Bead stringing machine capable of stringing different beads and working method of bead stringing machine capable of stringing different beads

A technology of bead threading machine and beads, which is applied in the field of bead threading machine, can solve problems such as low processing efficiency, damage, and complexity, and achieve the effects of improving performance, ensuring processing quality, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

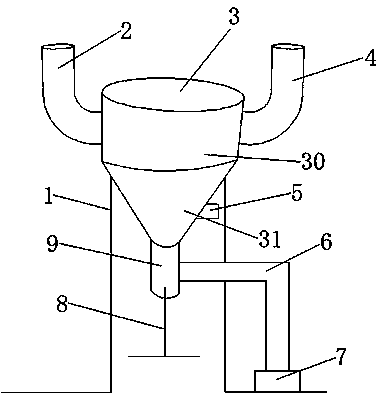

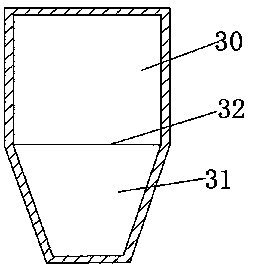

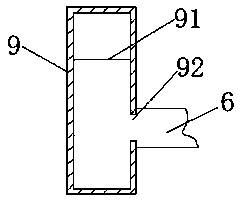

[0021] refer to Figure 1 to Figure 4 As shown, a bead threading machine capable of wearing different beads includes a bracket 1, a hopper 3 arranged on the bracket 1, a first feeding pipe 2 arranged on the left side of the hopper 3, and a first feeding pipe 2 arranged on the right side of the hopper 3 The second feed pipe 4, and the bead drop pipe 9 arranged below the hopper 3, and the air pipe 6 connected to the bead pipe 9, and the blower fan 7 arranged at the end of the air pipe 6, and the bead drop pipe 9 below The bead-piercing rod 8, and the gravity sensor 5 arranged on the right side of the hopper 3; the hopper 3 is divided into an upper hopper 30 and a lower hopper 31, and a first partition 32 arranged in the middle of the upper hopper 30 and the lower hopper 31 The bead drop tube 9 is provided with a second partition 91 and an air outlet 92 located on the right side of the bead drop tube 9; the second partition 91 is provided with an inductor (not shown); The air ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com