Water cooling oil-free spindle nose sealing structure for horizontal type concrete stirrer

A technology of concrete mixer and sealing structure, which is applied in the direction of engine sealing, cement mixing device, mechanical equipment, etc., to achieve the effect of ensuring quality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

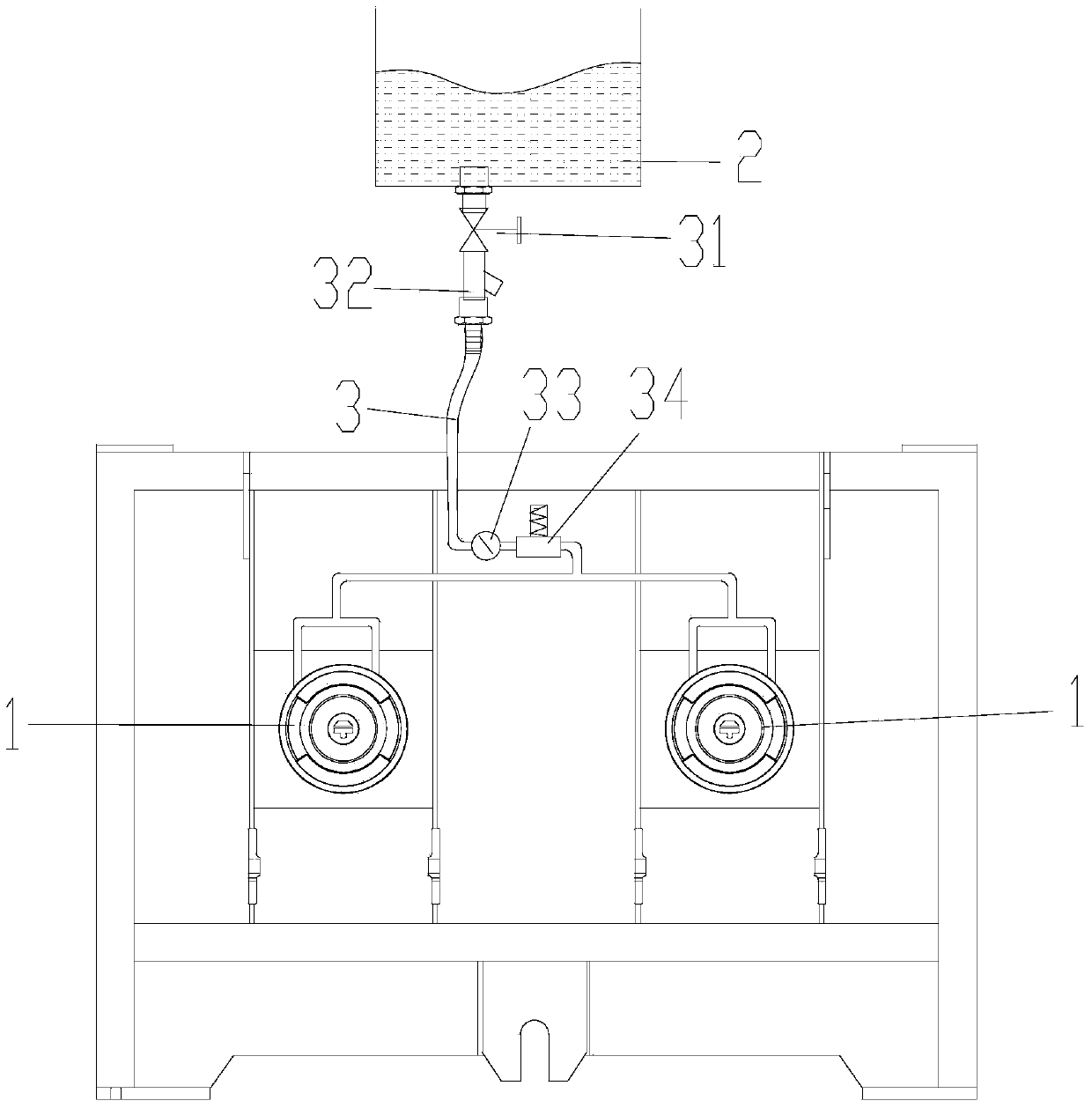

