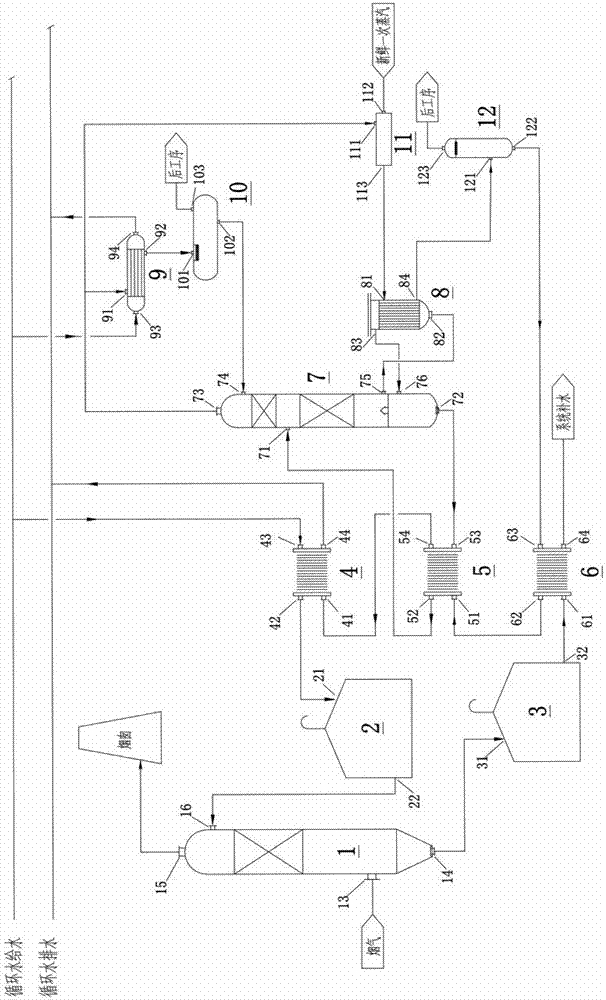

[0035] A kind of flue gas desulfurization method of the present invention, adopts such as figure 1 The flue gas desulfurization system is shown, but the flue gas desulfurization method is not limited to the use of the flue gas desulfurization system. The flue gas treated in this embodiment contains SO 2 lead smelting reduction furnace flue gas, but not limited to such flue gas. The flue gas desulfurization method of this embodiment specifically includes the following steps:

[0036] (a) The flue gas of the lead smelting reduction furnace enters the flue gas desulfurization system after being washed and cooled by the pretreatment system, and enters the absorption tower 1 from the lower part of the flue gas desulfurization system, and the temperature of the entering tower is 42°C. The flue gas in the absorption tower 1 is in countercurrent contact with the poor absorption liquid (usually the absorption liquid or ionic liquid containing organic amine compounds) sprayed from the...

Embodiment 2

[0050] A kind of flue gas desulfurization method of the present invention, adopts such as figure 1 In the flue gas desulfurization system shown, the treated flue gas contains SO 2 The lead smelting reduction furnace flue gas specifically includes the following steps:

[0051] (a) The flue gas from the lead smelting reduction furnace enters the flue gas desulfurization system after being washed and cooled by the pretreatment system, and enters the absorption tower 1 from the lower part of the absorption tower 1 in the flue gas desulfurization system. The flue gas is in countercurrent contact with the poor absorption liquid (usually the absorption liquid containing organic amine compounds, or ionic liquid) sprayed down from the upper part of the absorption tower 1, so that the poor absorption liquid absorbs the SO in the flue gas 2 , form absorption liquid rich liquid, store in rich liquid storage tank 3, remove SO 2 The final flue gas is discharged from the top of the absorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com