Efficient processing method for fine yakwool yarn for worsted products

A processing method, the technology of yak cashmere, which is applied in the direction of textiles, papermaking, yarn, etc., can solve the problems that the yarn fineness is not high enough, and it is difficult to achieve high count, so as to increase the drafting ratio, save the roving process, and improve the utilization rate. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

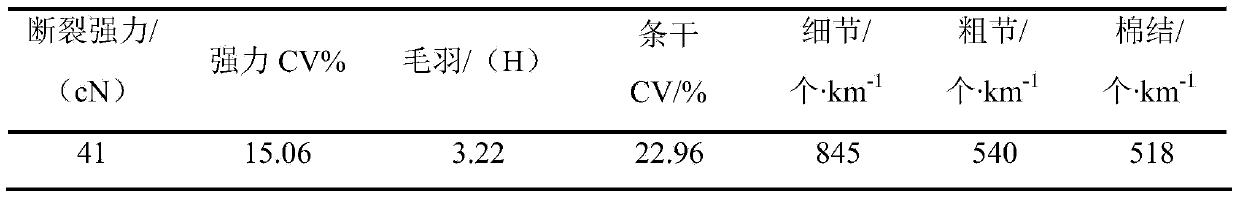

Embodiment 1

[0037] The high-efficiency processing method of the high-count yak cashmere yarn for the worsted product of the present embodiment includes:

[0038] The first step is to pretreat the yak cashmere fiber raw material, which includes: picking and removing foreign fibers.

[0039] Due to the large difference in length and thickness of yak down fiber, it is first necessary to sort the raw materials and pick out the foreign fibers.

[0040] In the second step, the yak wool fiber obtained in the first step is sprayed with hair oil, antistatic agent, yarn reinforcing agent and water layer by layer, while controlling the moisture regain within a preset range and balancing the preset time. To increase the lubrication between fibers, reduce static electricity, reduce the directional friction effect of fibers, and increase the cohesion between fibers.

[0041] Specifically: based on the weight of the yak cashmere fiber obtained in the first step, add 0.6% FX-906 type and crude oil, 0.45...

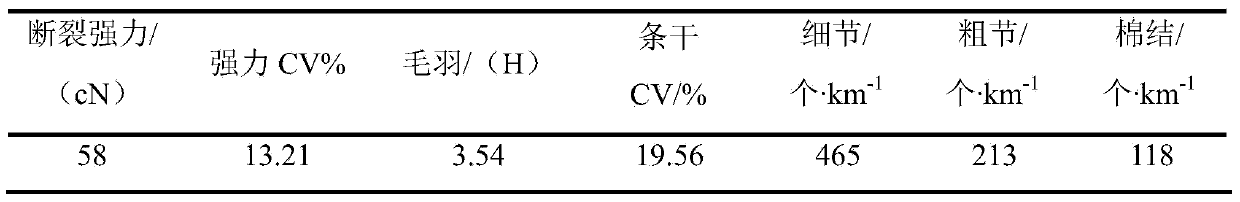

Embodiment 2

[0062] The high-efficiency processing method of high-count yak cashmere yarn for worsted products of the present embodiment, the basic steps are the same as in Example 1, and the specific parameters of each step are different, as follows:

[0063] (1) In the second step, based on the weight of the yak wool fiber obtained in the first step, add 0.8% FX-906 type and crude oil, 0.50% FX-AS20 antistatic agent, 0.48% FX - VSI type yarn strengthening agent and 10% water, control moisture regain at 24%, balance for 24h.

[0064] (2) In the third step:

[0065] In the carding process, the process parameters are: feeding roller speed 4.2r / min, cylinder speed 270r / min, doffer speed 20r / min, sliver weight 9.0g / m.

[0066] In the first pre-drawing process, the process parameters are: the number of pre-drawings is 6, the draft ratio in the rear area is 1.12; the center distance of the front rollers is 45mm, the center distance of the middle rollers is 45mm, and the rear rollers The cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com