Production process of equal-proportion stretching and retracting expansion tube

A production process and expansion tube technology, which is applied in the production process field of proportional telescopic expansion tubes, can solve the problems of inconvenient connection between water pipes and water sources and nozzles, short service life of water pipes, and difficult folding and storage, so as to facilitate storage and arrangement, extend Long life, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

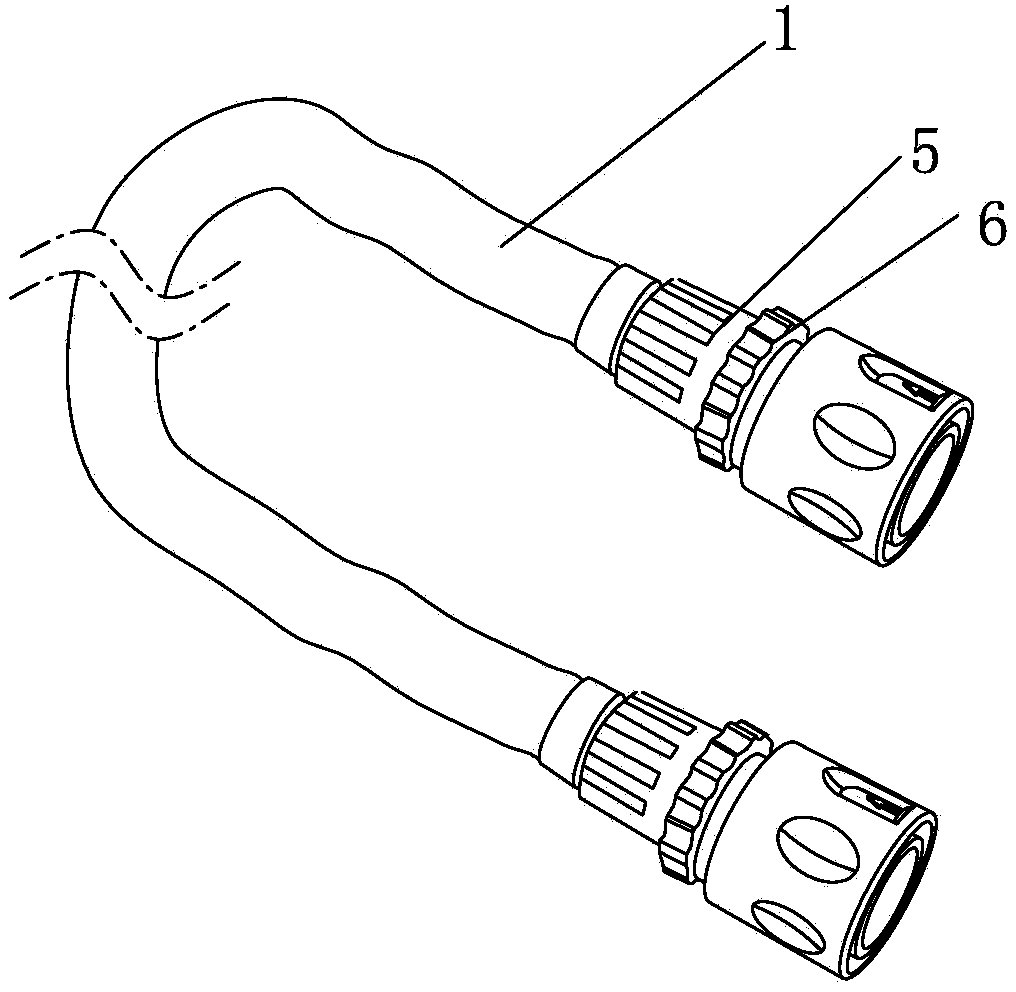

