High-power IGBT (insulated gate bipolar transistor) driver

A driver, high-power technology, applied in the field of driver, can solve the problems of transformer manufacturing process and structure difficulties, and achieve the effects of being beneficial to protection, light weight, and easy to design and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings.

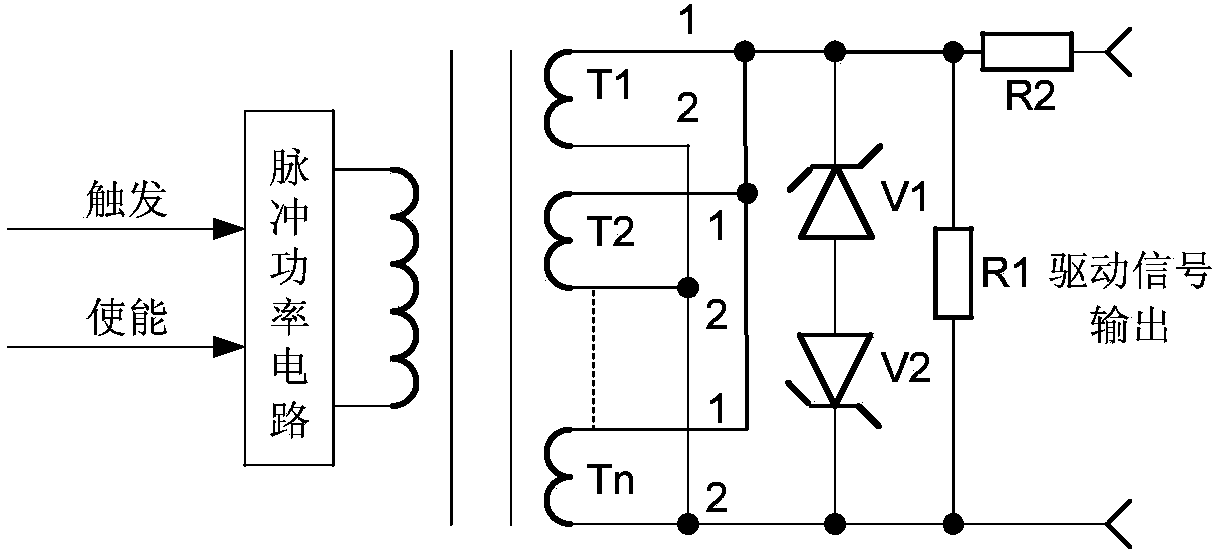

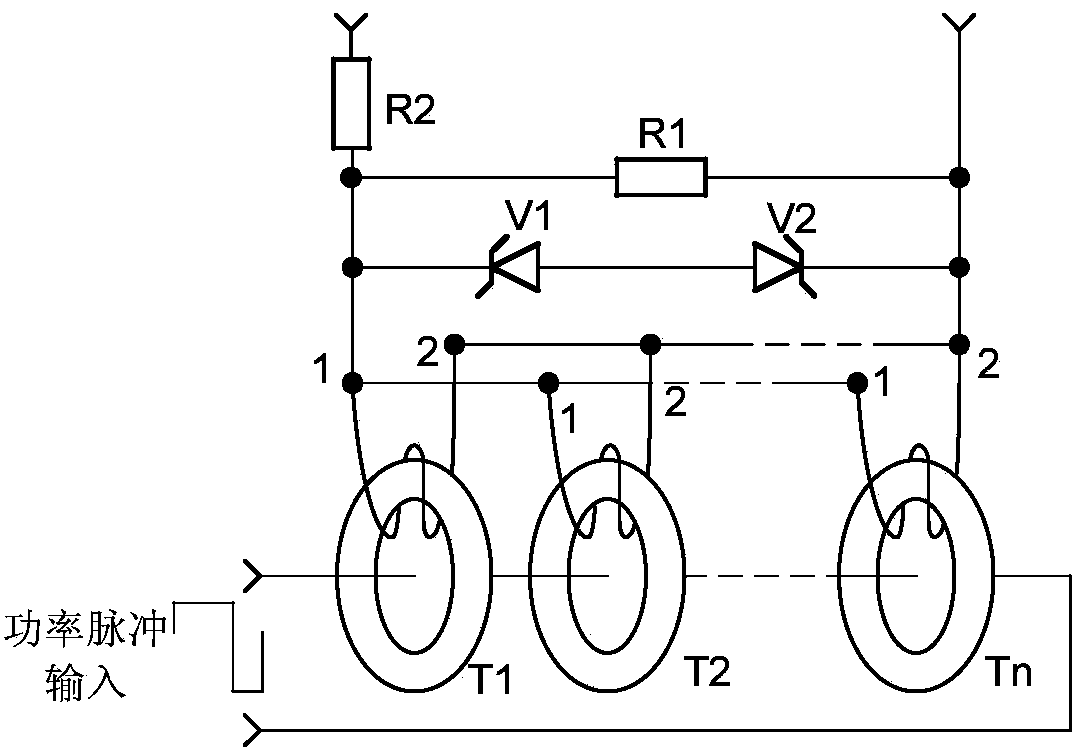

[0022] Such as Figure 1 to 2 As shown, the present invention provides a high-power IGBT driver, including a pulse power circuit, n transformers T1 to Tn, where n≥2, and a clamping and current limiting circuit; the clamping and current limiting circuit Including voltage regulator tube V1 and voltage regulator tube V2, and resistor R1 and resistor R2;

[0023] One cable passes through the center of all n transformers and serves as the primary winding of all n transformers;

[0024] Each transformer has a separate secondary winding, the winding direction of all secondary windings is the same, the number of turns is the same, and the secondary windings of all n transformers are all connected in parallel; one end of the secondary winding of each transformer is connected to The 1 ends of the other n-1 transformer secondary windings are connected together, and the 2 ends of each tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com