X ray and laser coaxial system

An X-ray and laser technology, applied in the field of X-ray radiation field measurement system, can solve the problems of difficult to realize the main axis of X-ray beam, unable to realize fast conversion, difficult to realize, etc., and achieve convenient coaxial processing of X-ray and laser. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

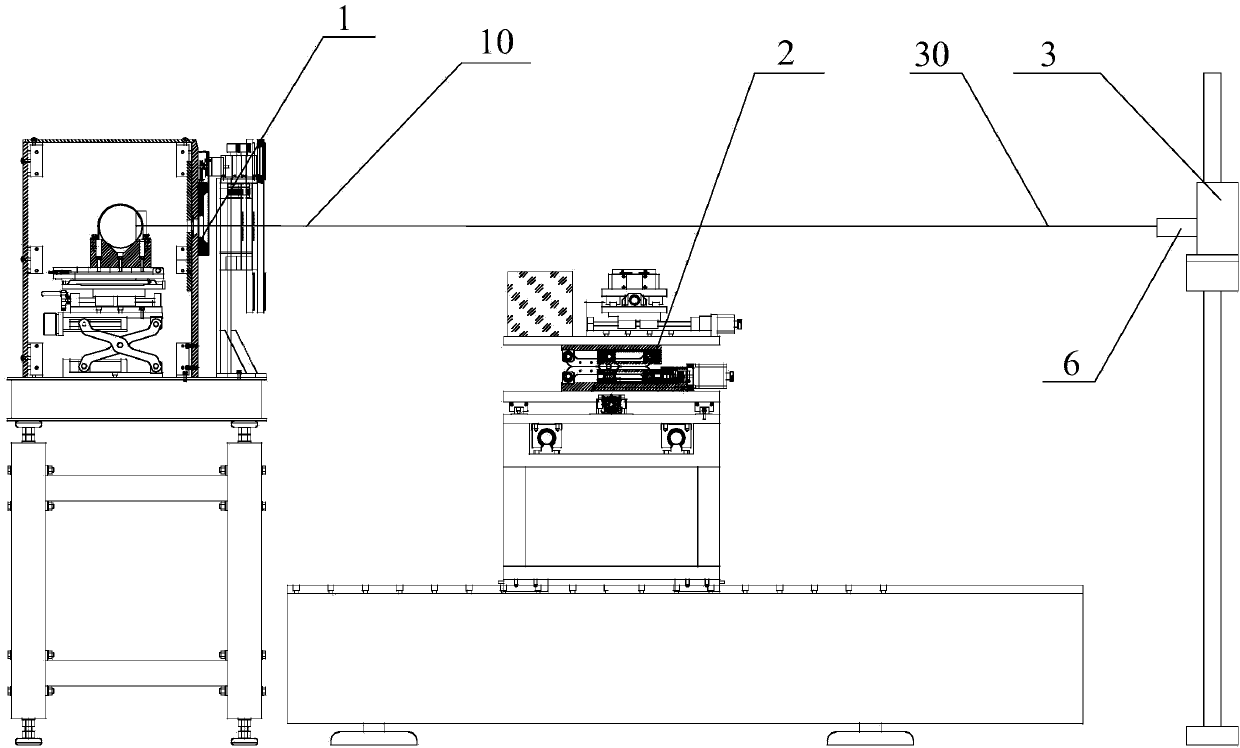

[0044] figure 1 It is a schematic diagram of the X-ray and laser coaxial system of the present invention, as shown in the figure, the present invention includes an ionization chamber adjustment device 2 and a laser adjustment device 3 .

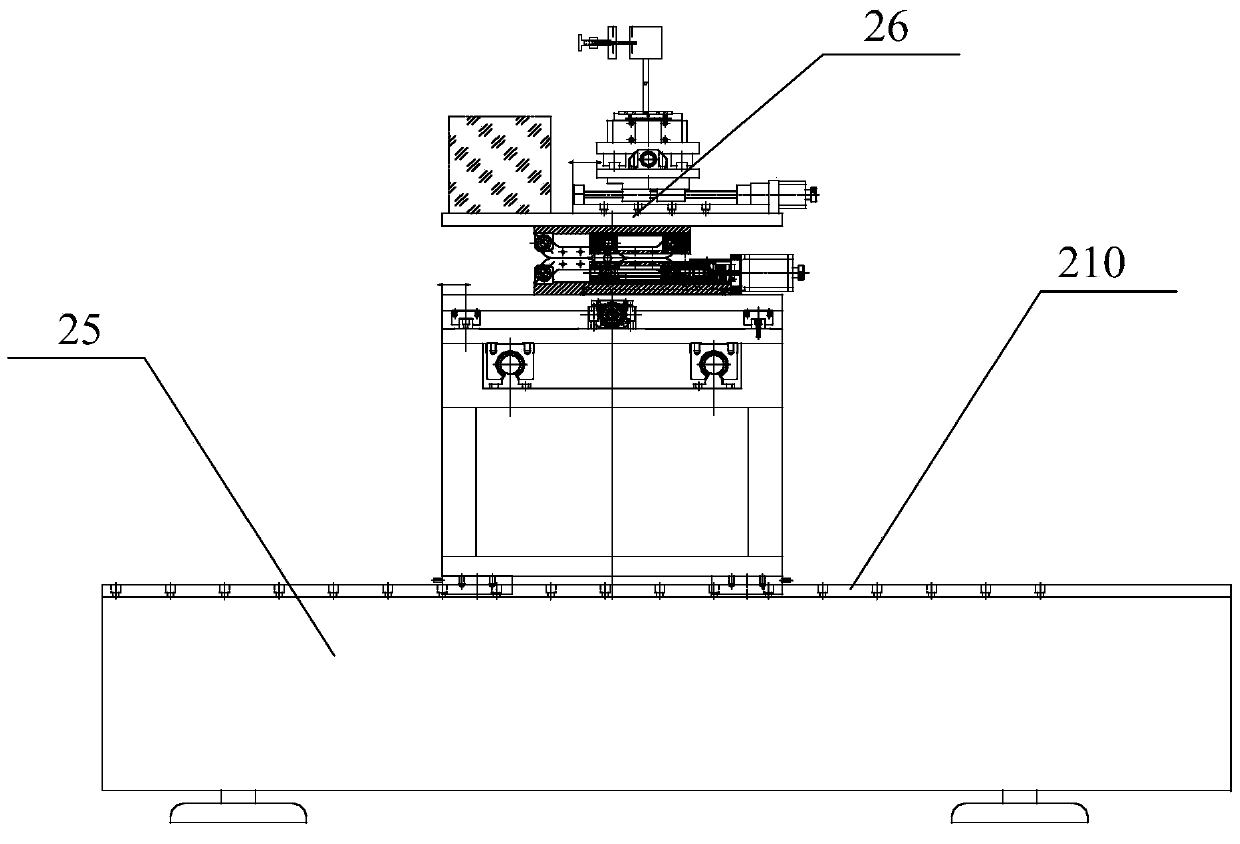

[0045] The ionization chamber adjustment device 2 has a first guide rail 210 for setting up an ionization chamber or an area array flat panel detector. The ionization chamber or area array flat panel detector receives the X-rays 10 emitted from one side of the ionization chamber adjustment device. The first rail 210 It is parallel to the X-ray 10, and the beam center of the X-ray 10 coincides with the center of the area array flat panel detector. Specifically, the X-ray 10 may be emitted from the X-ray tube 9 of the X-ray emitting device 1 .

[0046] The laser adjustment device 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com