Nanoimprinting method and device of array type micro-structure

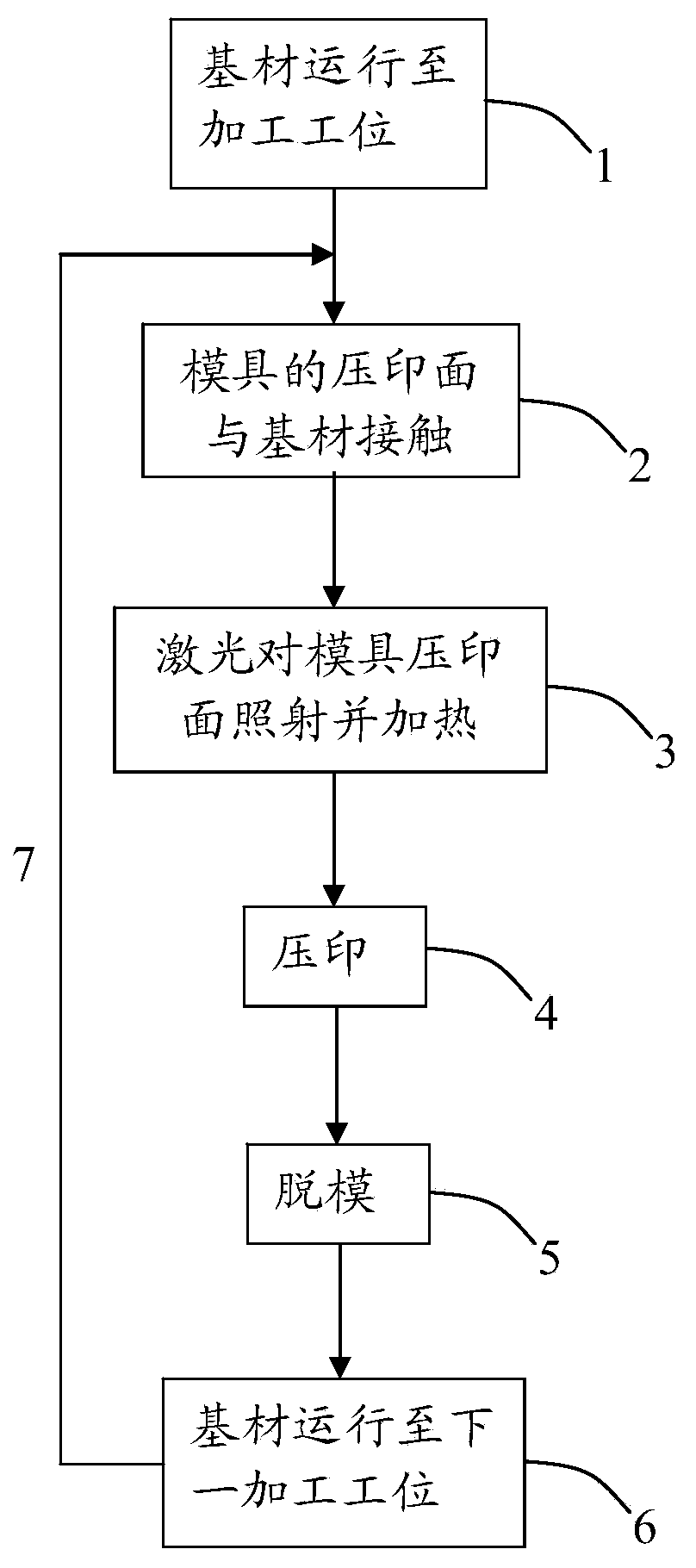

A nano-imprinting and micro-structure technology, applied in the fields of nanotechnology, optics, opto-mechanical equipment, etc., can solve the problems of low processing efficiency, and achieve the effect of fast heating speed, accurate construction and precise control of heating area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] PMMA is used as the processing substrate, and the metal nickel material grating with a line width of 500nm is used as the needle tip indenter, and the microstructure grating array template is processed by the needle nanoimprinting method.

[0052] Specifically, the processing substrate is fixed on the workbench, and the imprinting surface of the microstructure mold having the above-mentioned needlepoint indenter is controlled to be in contact with the area to be processed; the heating laser is turned on, and the laser beam is focused and irradiated on the surface of the embossing surface , the focal spot size is 200um, the surface temperature rises through energy radiation, and the surface processing temperature is about 200°C.

[0053] When the surface temperature of the embossed surface reaches the processing temperature of the substrate, the embossing pressure is applied to the imprinted surface of the microstructure mold, and the pressure is maintained to promote the s...

