Fluidized bed boiler combustion optimization adjustment control method and device

A fluidized bed boiler and combustion optimization technology, which is applied to fluidized bed combustion equipment, combustion methods, and fuel burned in a molten state, etc. It can reduce the influence of artificial control factors, improve the combustion efficiency and the utilization rate of coal resources, and achieve the effect of accurate and timely control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

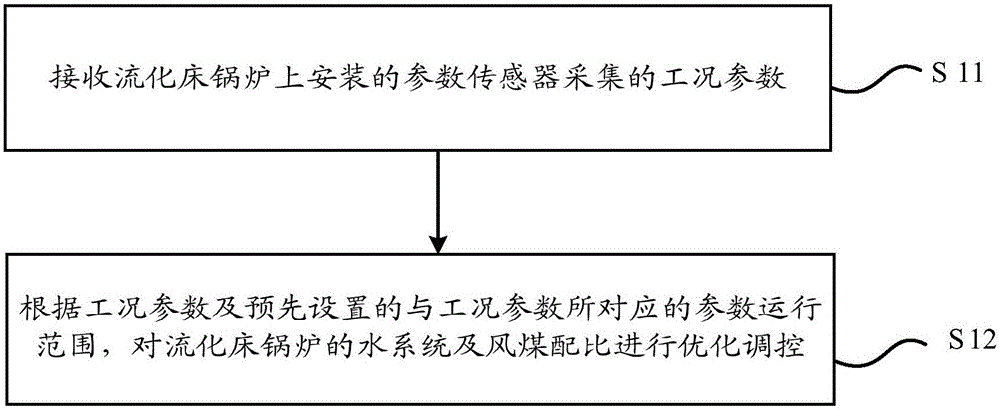

[0026] The embodiment of the present invention provides a fluidized bed boiler combustion optimization adjustment control method, such as figure 1 As shown, the main processing steps include:

[0027] Step S11: receiving the working condition parameters collected by the parameter sensor installed on the fluidized bed boiler;

[0028] Step S12: According to the operating condition parameters and the pre-set parameter operating range corresponding to the operating condition parameters, optimize and control the water system and the air-to-coal ratio of the fluidized bed boiler;

