Pure organic biological growth induction factor

A technology of organic organisms and inducers, applied in the direction of organic fertilizers, etc., can solve problems such as backward production technology, long preparation cycle, and complicated process, and achieve the effects of high input-output ratio, easy absorption, and high additional income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

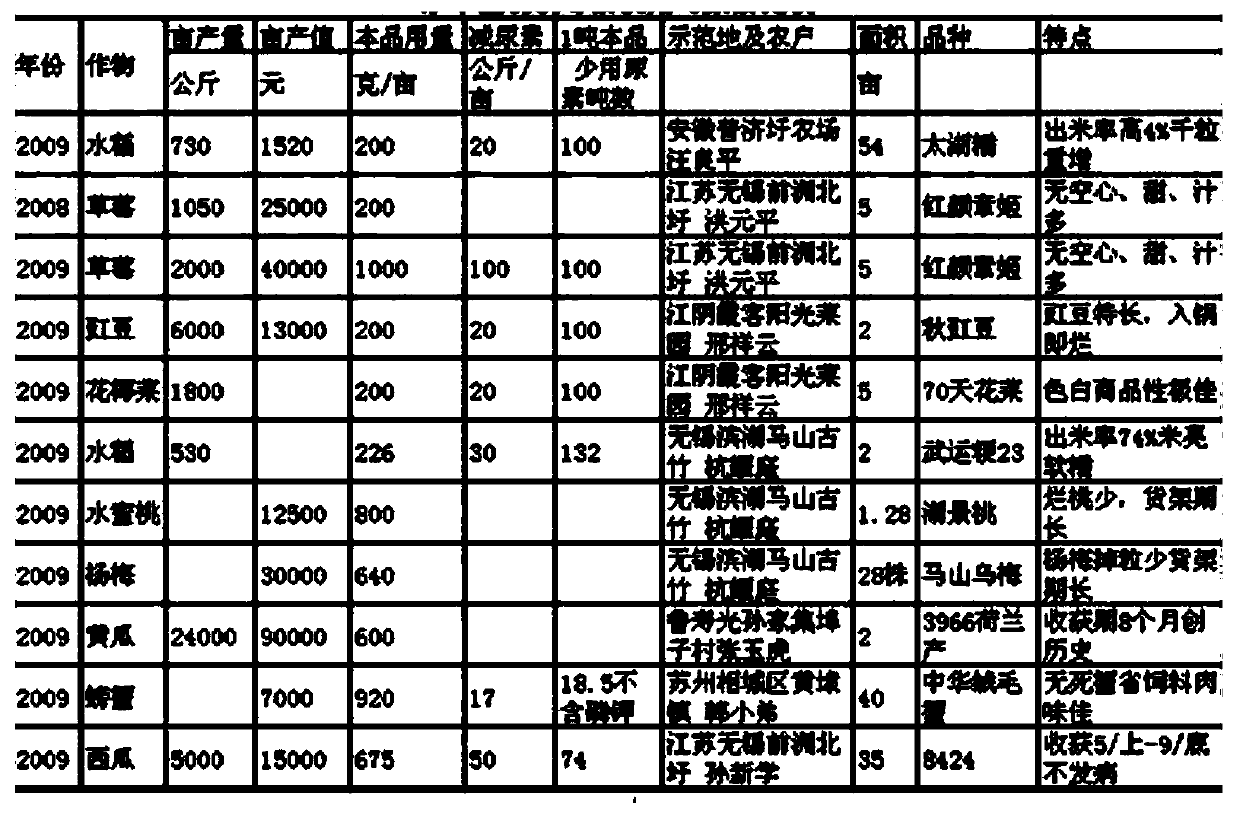

Examples

Embodiment 1

[0022] Raw materials of the present invention: 30kg of beans (10kg of broad beans, 10kg of long beans), miscellaneous grains (10kg of corn, 10kg of potatoes, and 10kg of straw), 10kg of celery, 10kg of cabbage, and 30kg of the extract of yellow grass etc. are soaked in warm water for 3-24 hours , through mechanical crushing, 40-mesh sieving, slag removal and precipitation, pressing, adding plant protease, for example, adding enzyme at an amount of 150,000 units / KG protein, and reacting in a jacketed enamel reaction tank at 23-37°C for 4 hours Afterwards, add 30% concentration of hydrochloric acid (HCl) to keep the pH at 1, heat to 100-110°C and react for 3-12 hours, decolorize with activated carbon after cooling, remove slag by plate and frame pressure filtration, then desalt and reduce pressure through exchange resin Concentrate to amino nitrogen ≥ 1.0%, which is the high-purity bio-organic plant nutrient solution of the present invention.

[0023] 0.5-0.85 tons of final prod...

Embodiment 3

[0025] Application on soybeans. The product of the present invention is diluted with water 1000-3000 times in the germination stage of soybean growth, and sprayed 2-4 times in the middle stage. The yield per mu of the test group was 1000 kg, which was 300%-500% higher than that of the control group of 220 kg. After the bean products are made, the color, flavor and shape are all good, and the oil yield and protein yield are significantly better than those of the control product, and the economic benefits are very obvious. The total amount of application per mu is about 40 grams to 1000 grams, the amount is correspondingly large, and the yield is correspondingly high. The cystic nematode disease resistance experiment was carried out in the control group and the test group at the same time, and the soybean seedlings in the test group were not affected.

Embodiment 4

[0027] Application on strawberries. Dilute the pure organic bio-growth inducer of the present invention by 1000--3000 times, and spray 4-N times for root irrigation of the strawberry in the growth period, flowering period and fruit-setting period respectively. In the test group, the weight of a single strawberry fruit was 149 grams, and the weight of a large fruit increased by 300%, with more flowers and more fruits, an average of 6,000 catties per mu, and an increase of 300% or more. Can effectively prevent strawberry anthracnose, fusarium wilt. The amount of application per mu is about 200-800 grams of inducer powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com