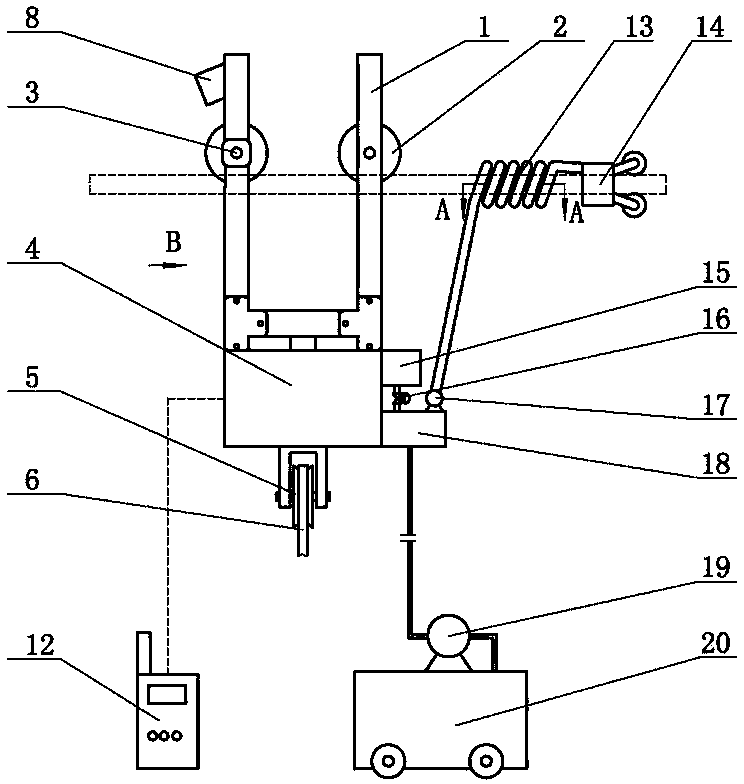

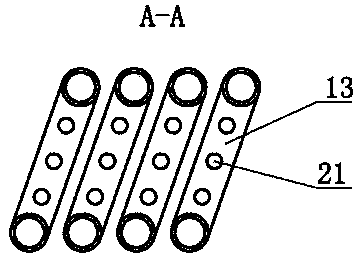

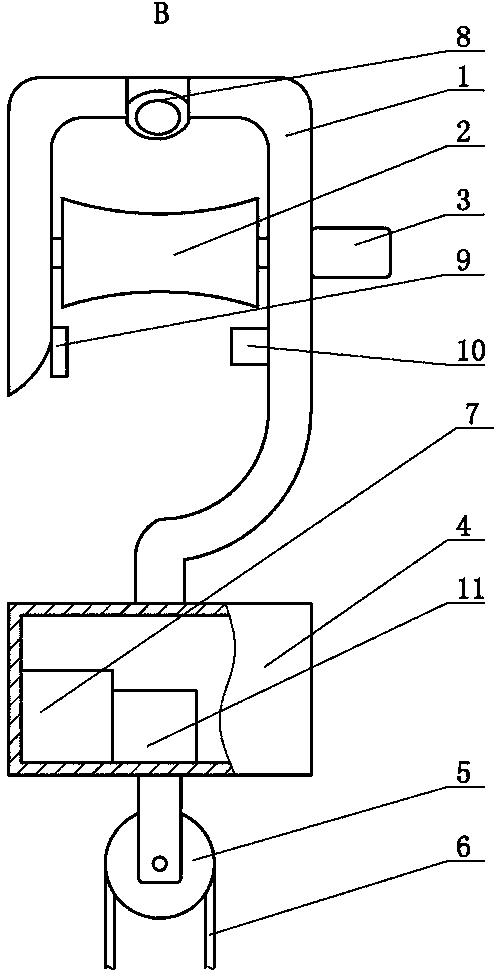

Live working remote control sliding device

A technology for live work and skids, applied in the direction of overhead lines/cable equipment, etc., can solve the problem that the mechanical cleaning device is easily entangled, and achieve the effect of saving cleaning time, low manufacturing cost, and reducing line failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention also provides a preparation method of a charged cleaning agent for electrical equipment, the steps are as follows:

[0017] ①Add 1-2 parts of polyvinylpyrrolidone and 1-3 parts of pentaerythritol to the mixture of 15-25 parts of propylene glycol butyl ether and 4-6 parts of N-methyl-2-pyrrolidone, stir and heat up to 50-70℃ , keep warm for 1-2 hours, cool to 20-30°C to obtain mixed solution A, set aside;

[0018] ②Add 1-3 parts of dodecyl dimethyl quaternary ammonium betaine to the mixture of 10-20 parts of triethanolamine and 3-5 parts of ethylene glycol monobutyl ether, stir and heat up to 70-90°C , after 1-2 hours, cool to 20-30°C to obtain mixed solution B, set aside;

[0019] ③ mix the mixed solution A obtained in step ①, the mixed solution B obtained in step ②, 20-30 parts of trichlorethylene, 15-25 parts of carbon tetrachloride and 5-10 parts of N-fatty acyl glutamic acid ethanolamine salt to obtain Charge cleaning agent for electrical equ...

Embodiment 1

[0026] A charged cleaning agent for electrical equipment, consisting of the following components in parts by weight: 20 parts of trichlorethylene, 25 parts of carbon tetrachloride, 15 parts of propylene glycol butyl ether, 10 parts of triethanolamine, N-fatty acyl glutamic acid 5 parts of ethanolamine salt, 1 part of polyvinylpyrrolidone, 1 part of pentaerythritol, 4 parts of N-methyl-2-pyrrolidone, 3 parts of ethylene glycol monobutyl ether and 1 part of dodecyl dimethyl betaine.

Embodiment 2

[0028] A charged cleaning agent for electrical equipment, consisting of the following components in parts by weight: 30 parts of trichlorethylene, 15 parts of carbon tetrachloride, 25 parts of propylene glycol butyl ether, 20 parts of triethanolamine, N-fatty acyl glutamic acid 10 parts of ethanolamine salt, 2 parts of polyvinylpyrrolidone, 3 parts of pentaerythritol, 6 parts of N-methyl-2-pyrrolidone, 5 parts of ethylene glycol monobutyl ether and 3 parts of dodecyl dimethyl betaine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com