Inorganic nano modified phenolic resin brake pad and preparation process thereof

A phenolic resin, inorganic nanotechnology, applied in the field of brake pads, can solve the problems of insufficient wear resistance, low friction stability, heat resistance and other problems, to improve the stability of friction coefficient, high strength, improve The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

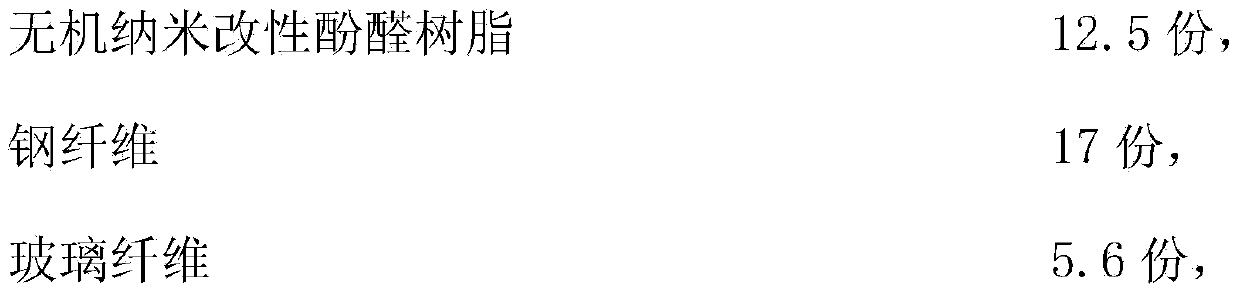

[0029] An inorganic nano-modified phenolic resin brake pad, its raw materials include by weight:

[0030]

[0031]

[0032] Wherein, the inorganic nano-modified phenolic resin is obtained by modifying the phenolic resin with modified nano-vermiculite, the water content is 0.5 wt%, and the free phenol content is 2 wt%.

[0033] Among them, the modified nano-vermiculite is prepared by the following process:

[0034] Put 8 parts of expanded vermiculite and 5 parts of sodium chloride into the mixer in parts by weight, and add hydrochloric acid, wherein the weight-to-volume ratio of vermiculite to hydrochloric acid g:ml is 10:15, and the concentration of hydrochloric acid is 4.5mol / L. Stirring at 65°C for 15 hours, centrifuging, filtering, and washing to obtain modified vermiculite;

[0035]Weigh the obtained modified vermiculite, add deionized water and mix evenly, the weight-to-volume ratio of modified vermiculite to deionized water g:ml is 10:100, add 35wt% cetyl trimethy...

Embodiment 2

[0041] An inorganic nano-modified phenolic resin brake pad, its raw materials include by weight:

[0042]

[0043] Wherein, the inorganic nano-modified phenolic resin is obtained by modifying the phenolic resin with modified nano-vermiculite, its water content is 0.8wt%, and the free phenol content is 1.5wt%.

[0044] Among them, the modified nano-vermiculite is prepared by the following process:

[0045] Put 13 parts of expanded vermiculite and 3 parts of sodium chloride into the mixer in parts by weight, add hydrochloric acid, wherein the weight-to-volume ratio of vermiculite to hydrochloric acid g:ml is 10:15, and the concentration of hydrochloric acid is 5.3mol / L, Stirring at 70°C for 10 hours, centrifuging, filtering, and washing to obtain modified vermiculite;

[0046] Weigh the obtained modified vermiculite, add deionized water and mix evenly, the weight-to-volume ratio of modified vermiculite to deionized water g:ml is 10:150, add 45wt% cetyl trimethyl on the basis...

Embodiment 3

[0052] An inorganic nano-modified phenolic resin brake pad, its raw materials include by weight:

[0053]

[0054] Wherein, the inorganic nano-modified phenolic resin is obtained by modifying the phenolic resin with modified nano-vermiculite, its water content is 0.65wt%, and the free phenol content is 1.8wt%.

[0055] Among them, the modified nano-vermiculite is prepared by the following process:

[0056] Put 12 parts of expanded vermiculite and 3.5 parts of sodium chloride in parts by weight in a mixer, add hydrochloric acid, wherein the weight-to-volume ratio of vermiculite to hydrochloric acid g:ml is 10:15, and the concentration of hydrochloric acid is 5mol / L, 68 Stirring at ℃ for 13 hours, centrifuging, filtering and washing to obtain modified vermiculite;

[0057] Weigh the obtained modified vermiculite, add deionized water and mix evenly, the weight-to-volume ratio of modified vermiculite to deionized water g:ml is 10:130, add 42.5wt% hexadecyl trimethylmethanol ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com