Phase-change insulating flexible facing material and preparation method thereof

A technology for thermal insulation flexible and decorative materials, which is applied in the field of building thermal insulation and decoration materials, can solve the problems that the thermal insulation effect of coatings is not obvious, the thermal energy cannot be fully utilized, and the production cost of thermal insulation boards is high, so as to broaden the scope of use, simplify the construction process, and improve the decoration. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

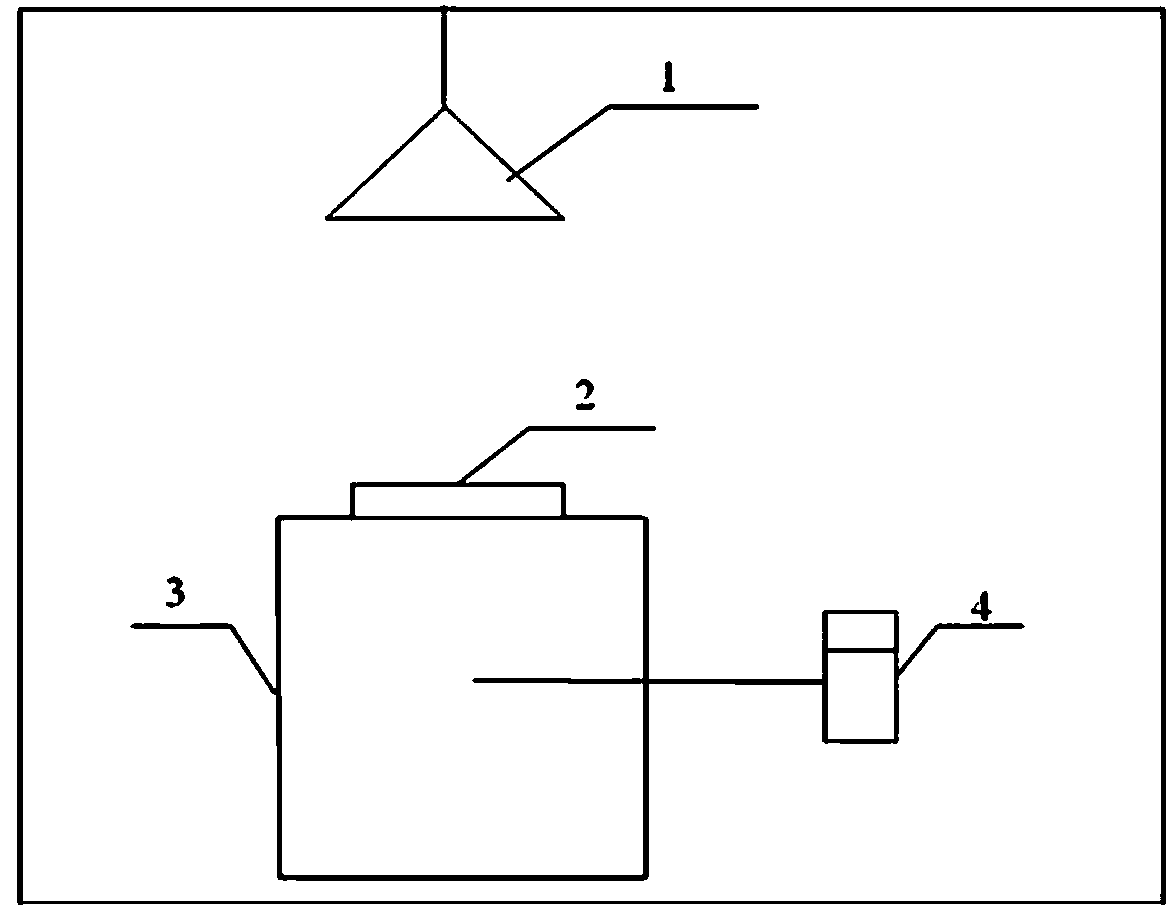

Image

Examples

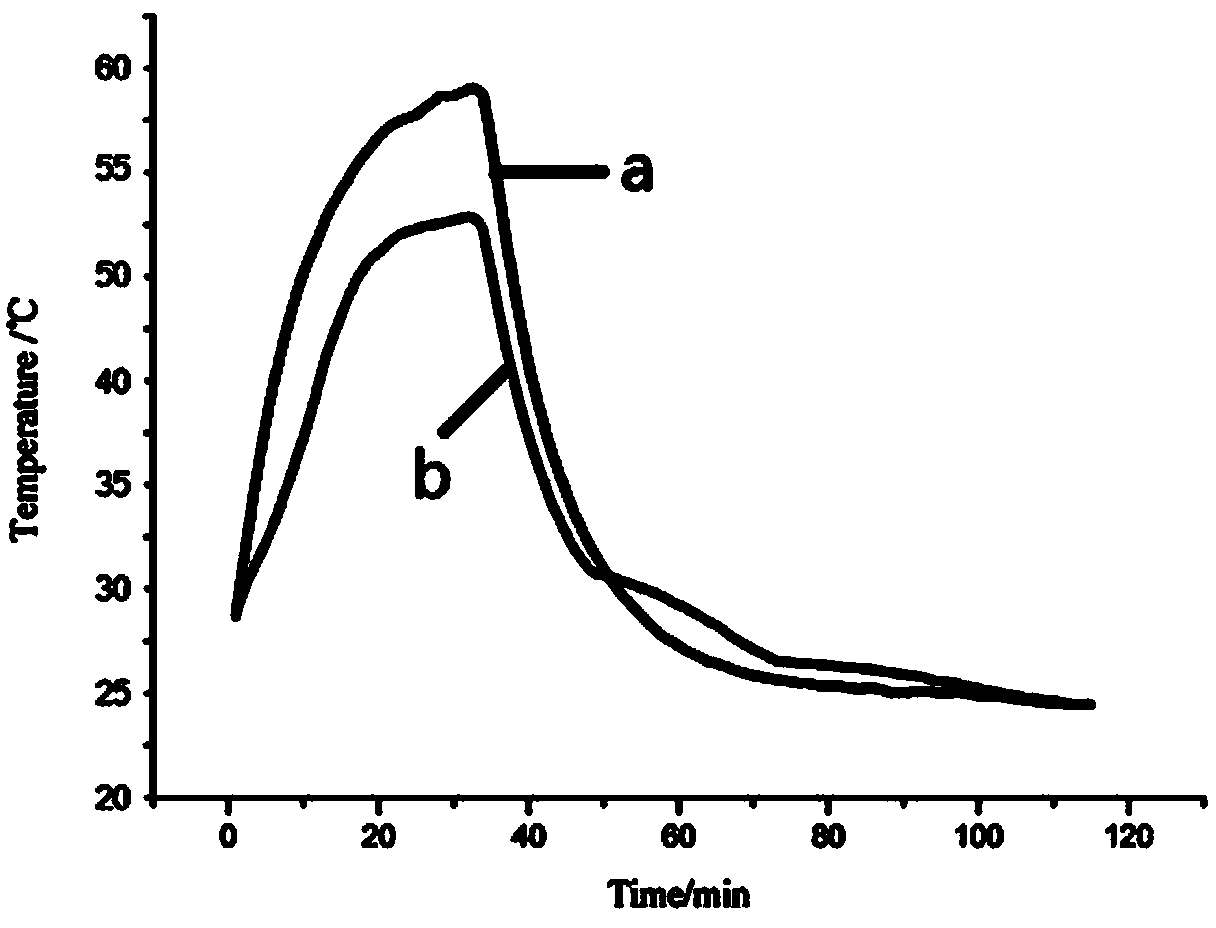

Embodiment 1

[0033] Example 1: Kaolin 40%, MicroPCMs 6%, self-crosslinking acrylate emulsion 30%, acrylic acid 3%, additives 2.5%, cetyltrimethylammonium bromide 0.5%, sodium-based organobentonite 4% , water 14% batching by mass parts. Add self-crosslinking acrylate emulsion, water, cetyltrimethylammonium bromide, additives, and acrylic acid to the disperser and mix at a high speed of 2000r / min, then slowly add sodium-based bentonite, when the bentonite is fully dispersed , reduce the speed to 800r / min, slowly add MicroPCMs, stir for 20min; finally slowly add kaolin. Scrape the obtained mixture on the mold in batches, with a thickness of 4mm, and then put it into a 50°C oven for curing for 4h. The material is peeled off from the mold, baked in a 100°C oven for 1 hour, taken out, trimmed and polished to obtain a phase-change thermal insulation flexible facing material.

Embodiment 2

