Microelement sucrose complex feed additive as well as preparation method and application thereof

A technology of sucrose complexes and feed additives, which is applied in animal feed, animal feed, applications, etc., can solve the problems of increasing the burden on animal bodies and the environment, difficult absorption and utilization of nutrients, and reduction of absorption and utilization, so as to improve daily growth weight, improve meat quality, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

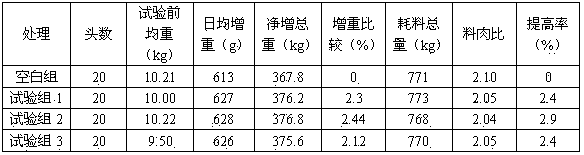

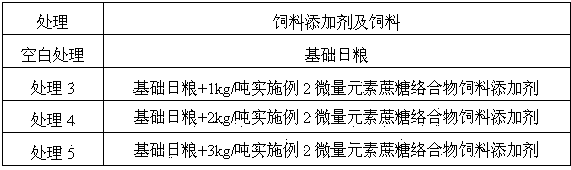

Examples

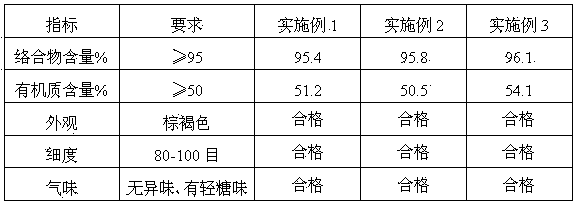

Embodiment 1

[0038] Put 20 moles of sucrose molasses into the 5000L reactor (the water content of sucrose molasses is 18%), turn on the heating, raise the temperature to 85°C, keep the temperature at 85-105°C, and turn on the stirring equipment at the same time, the stirring speed is 80r / min, 2 moles of copper sulfate crushed through a 100 mesh sieve were added to the reactor in 2 batches, and reacted for 1 hour; then 2 moles of zinc sulfate passed through a 80 mesh sieve were added, added in two batches, and reacted for 1.5 hours; Add in two batches and stir for 2 hours; finally add 2 moles of ferrous sulfate passing through a 80-mesh sieve, and react for 1.5 hours. The material is introduced into a stainless steel pool, cooled, and precipitated; after completion, the precipitate is put into a centrifuge for dehydration, and then dried by an airflow dryer, the temperature is controlled at 120°C, cooled and sieved to obtain a complex of sucrose and trace elements (sucrose copper , the sum ...

Embodiment 2

[0040] Put 50 moles of sucrose molasses into the 5000L reactor (the water content of sucrose molasses is 30%), turn on the heating, raise the temperature to 85°C, keep the temperature at 85-105°C, and turn on the stirring equipment at the same time, the stirring speed is 80r / min, 5 moles of copper sulfate crushed through a 100 mesh sieve were added to the reactor in 2 batches, and reacted for 2 hours; then 5 moles of zinc sulfate passed through a 80 mesh sieve were added, added in two batches, and reacted for 2 hours; Add in two batches and stir for 2 hours; add 5 moles of manganese sulfate passed through a 80-mesh sieve, and react for 1.5 hours; finally, add 2 moles of calcium sulfate, 2 moles of magnesium sulfate and 2 moles of molybdenum sulfate, stir for 1 hour, and the reaction is complete. The material is introduced into a stainless steel pool, cooled, and precipitated; after completion, the precipitate is put into a centrifuge for dehydration, and then dried by an airflo...

Embodiment 3

[0042] Put 100 moles of sucrose molasses into the 5000L reactor (the water content of sucrose molasses is 50%), turn on the heating, raise the temperature to 85°C, keep the temperature at 85-105°C, and turn on the stirring equipment at the same time, the stirring speed is 80r / min, 10 moles of copper sulfate crushed through a 100 mesh sieve were added to the reactor in 2 batches, and reacted for 2 hours; then 10 moles of zinc sulfate passed through a 100 mesh sieve were added, added in two batches, and reacted for 2 hours; Add in two batches and stir for 2 hours; add 10 moles of manganese sulfate passed through a 100-mesh sieve and react for 1.5 hours; finally, add 1 mole of calcium sulfate, 2 moles of magnesium sulfate and 2 molybdenum sulfate, stir for 2 hours, and the reaction is complete. The material is introduced into a stainless steel pool, cooled, and precipitated; after completion, the precipitate is put into a centrifuge for dehydration, and then dried by an airflow dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com