SF6 gas leakage detection method base on fractional laser-induced breakdown spectroscopy

A technology of gas leakage and fractional laser, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, material excitation analysis, etc., can solve the problems that cannot be monitored in real time online, and achieve coverage The effect of wide range, improving real-time performance and eliminating misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

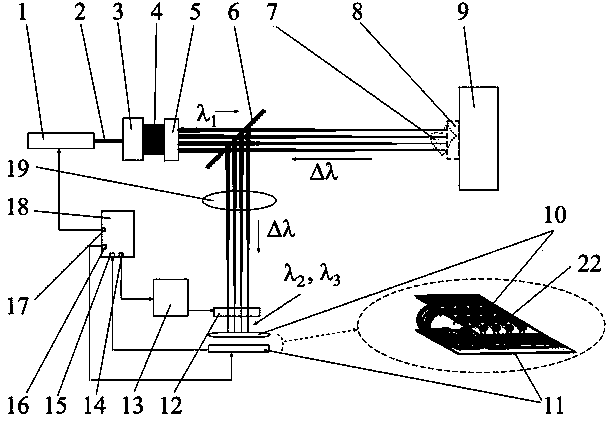

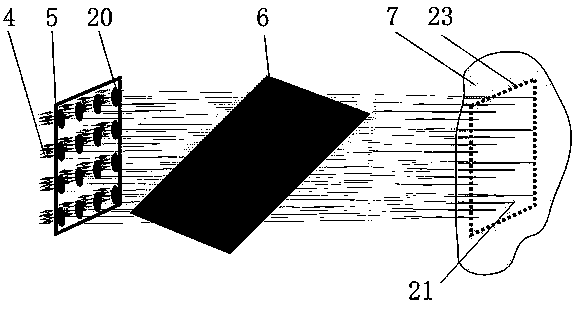

[0022] The specific embodiment of the present invention is as figure 1 with 2 shown.

[0023] SF to be monitored 6 Electric equipment 9 contains SF 6 (sulfur hexafluoride) gas, which plays the role of insulation and arc extinguishing. When SF 6 When electrical equipment 9 is normal, there is no SF 6 gas leak; when SF 6 Power Equipment 9 in SF 6 There are sand holes, cracks or gasket aging in the gas chamber tank and welds, which lead to SF 6 When the gas 7 leaks out, there will be a certain concentration of SF in the monitoring area 8 6 gas.

[0024] This embodiment is carried out like this:

[0025] SF 6 The fractional laser-induced breakdown spectroscopy detection system for gas leakage consists of a host computer 18, a high-energy pulse laser 1, a beam expander 3, a focusing lens array 5, a beam splitter 6, a photodetector array 10, a drive amplification output circuit 11, and an AOTF Filter 12, AOTF drive controller 13, and lens 19 are composed. The focusing l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com