A lng gasification pressure regulating metering skid and its operation method

An operation method and a technology of metering skids, which are applied to container filling methods, container discharge methods, pressure vessels, etc., can solve the problems of short service life, high maintenance cost, low work efficiency, etc., and achieve improved service life, convenient operation, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

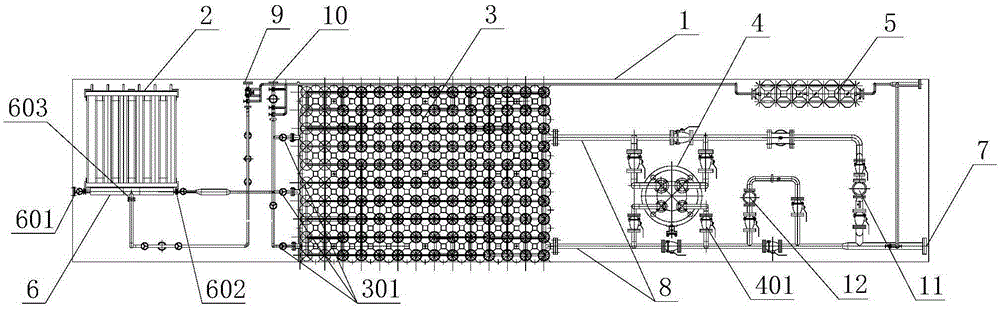

[0037] Such as figure 1As shown, a LNG gasification and pressure regulating metering skid provided in this embodiment includes a base 1, and the base 1 is horizontally provided with an unloading supercharger 2, an air-temperature gasifier 3, an electric heating 4 and the air-temperature EAG heater 5; a first main pipe 6 is horizontally provided on one side of the unloading supercharger 2, and a first inlet 601 and a first air outlet 602 located at both ends thereof are opened on the first main pipe 6, and The second gas outlet 603 in the middle; the side of the air-temperature vaporizer 3 near the unloading supercharger 2 is provided with three liquid inlets, the second gas outlet 603 extends two gas outlet branches through the pipeline, the first The gas outlet branches are connected to the first to third liquid inlets of the air-temperature vaporizer 3 respectively, and the second gas outlet branch is connected to the natural gas outlet 7 through the air-temperature EAG heat...

Embodiment 2

[0040] The structure of the device in this embodiment is the same as that of Embodiment 1, and the operation method of the LNG gasification pressure regulating metering skid of this embodiment is carried out according to the following steps:

[0041] Step (1): When using for the first time, ensure that the base 1 is fixed on a horizontal surface, first use inert gas nitrogen to purge the pipeline at a pressure of 1Mpa to discharge debris, keep it for 30 minutes, and use a white-painted wooden target plate on all gas outlets Stop for 5 minutes, if there is no foreign matter, it is qualified, otherwise continue to blow until no foreign matter flies out of all outlets;

[0042] Step (2): Connect the liquid inlet valve on the tank car to the first inlet 601, open the valve of the unloading supercharger 2 at an opening of 2% / s to pre-cool the pipeline for 9 minutes, and then pressurize the pipeline with the unloading Device 2 increases the tank car to 0.7Mpa, opens the liquid inlet...

Embodiment 3

[0045] The structure of the device in this embodiment is the same as that of Embodiment 1, and the operation method of the LNG gasification pressure regulating metering skid of this embodiment is carried out according to the following steps:

[0046] Step (1): When using for the first time, ensure that the base 1 is fixed on a horizontal surface, first use inert gas nitrogen to purge the pipeline at a pressure of 2Mpa to discharge debris, keep it for 35min, and use a white-painted wooden target plate at all gas outlets Stop for 5 minutes, if there is no foreign matter, it is qualified, otherwise continue to blow until no foreign matter flies out of all outlets;

[0047] Step (2): Connect the liquid inlet valve on the tank car to the first inlet 601, open the valve of the unloading booster 2 at an opening of 1% / s to pre-cool the pipeline for 8 minutes, and then pressurize the pipeline with the unloading Device 2 increases the tank car to 0.8Mpa, opens the liquid inlet valve on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com