Embodiment 2

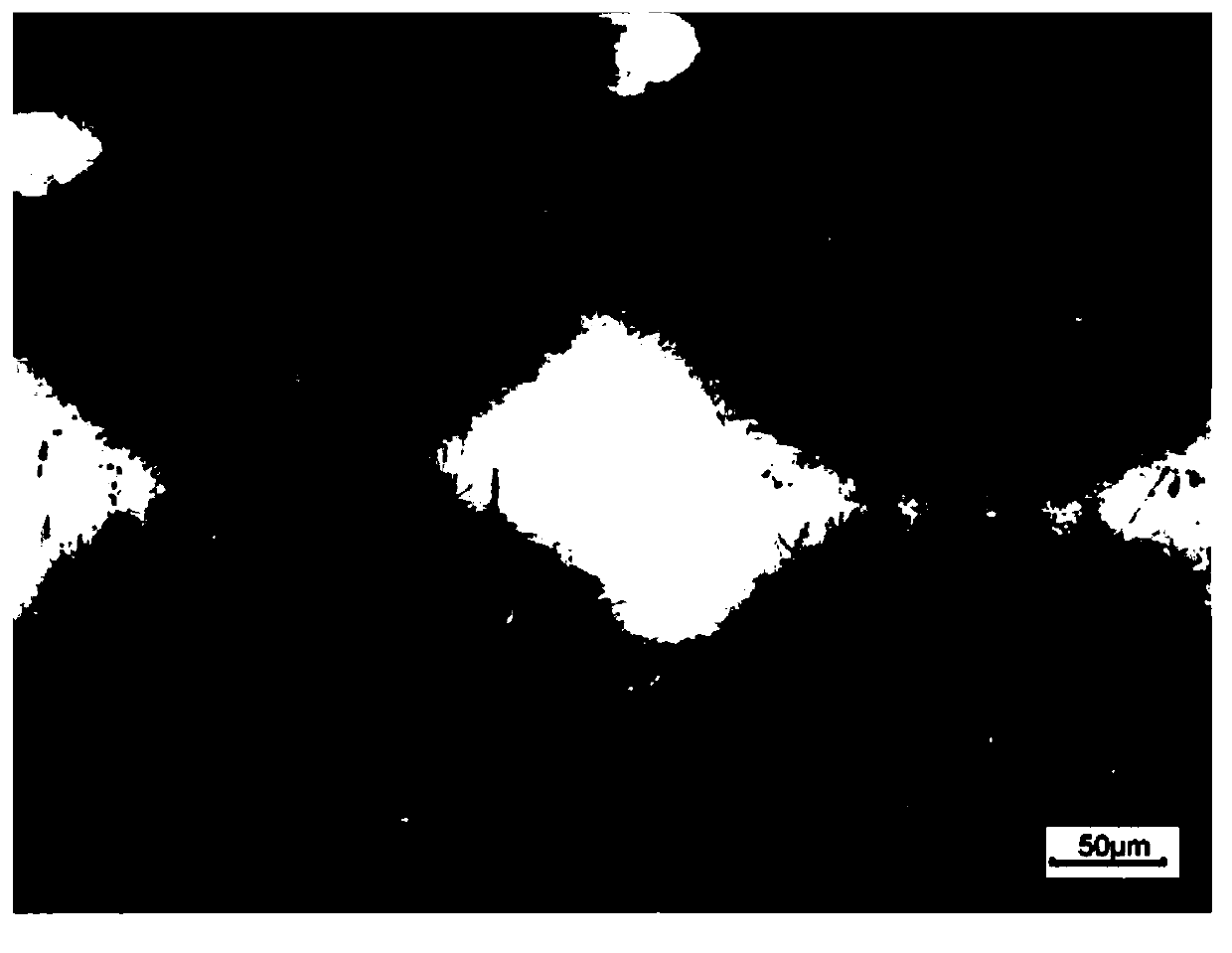

[0057] The PC is used as the processing base material, the silicon material device with the square boss structure is used as the pinpoint indenter, and the template of the nano pit of the Fabry-Perot optical resonant cavity is processed by the pin nanoimprinting method.

[0058] Specifically, the processing substrate is fixed on the workbench, and the imprinting surface of the microstructure mold having the above-mentioned needlepoint indenter is controlled to be in contact with the area to be processed; the heating laser is turned on, and the laser beam is focused and irradiated on the surface of the embossing surface , the focal spot size is 500um, the surface temperature rises through energy radiation, and the surface processing temperature is about 250°C.

[0059] When the surface temperature of the embossed surface reaches the processing temperature of the substrate, the embossing pressure is applied to the embossed surface of the microstructure mold, and the pressure is m...

Embodiment 3

[0063] The PMMA-MA copolymer is used as the processing substrate, and the metal nickel material grating with a line width of 600nm is used as the needle tip indenter, and the needle nanoimprinting method is used to process the holographic pattern template with a specific pattern.

[0064] Specifically, the processing substrate is fixed on the workbench, and the imprinting surface of the microstructure mold having the above-mentioned needlepoint indenter is controlled to be in contact with the area to be processed; the heating laser is turned on, and the laser beam is focused and irradiated on the surface of the embossing surface , the focal spot size is 100um, the surface temperature rises through energy radiation, and the surface processing temperature is about 180°C.

[0065] When the surface temperature of the embossed surface reaches the processing temperature of the substrate, the embossed surface of the microstructure mold is controlled to apply embossing pressure, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com