Automatic equipment for packaging battery

A technology for automated equipment and batteries, applied in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve problems such as difficult storage, and achieve the effect of solving difficult storage and convenient batch processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

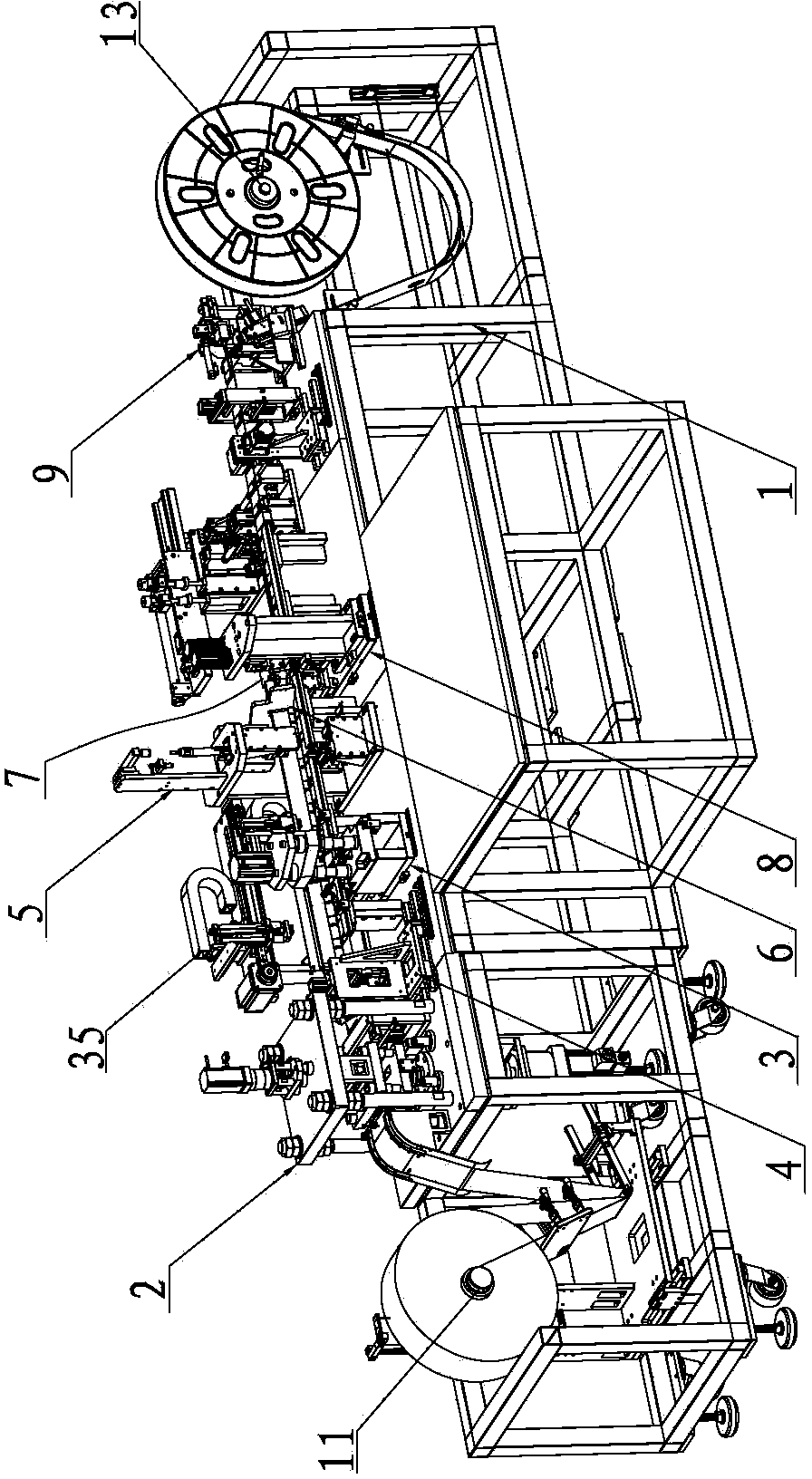

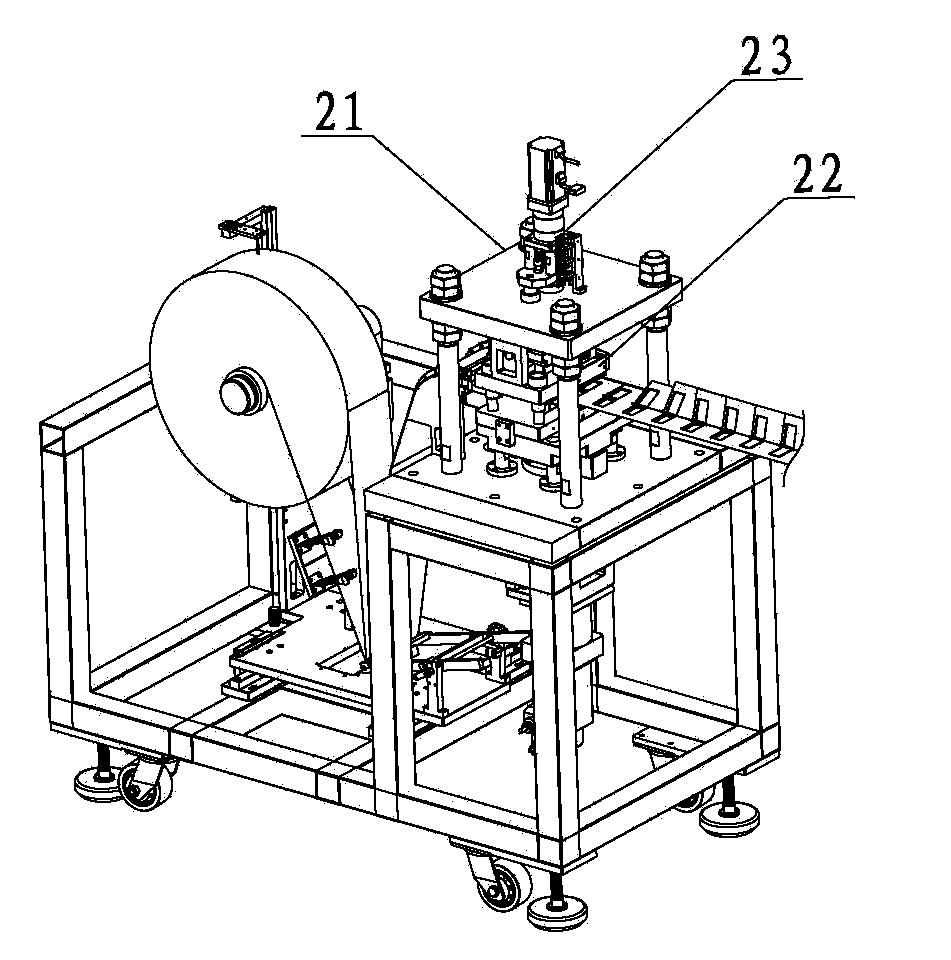

[0033] see Figure 1 to Figure 15 , an automated device for packaging batteries, comprising a support frame 1, one end of the support frame 1 is provided with a discharge shaft 11, and the discharge direction of the discharge shaft 11 is provided with a device for punching out a strip 15 into a shape The stamping device 2 of the pit 152, the discharge end of the stamping device 2 is provided with a cutting device 24 for cutting a part of the strip 15 to form the covering part 151, and the discharge end of the cutting device 24 is set There is a bending device 4 for bending the covering part 151, the discharge end of the bending device 4 is provided with a walking support 12 for the strip material 15 to move, and the walking support 12 is provided with a hem opening 121 in turn And the top seal 122, the walking support 12 is provided with a battery cell 161 (Note: Un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com