A negative pressure compact siro spinning machine

A negative pressure and compact technology, which is applied in the field of compact spinning machines and negative pressure compact Siro spinning machines, can solve the inconvenience of cleaning the hairiness and broken ends of the waste cotton collection box, the production line cannot continue to work, and the production capacity drops and other problems, to achieve the effect of saving equipment update cost, low cost, and small negative pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

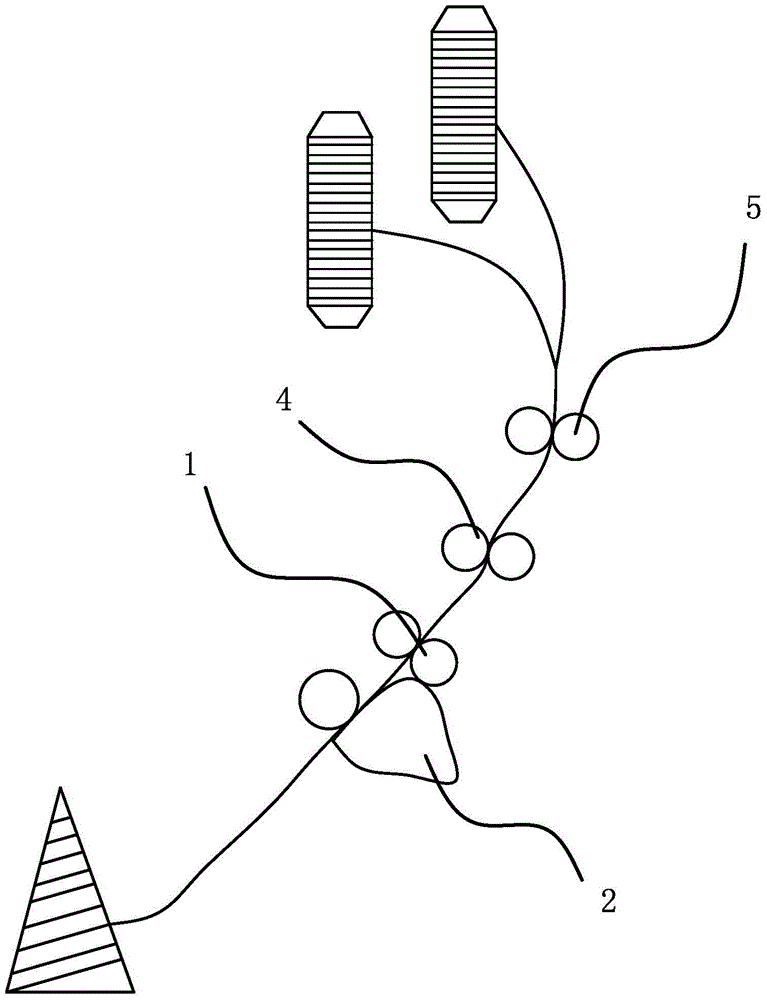

[0034] Such as figure 1 , Figure 4 As shown, the negative pressure compact siro spinning machine includes a frame on which a front roller device 1, a middle roller device 4, a rear roller device 5, a yarn guide hook, a special-shaped tube device 2 and an air suction device 3 are arranged.

