Interior wall coating and preparation method thereof

A technology for interior wall paint and raw materials, applied in the direction of coating and other directions, can solve the problems of easy yellowing, pungent smell, easy foaming of paint film, etc., and achieve the effects of good environmental protection, excellent effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: Get 30 parts of polyvinyl alcohol, 40 parts of water glass, 2 parts of talcum powder, 3 parts of quartz powder (174 μm), 1 part of ammonium persulfate, 22 parts of emulsifier Aerosol A-1022 parts, 13 parts of emulsifier Dowfax 2A, formazan Hydroxypropyl cellulose (5% aqueous solution) 5 parts, sodium bicarbonate 1 part, lauryl mercaptan 3 parts, NaOH 0.5 part, calcium stearate 2 parts, zinc oxide 1 part, gypsum 4 parts, borax 44 parts and 60 parts of water. The preparation method includes the following steps: take water according to the formula ratio, heat to 100°C, add polyvinyl alcohol until it is completely dissolved, add other materials, and stir for 35 minutes to obtain the product.

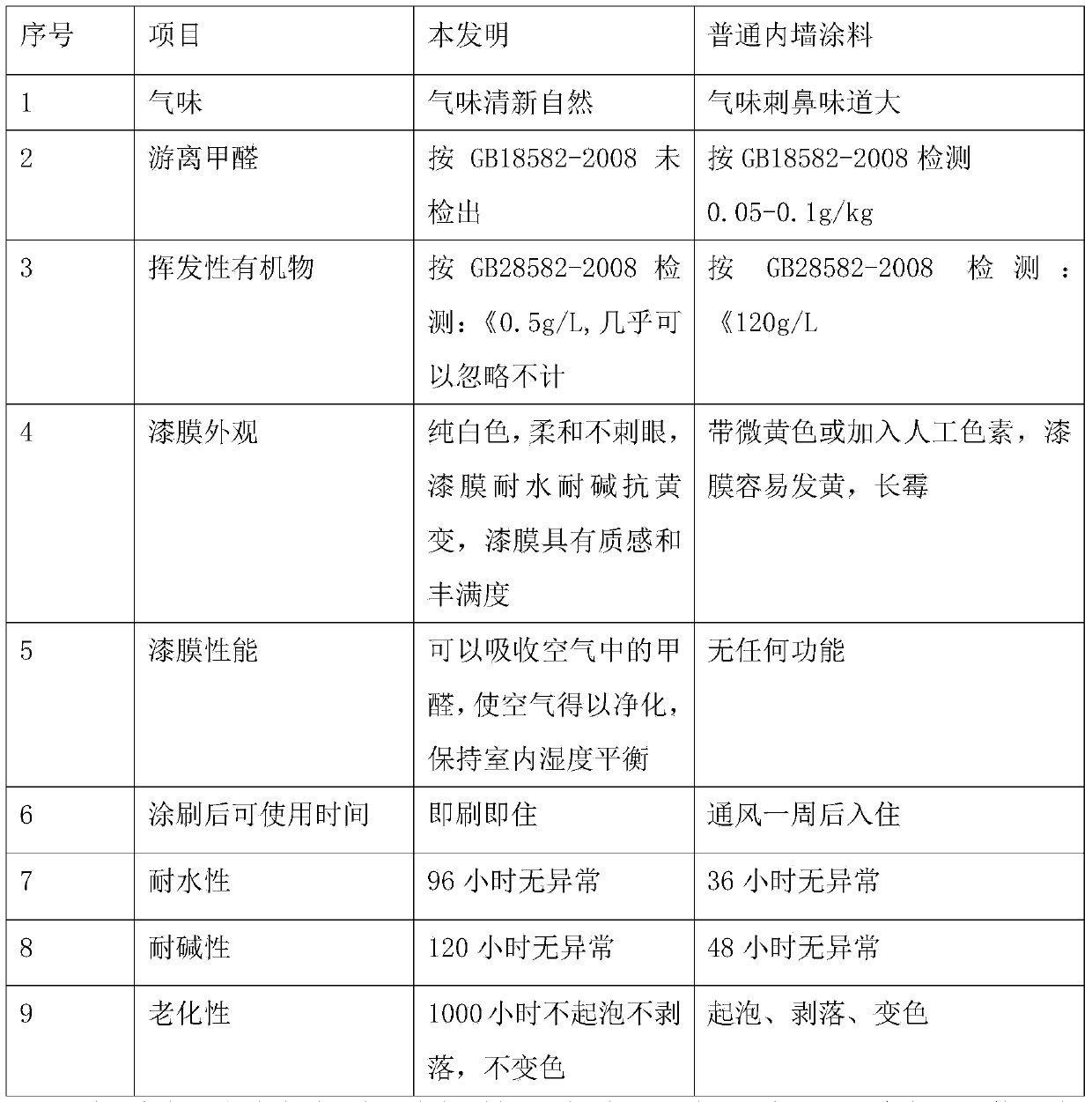

[0011] The main performance of the interior wall coating that present embodiment makes is as follows table.

[0012]

[0013] It shows that the interior wall paint of the present invention has excellent heat resistance and water resistance, good storage stability, goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com