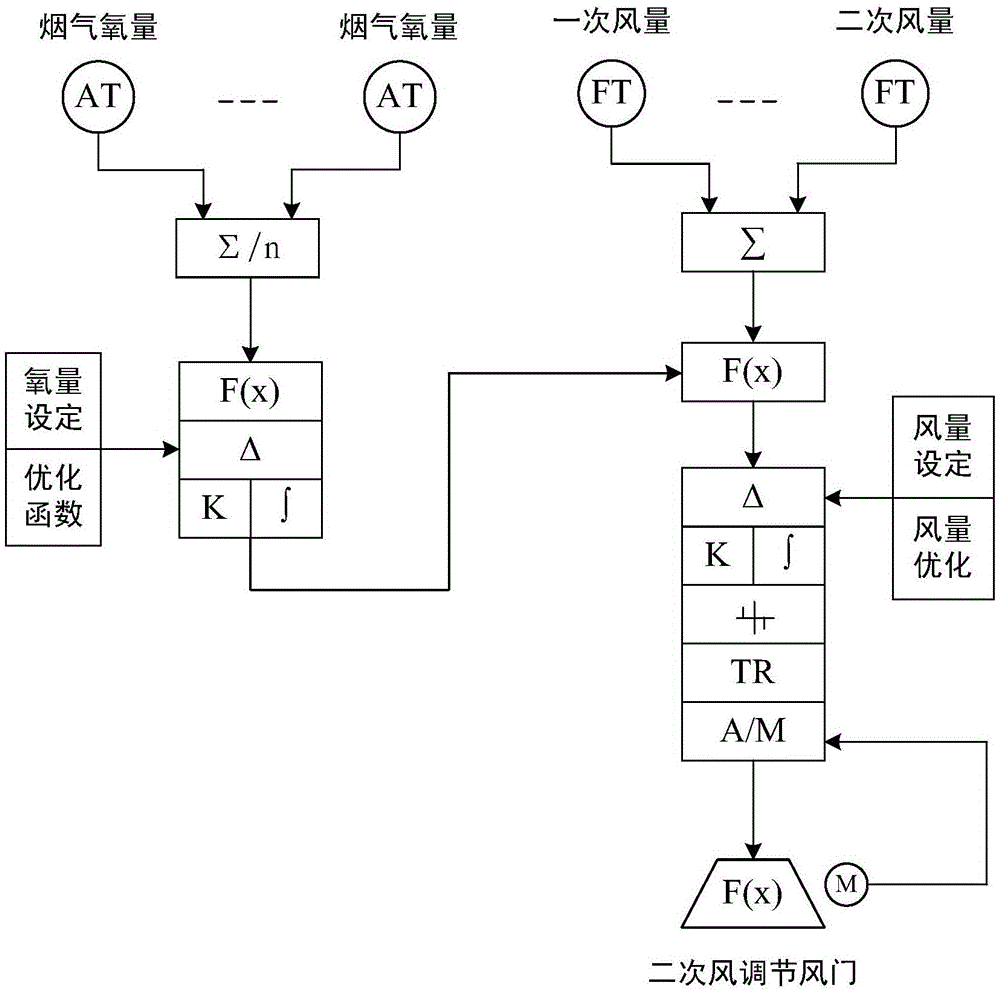

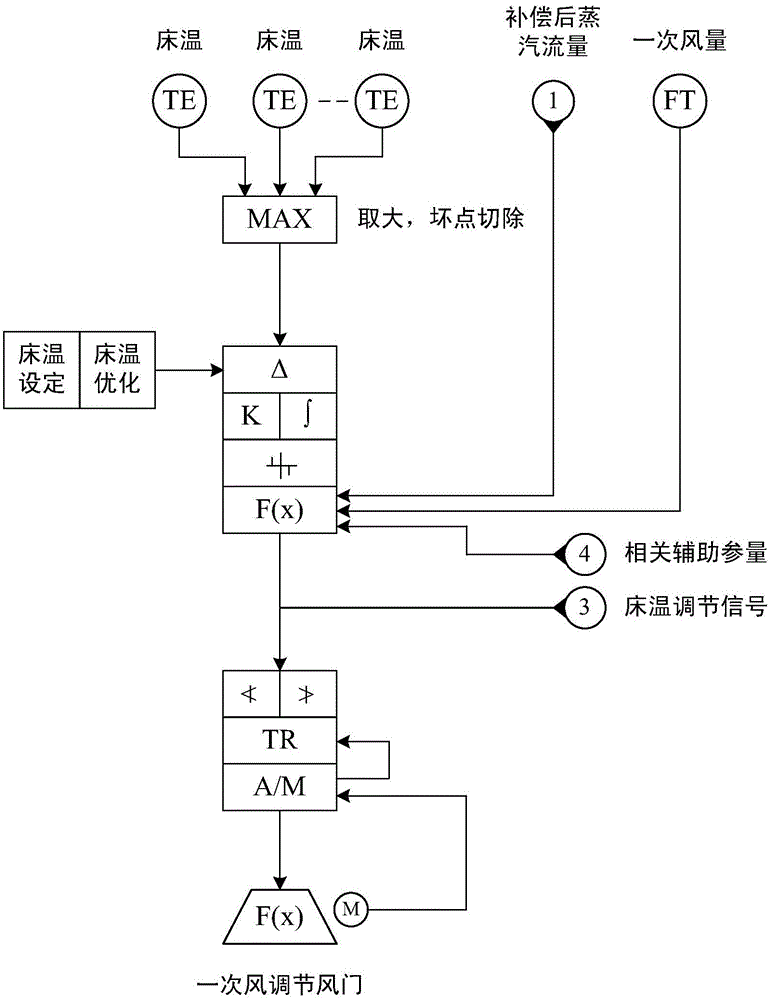

[0029] Among them, the water system regulation of the fluidized bed boiler includes: automatic regulation of the drum water level, automatic regulation of the main steam temperature; the optimization regulation of the air-coal ratio of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com