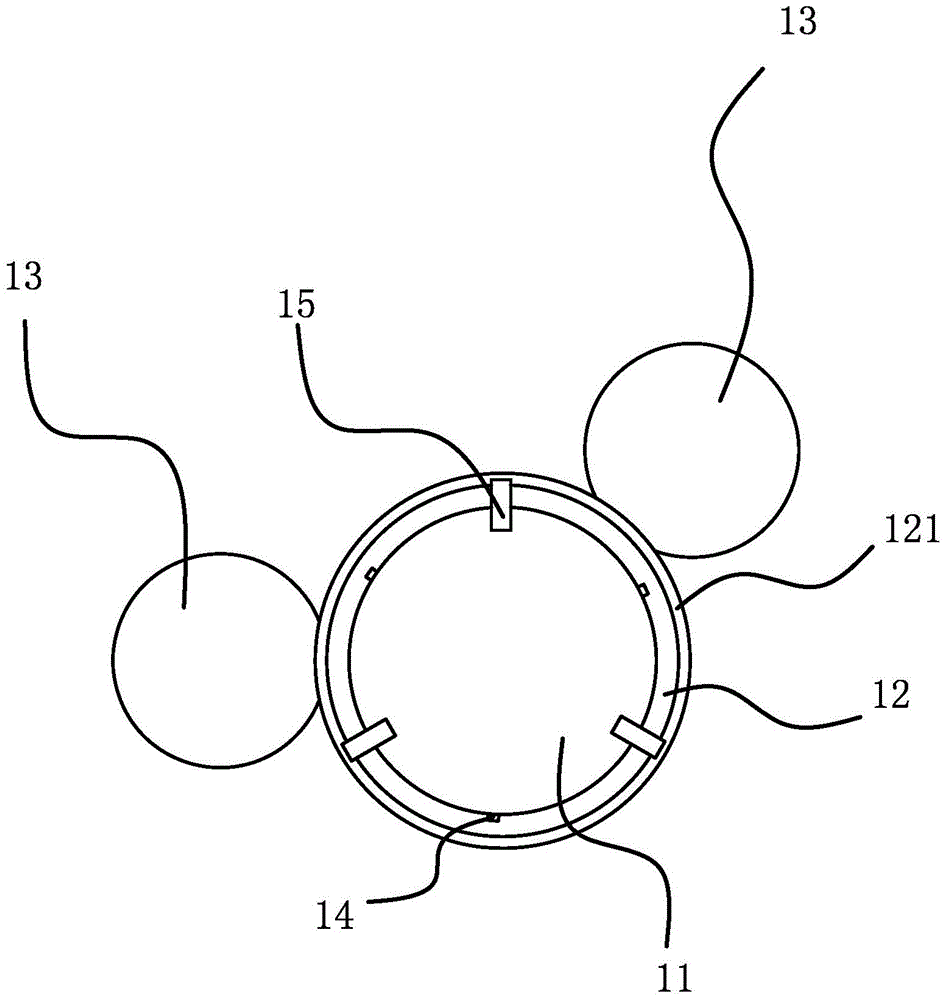

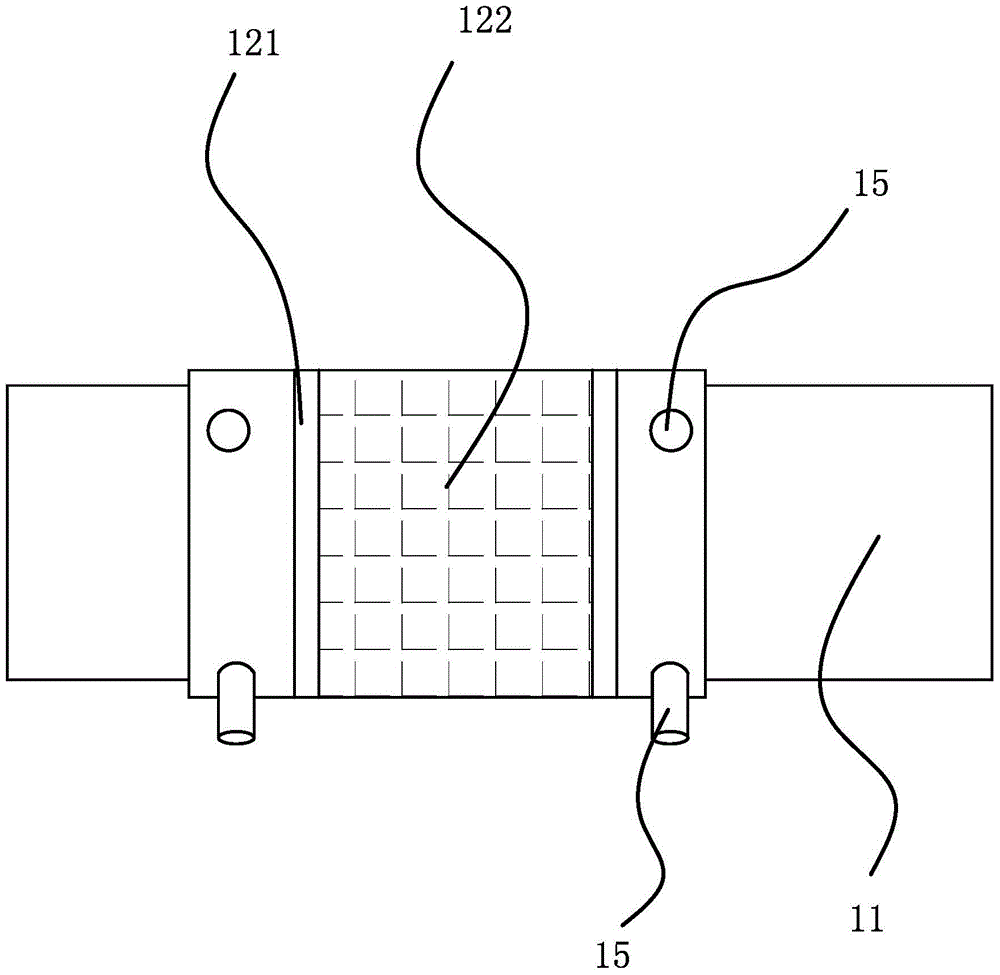

[0035] Such as figure 2 As shown, the front roller device 1 includes a front roller assembly and a top roller 13. The front roller assembly includes a cylindrical body 11 and an aluminum bushing 12 sleeved on the outer circumference of the body 11. The top roller 13 and the aluminum bushing 12 Frictional contact. There is a buckle structure between the aluminum bushing 12 and the main body 11 to fix both the circumferential direction and the axial direction. The body 11 is made of steel structure material, and the aluminum bushing 12 is made of aluminum material. The aluminum bushing 12 also has a protruding annular ring 121 on the outer circumference, and the height of the annular ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com