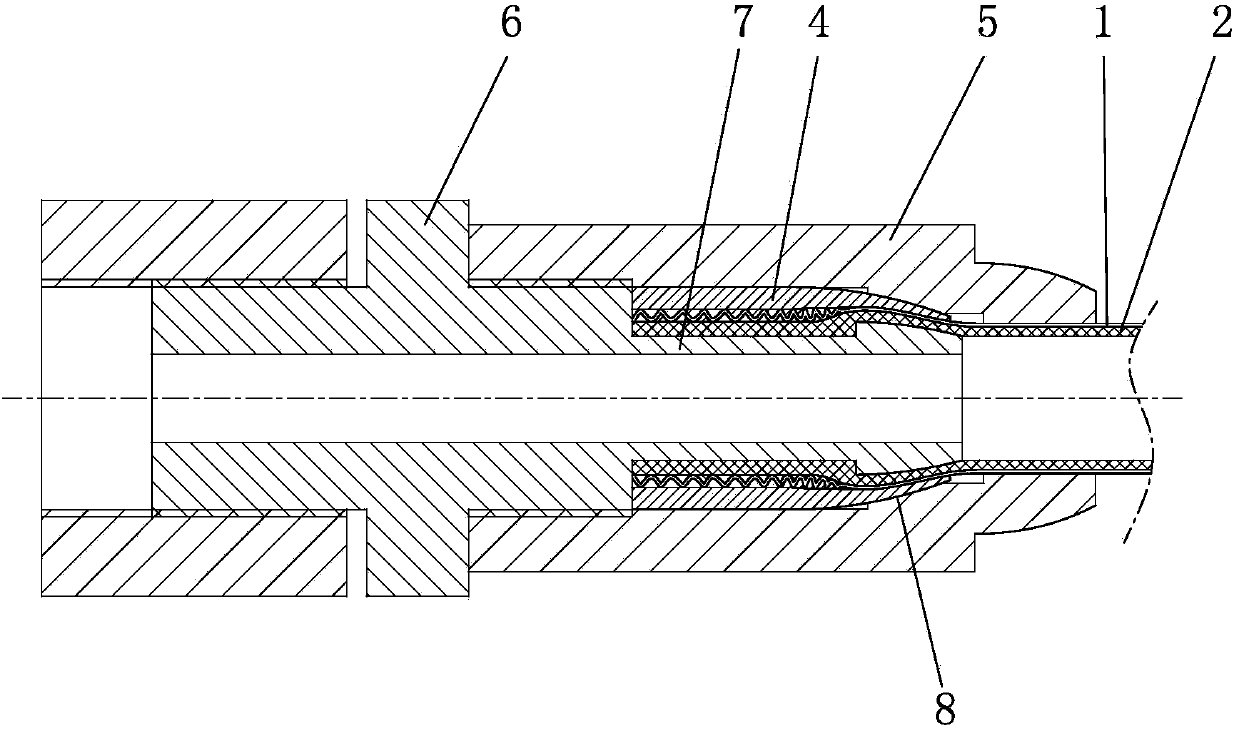

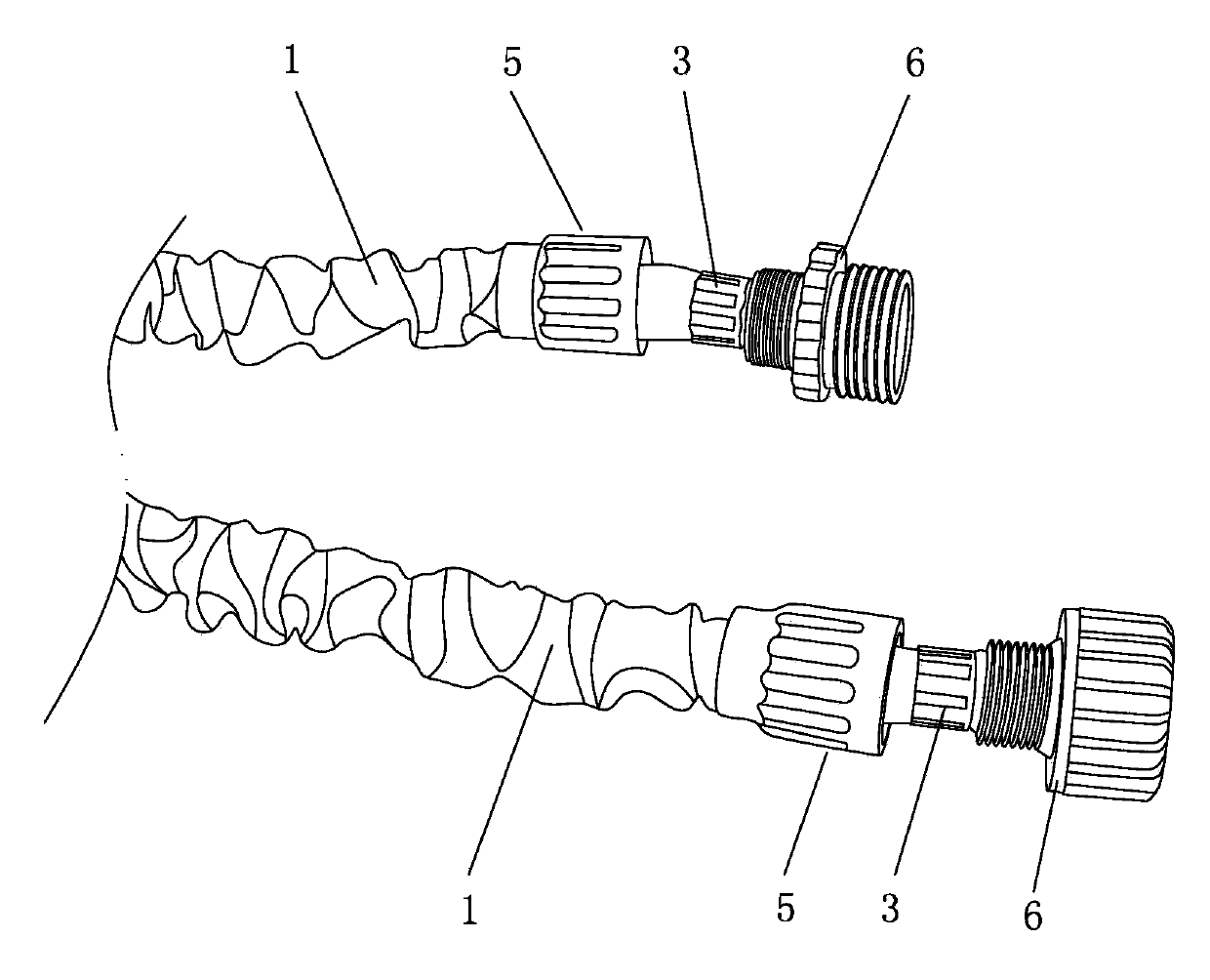

[0024] The invention will be further described below in conjunction with the accompanying drawings with specific embodiments, see figure 1 —3:

[0025] A kind of production technology of equal-proportion telescopic expansion tube, concrete steps are as follows:

[0026] 1) Set the elastic fabric tube 1 outside the inner tube 2. The inner tube can be stretched axially and expanded radially. The elastic fabric tube is a two-way elastic fabric in warp and weft. The elastic fabric tube is woven with spandex-coated yarn and polyester The tubular fabric formed, spandex covered yarn adopts 75% spandex high elastic yarn 42D and 25% polyester network yarn 75D, spandex high elastic yarn is polyurethane fiber, and polyurethane fiber is made of PTMEG (polytetramethylene Ether diol) and MDI (diphenylmethane diisocyanate) polymerized;

[0027] 2) Set the metal sleeve 3 or the claw 4 and the locking sleeve 5 on both ends of the elastic cloth pipe 1;

[0028] 3) inserting the two ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com