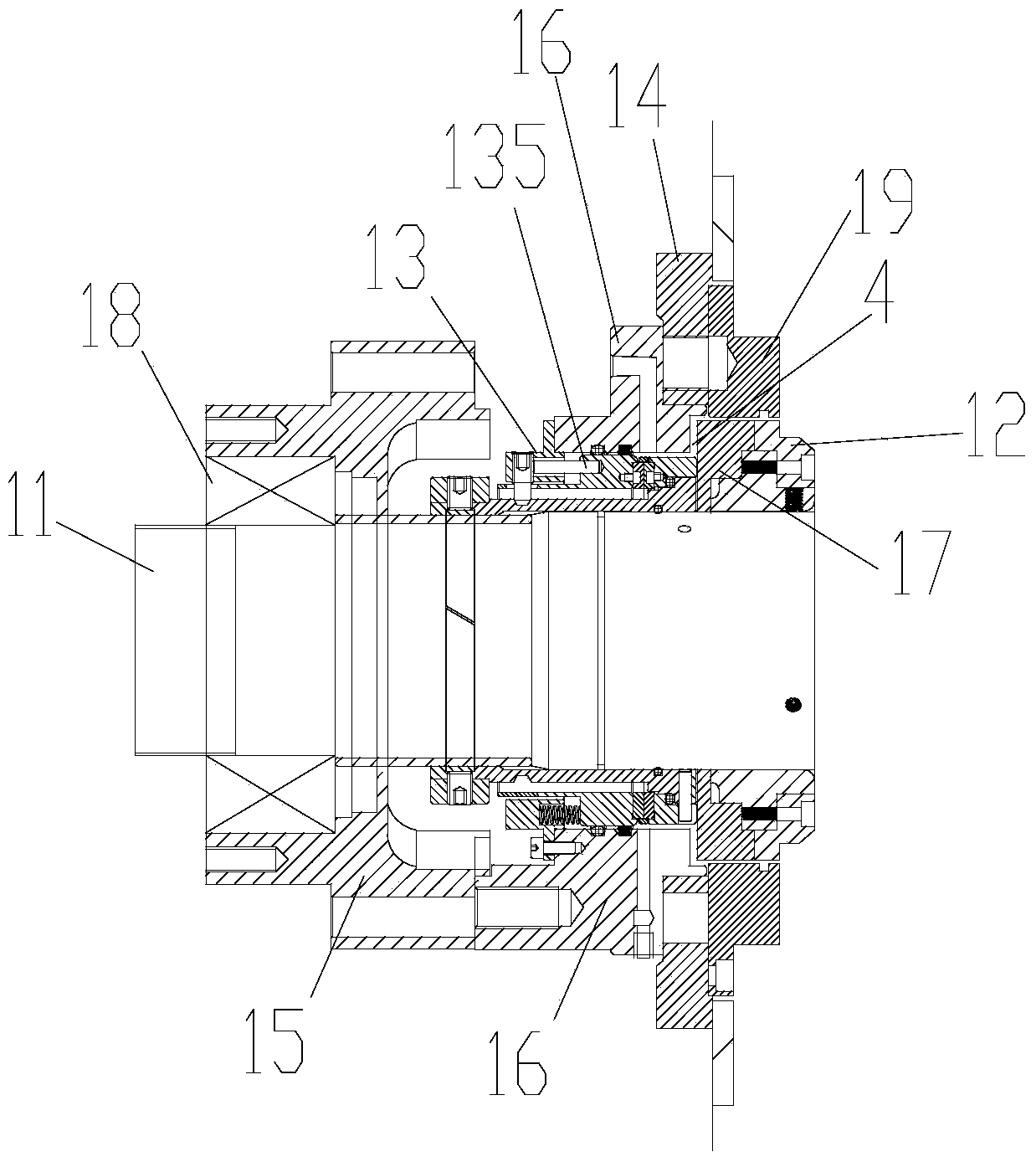

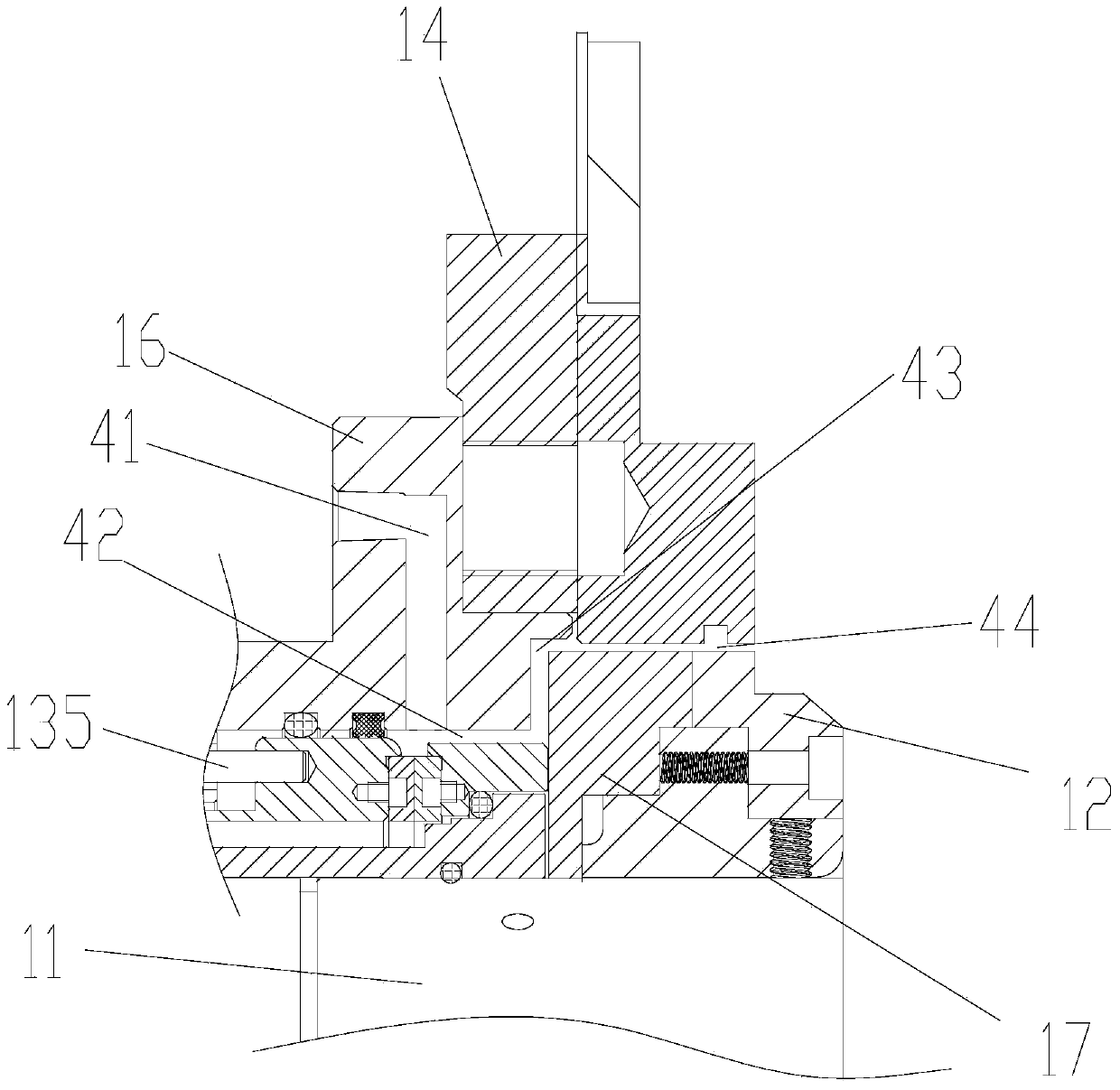

[0020] Such as figure 1 , 2 A water-cooled oil-free shaft head seal structure for a horizontal concrete mixer is shown, including at least one oil-free shaft head 1 installed on the horizontal concrete mixer, a water supply device 2, a water control pipeline 3 and an oil-free shaft head installed on the horizontal concrete mixer. The annular water-cooling channel 4 on the oil shaft head 1;

[0021] The oil-free shaft head 1 includes a rotating shaft 11 extending into the mixing chamber, a rotating protection ring 12 arranged on the rotating shaft 11, a sealing assembly 13 arranged at the front end of the rotating protecting ring 12, and a reinforcing plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com