Method for analog computation and detection of road test fuel consumption of vehicle in multiple working conditions

A technology of analog calculation and detection method, which is applied in the direction of measuring device, relative volume flow measurement, liquid/fluid solid measurement, etc., and can solve problems such as large error, calculation of torque ratio, and high cost of vehicle running-in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

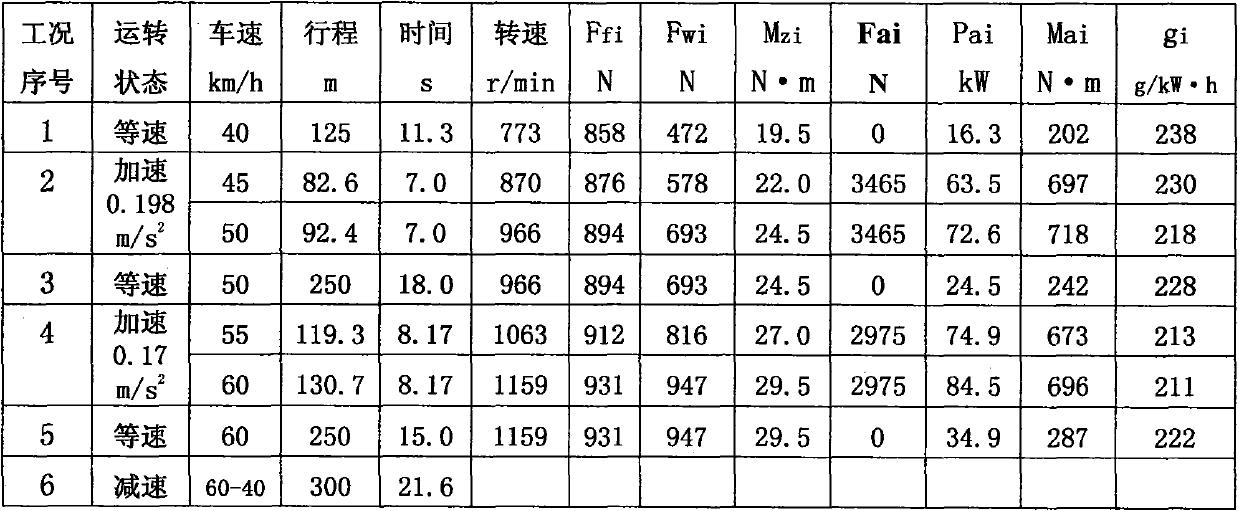

[0026] According to GB / T12545.2-2001 "Commercial Vehicle Fuel Consumption Test Method" six working conditions cycle, with a 11-meter-long new bus model to calculate the full load six working conditions cycle road test fuel consumption is For example, to describe the specific implementation.

[0027] 1. Vehicle-related technical parameters: curb weight 11,500kg, total mass 15,500kg, engine rated power / rotation speed 177kW / 2300r / min, fuel is diesel, confirm the six-gear test, the sixth-gear transmission ratio i g is 0.740, the single-stage main transmission ratio is 4.875, the tire type is 11.00R22.5, the tire type is a radial tire with a section width greater than 8.25in, the body length×width×height is 11270mm×2490mm×3520mm, and the front wheelbase is 2020mm. Fuel consumption of road test with full load and multiple working conditions.

[0028] 2. Determine each speed point V i : In the acceleration condition, the vehicle speed interval is divided into 5km / h, and the calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com