Protecting device for flue gas ducts of electric arc furnace

A protection device, electric arc furnace technology, applied in the field of electric arc furnace flue gas flue, can solve the problems of consuming industrial water, wasting heat, affecting the safe production of electric furnaces, etc., achieving small thermal conductivity, reducing heat loss of flue gas, and improving waste heat recovery. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

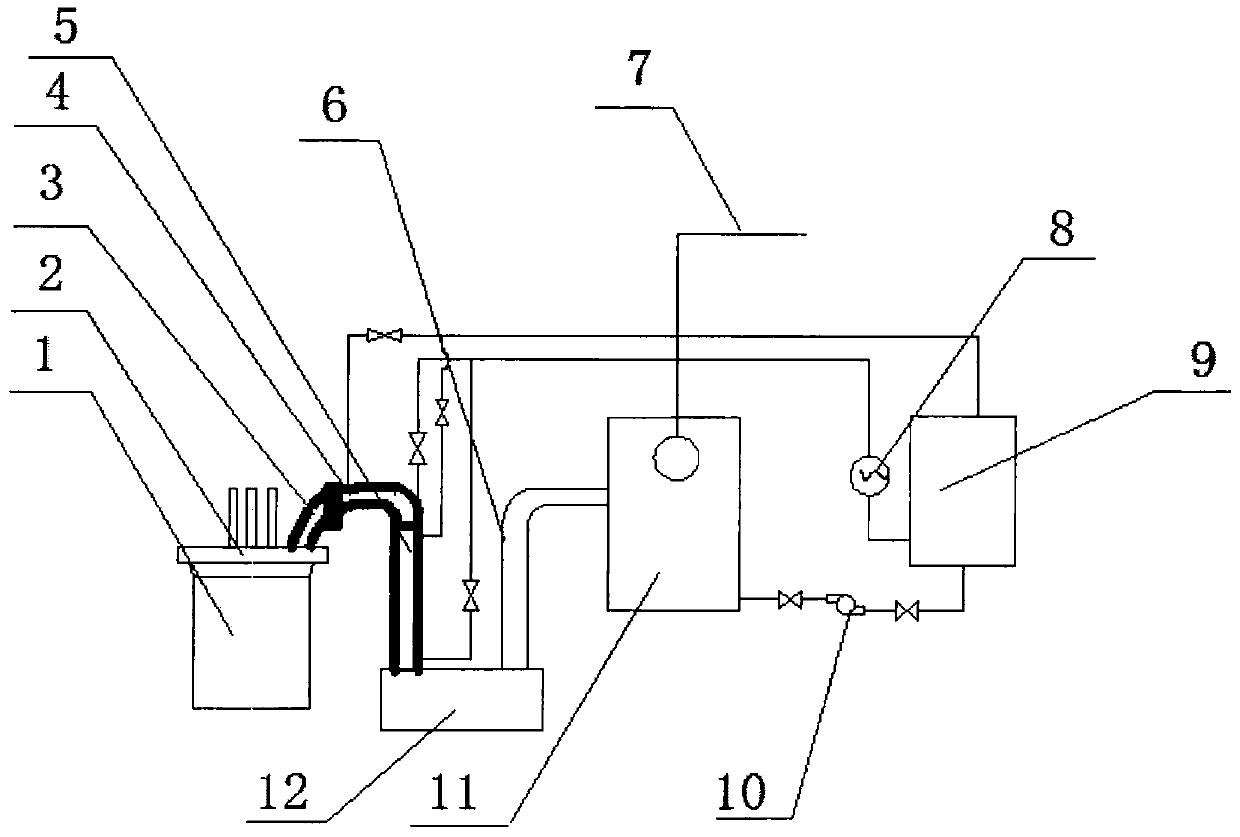

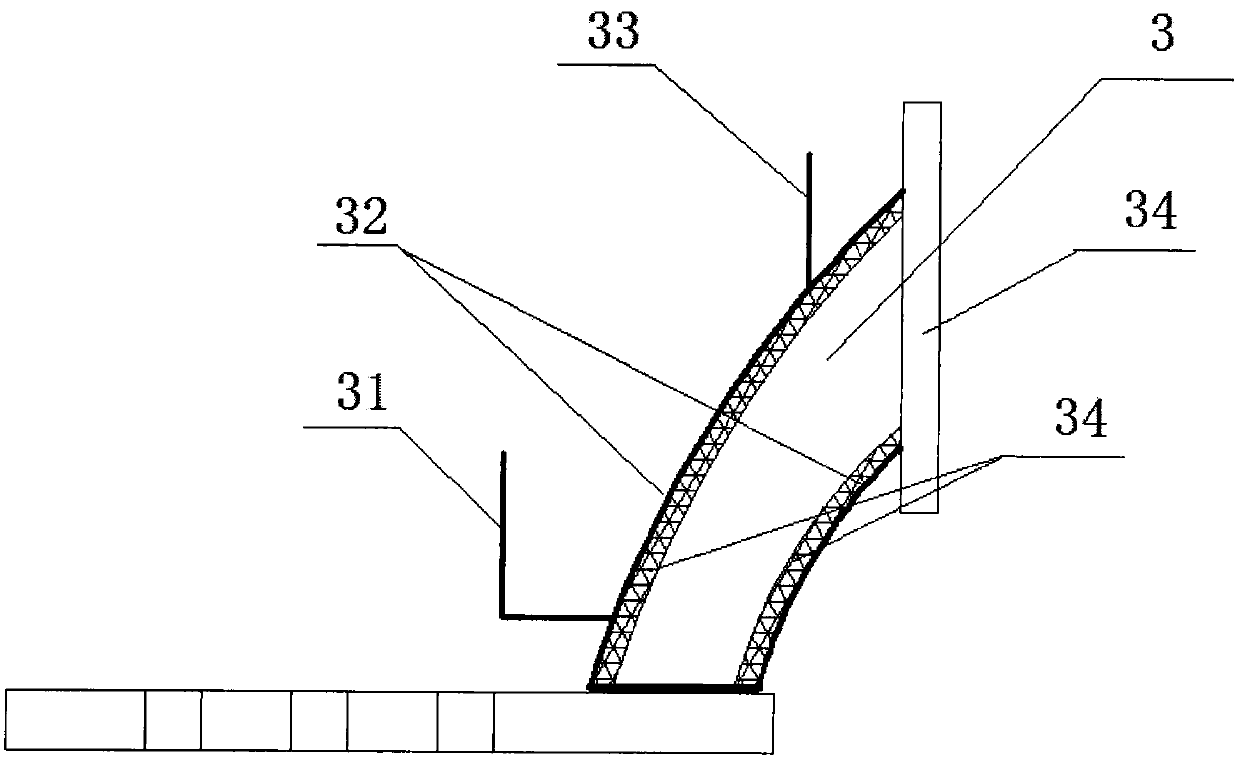

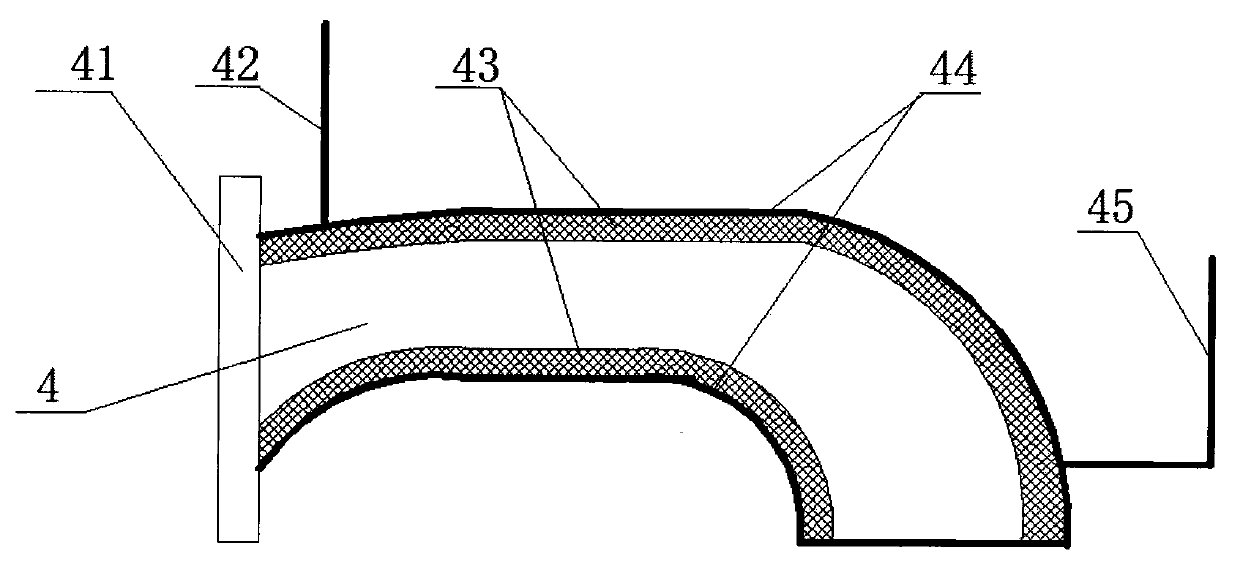

[0026] Such as figure 1 Shown: a protection device for the flue gas flue of an electric arc furnace, including the furnace cover (2) of the electric arc furnace (1), the water-cooled flue (3) of the electric arc furnace cover, the mobile water-cooled flue (4), and the fixed flue (5) and combustion settling chamber (10). Such as figure 2 , image 3 , Figure 4 Shown: Stainless steel nails are installed on the inside of the water-cooled flue (3), the mobile water-cooled flue (4) and the fixed flue (5) of the furnace cover, that is, on the wall of the water-cooled steel pipe on the side contacting the high-temperature flue gas. Install the stainless steel bars on the nails, and then pour the brown corundum castable. The thickness of the castable is controlled at 5-8mm. After pouring is completed, dry naturally for one week, and then use forced drying for one week according to the requirements of castables. The temperature rise of the flue gas in forced drying should not exce...

Embodiment 2

[0029] Such as figure 1 Shown: a protection device for the flue gas flue of an electric arc furnace, including the furnace cover (2) of the electric arc furnace (1), the water-cooled flue (3) of the electric arc furnace cover, the mobile water-cooled flue (4), and the fixed flue (5) and combustion settling chamber (10). Such as figure 2 , image 3 , Figure 4 Shown: Stainless steel nails are installed on the inside of the water-cooled flue (3), the mobile water-cooled flue (4) and the fixed flue (5) of the furnace cover, that is, on the wall of the water-cooled steel pipe on the side contacting the high-temperature flue gas. Install stainless steel bars on the nails, and then pour mullite castables. The thickness of the castables is controlled at 8-10 mm. After pouring is completed, dry naturally for one week, and then use forced drying for one week according to the requirements of castables. The temperature rise of the flue gas in forced drying should not exceed 5°C / hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com