Waterproof coating for internal wall and preparation method of waterproof coating

A waterproof coating and interior wall technology, applied in the direction of coating, etc., can solve the problems of easy cracking, aging, poor anti-mildew and anti-static effect of coating, heat resistance, frost resistance, waterproof function is not outstanding, etc., to achieve good waterproof function , good protection, good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

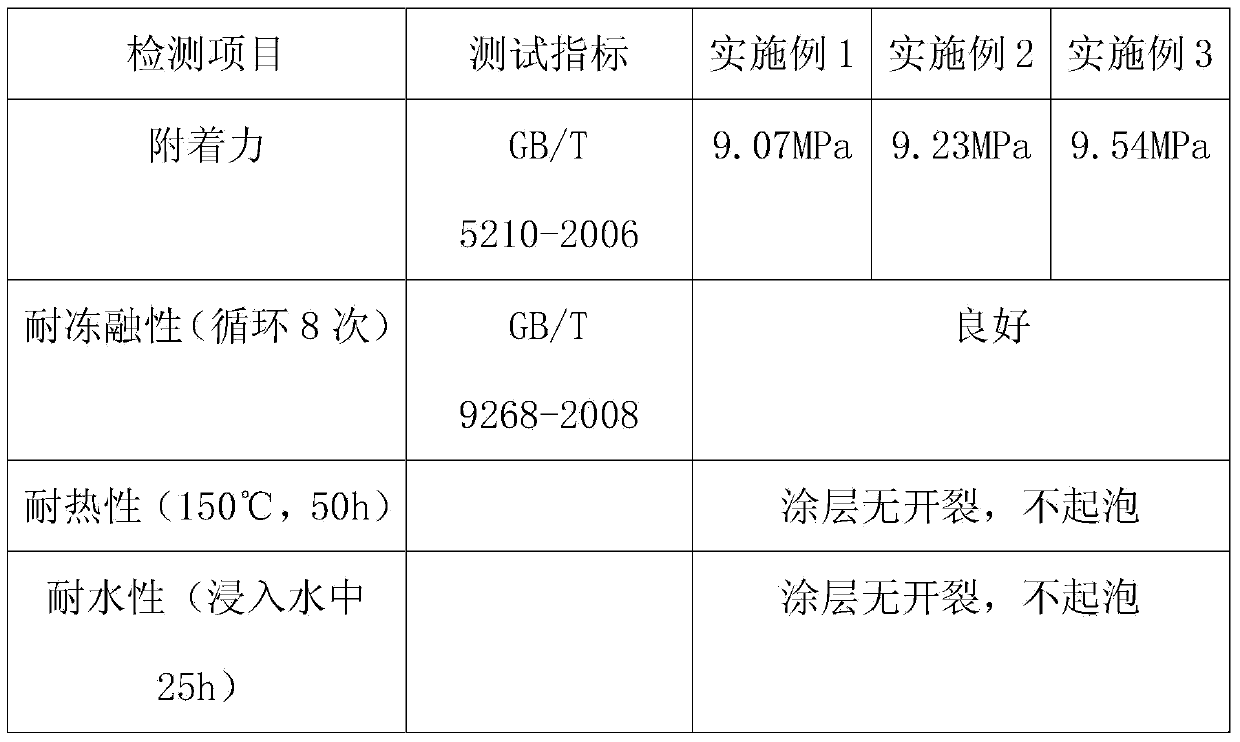

Examples

Embodiment 1

[0010] This embodiment provides a waterproof coating for interior walls, which contains the following components in parts by mass: 36 parts of water, 0.7 parts of sodium hexametaphosphate, 24 parts of pottery clay, 18 parts of calcined kaolin, 0.9 parts of polyoxyethylene ether, and styrene-acrylic emulsion 48 parts, 20 parts of silica sol, 2.7 parts of lauryl alcohol ester, 1 part of polycarbonate, 0.5 part of diethyl phthalate, 0.1 part of rigid polyvinyl chloride, 1.2 parts of sodium pentachlorophenate.

[0011] The preparation steps of a waterproof coating for interior walls are as follows: add water and sodium hexametaphosphate in a reaction kettle, stir evenly, add pottery clay, calcined kaolin, polyoxyethylene ether, stir and mix evenly, then add styrene-acrylic emulsion, silica sol , lauryl alcohol ester, polycarbonate, diethyl phthalate, mix evenly, finally add rigid polyvinyl chloride, sodium pentachlorophenate, mix evenly to get the finished product.

Embodiment 2

[0013] This embodiment provides a waterproof coating for interior walls, which contains the following components in parts by mass: 48 parts of water, 2.5 parts of sodium hexametaphosphate, 35 parts of pottery clay, 26 parts of calcined kaolin, 1.8 parts of polyoxyethylene ether, and styrene-acrylic emulsion 62 parts, 30 parts of silica sol, 5.4 parts of lauryl alcohol ester, 2.4 parts of polycarbonate, 1.2 parts of diethyl phthalate, 0.3 parts of rigid polyvinyl chloride, 3 parts of sodium pentachlorophenate.

[0014] The preparation steps of a waterproof coating for interior walls are as follows: add water and sodium hexametaphosphate in a reaction kettle, stir evenly, add pottery clay, calcined kaolin, polyoxyethylene ether, stir and mix evenly, then add styrene-acrylic emulsion, silica sol , lauryl alcohol ester, polycarbonate, diethyl phthalate, mix evenly, finally add rigid polyvinyl chloride, sodium pentachlorophenate, mix evenly to get the finished product.

Embodiment 3

[0016] This embodiment provides a waterproof coating for interior walls, which contains the following components in parts by mass: 42 parts of water, 1.6 parts of sodium hexametaphosphate, 30 parts of pottery clay, 22 parts of calcined kaolin, 1.5 parts of polyoxyethylene ether, and styrene-acrylic emulsion 55 parts, 25 parts of silica sol, 3.7 parts of lauryl alcohol ester, 1.7 parts of polycarbonate, 0.8 part of diethyl phthalate, 0.2 part of rigid polyvinyl chloride, 2.1 parts of sodium pentachlorophenate.

[0017] The preparation steps of a waterproof coating for interior walls are as follows: add water and sodium hexametaphosphate in a reaction kettle, stir evenly, add pottery clay, calcined kaolin, polyoxyethylene ether, stir and mix evenly, then add styrene-acrylic emulsion, silica sol , lauryl alcohol ester, polycarbonate, diethyl phthalate, mix evenly, finally add rigid polyvinyl chloride, sodium pentachlorophenate, mix evenly to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com