[0034] Example 2: Attapulgite 30%, MicroPCMs 5%, self-crosslinking acrylate emulsion 40%, acrylic acid 2%, additives 2.5%, cetyltrimethylammonium bromide 0.5%, sodium-based organobentonite 3 %, water 17% batching by mass parts. Add self-crosslinking acrylate emulsion, water, cetyltrimethylammonium bromide, additives, and acrylic acid to the disperser and mix at a high speed of 2000r / min, then slowly add sodium-based bentonite, when the bentonite is fully dispersed , reduce the speed to 800r / min, slowly add MicroPCMs, stir for 20min; finally slowly add attapulgite. Scrape the obtained mixture on the mold in batches with a thickness of 5mm, and then put it into an oven at 60°C for 4 hours for curing. The material is peeled off from the mold, baked in an oven at 110°C for 1 hour, taken out, trimmed and polished to obtain a phase-change thermal insulation flexible facing material.

Embodiment 3

[0035] Example 3: Montmorillonite 40%, MicroPCMs 9%, self-crosslinking acrylate emulsion 25%, methacrylic acid 2%, additives 2.5%, tetradecyltrimethylammonium bromide 0.5%, lithium-based Organic bentonite 3%, water 18% are batched by mass parts. Add self-crosslinking acrylate emulsion, water, tetradecyltrimethylammonium bromide, additives, and methacrylic acid to the disperser and mix at a high speed of 2000r / min, then slowly add lithium-based bentonite, when the bentonite is fully After dispersion, reduce the speed to 800r / min, slowly add MicroPCMs, stir for 20min; finally slowly add montmorillonite. Scrape the obtained mixture on the mold in batches with a thickness of 3mm, and then put it into an oven at 70°C for 3 hours for curing. The material is peeled off from the mold, baked in an oven at 110°C for 2 hours, taken out, trimmed and polished to obtain a phase-change thermal insulation flexible facing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com