Photonic crystal microsphere as well as preparation method and application thereof

A technology of photonic crystal microspheres and photonic crystals, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of low resolution of encoded signals, poor stability of photonic crystal microspheres, and not bright colors, etc., and achieve bright color development , shorten the preparation cycle, and reduce the time required for coding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the photonic crystal microsphere provided by the invention comprises the following steps:

[0037] (1) Preparation of photonic crystal core material: uniformly mix styrene, N-isopropylacrylamide, surfactant (sodium lauryl sulfate) and initiator, and emulsion polymerization occurs at 60°C to 80°C for 5 Hours to 10 hours, the polystyrene-poly(N-isopropylacrylamide) copolymer nanoparticle suspension is prepared, and its mass fraction is 10% to 50%. The mass ratio of the styrene, N-isopropylacrylamide, sodium dodecylsulfonate and initiator is 10-20:0.1-1:1.6-2.6:0.01-0.09. The photoinitiator is preferably potassium persulfate. Wherein the consumption of sodium dodecyl sulfonate can control the average particle diameter of polystyrene-poly(N-isopropylacrylamide) copolymer nanoparticles.

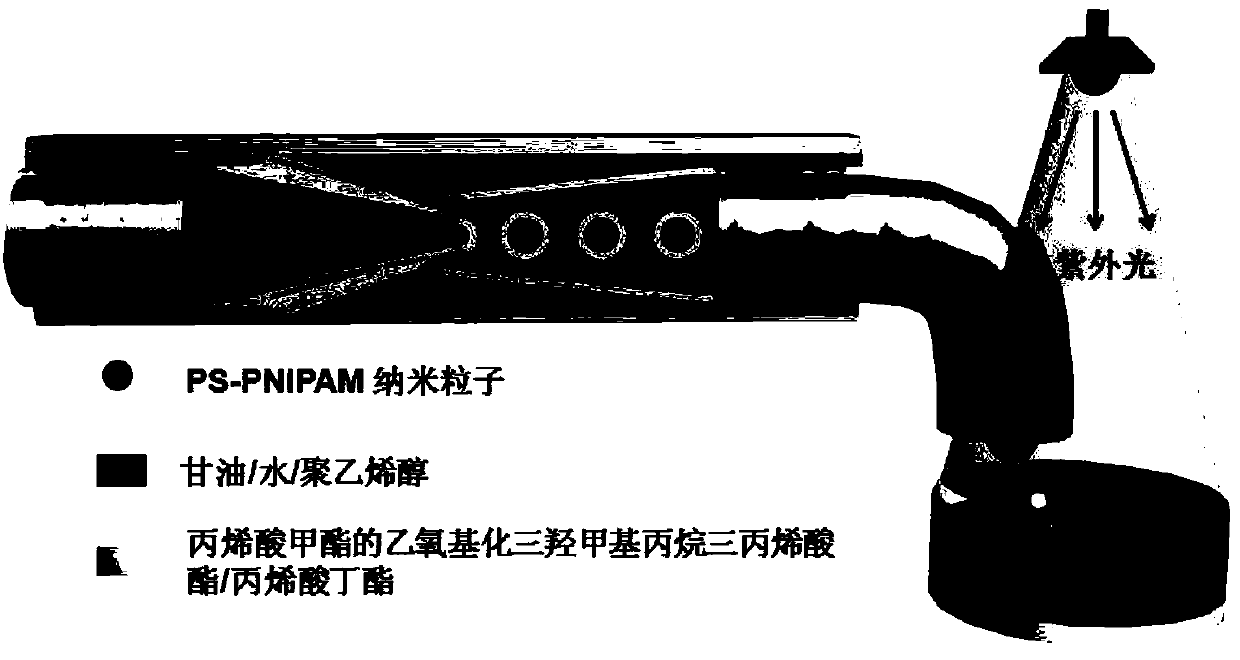

[0038] (2) Preparation of photonic crystal microsphere precursor: adopting microfluidic technology, with the polystyrene-poly(N-isopropylacrylamide) copolymer na...

Embodiment 1

[0045] Embodiment 1 blue photonic crystal microsphere and its preparation

[0046] A blue photonic crystal microsphere, comprising a photonic crystal core and a photopolymer shell, see figure 2 A; The core diameter of the photonic crystal is 270 μm, which is a polystyrene-poly(N-isopropylacrylamide) copolymer nanoparticle suspension, and the polystyrene-poly(N-isopropylacrylamide) copolymer The average particle size of the nanoparticle is 110nm; the photopolymer shell is a hydrophobic photoinitiated resin with a thickness of 30μm. The hydrophobic resin is ethoxylated trimethylolpropane triacrylate containing 1% by mass of acrylate.

[0047] Described blue photonic crystal microsphere, its preparation method, comprises the following steps:

[0048] (1) Preparation of photonic crystal core material: uniformly mix styrene, N-isopropylacrylamide and initiator, and undergo emulsion polymerization for 5 hours at 60°C to obtain the polystyrene-polyisopropylpropylene Amide copolym...

Embodiment 2

[0052] Embodiment 2 green photonic crystal microsphere and its preparation

[0053] A green photonic crystal microsphere, comprising a photonic crystal core and a photopolymer shell; the photonic crystal core diameter is 280 μm, which is polystyrene-poly(N-isopropylacrylamide) copolymer nanoparticle suspension, the The average particle size of the polystyrene-poly(N-isopropylacrylamide) copolymer nanoparticles is 140nm, the photopolymer shell is a hydrophobic photoinitiating resin, and the thickness is between 40μm. The hydrophobic resin is ethoxylated trimethylolpropane triacrylate containing 1% by mass of acrylate.

[0054] Described green photonic crystal microsphere, its preparation method, comprises the following steps:

[0055] (1) Preparation of photonic crystal core material: uniformly mix styrene, N-isopropylacrylamide and initiator, and undergo emulsion polymerization for 6 hours at 70°C to obtain the polystyrene-poly(N-isopropylacrylamide) Propylacrylamide) copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com