A cabin integrated electro-hydraulic servo mechanism

An electro-hydraulic servo and electro-hydraulic servo valve technology, applied in servo motors, servo motor components, mechanical equipment, etc., can solve the problems of inability to meet the requirements of use, high processing accuracy requirements, sensitive to oil pollution, etc., to achieve easy installation and The effect of post-maintenance, ensuring reliability and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

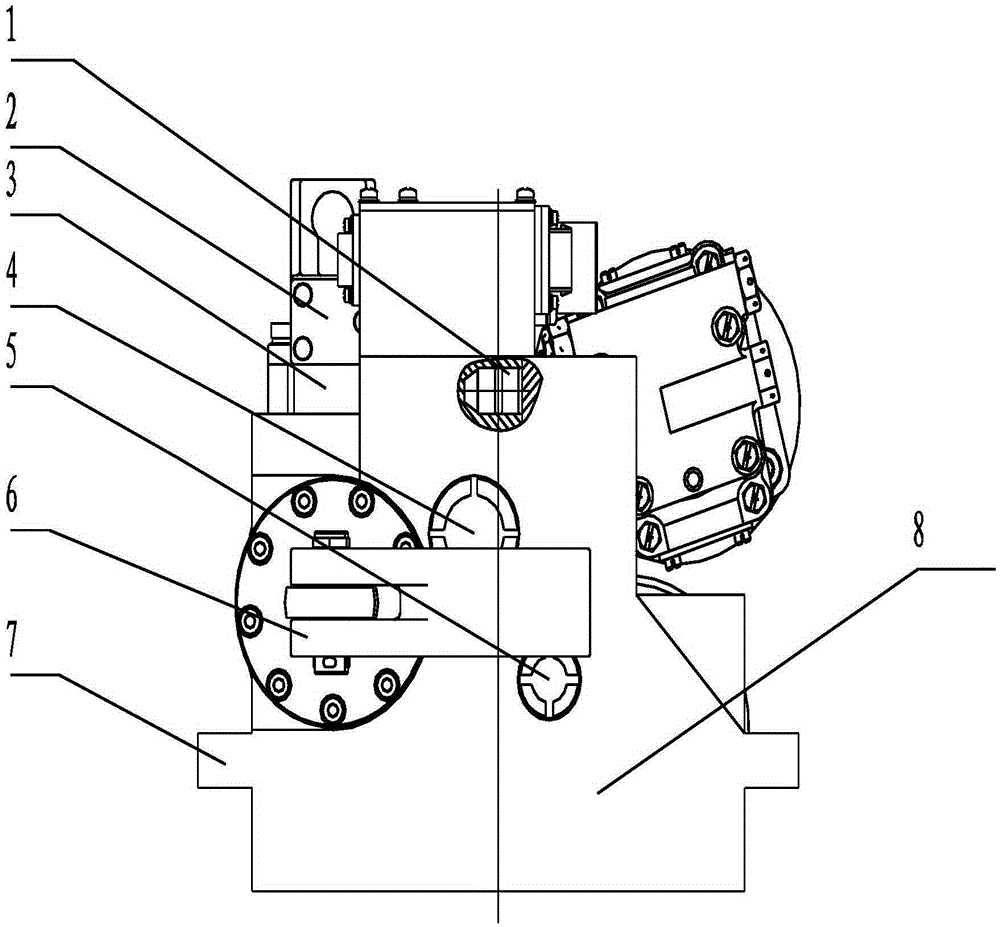

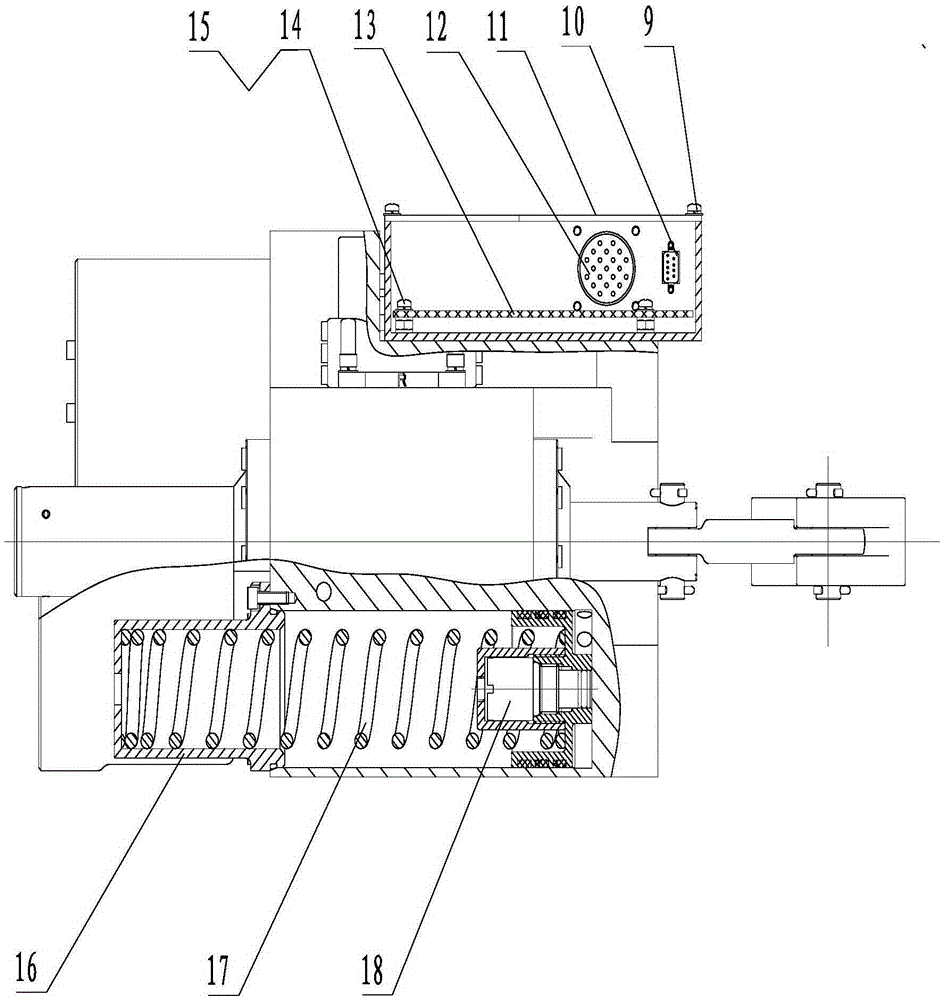

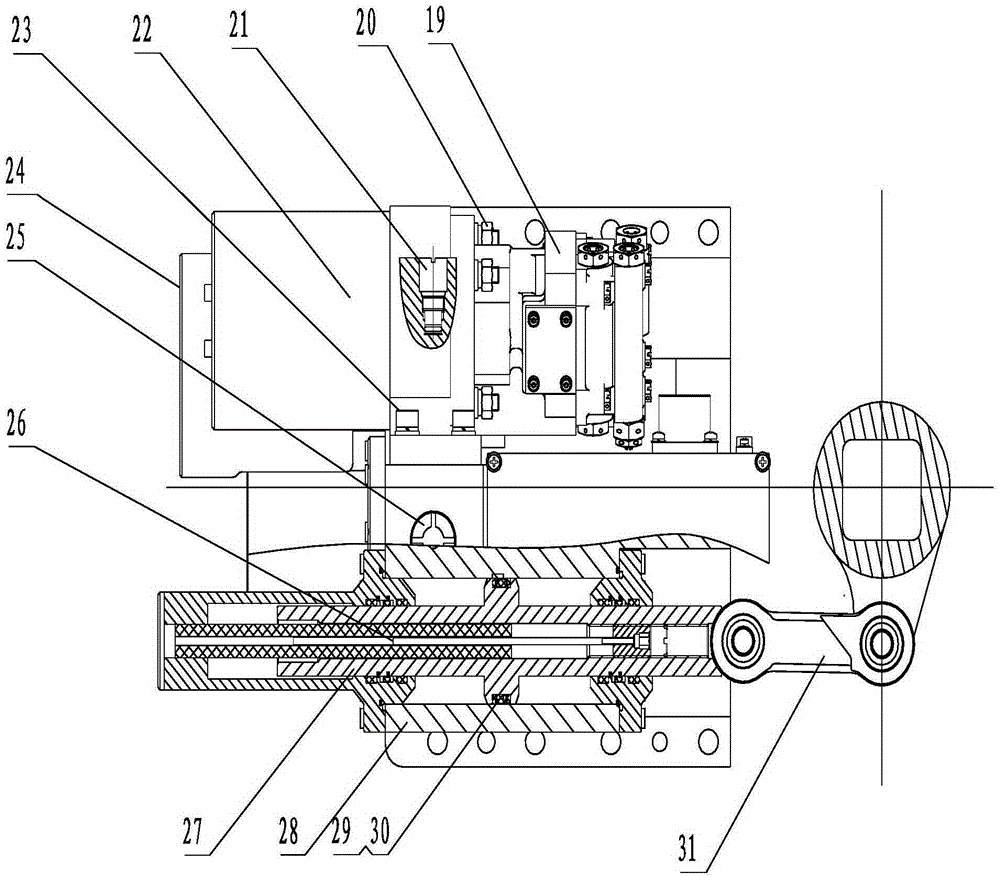

[0031] figure 1 , figure 2 and image 3 It is a structural schematic diagram of the cabin-integrated electro-hydraulic servo mechanism according to the present invention. It mainly includes motor pump combination, hydraulic components, mechanical transmission mechanism, control mechanism and other four parts, which are integrated and installed on the body 7. At the same time, the output shaft of the mechanism is integrated with the rudder shaft connected to the cabin, adopting an integrated design , so the overall device has the advantages of compact structure, small volume, light weight, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com