Device for purifying toxic sewage by utilizing three-stage bio-membrane reactor and method for purifying toxic sewage by using device

A biofilm reactor, three-stage technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of unreasonable packing structure, unusable toxic waste water, Poor impact resistance and other problems, to achieve the effect of reducing sewage turbidity, improving advanced oxidation effect, and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

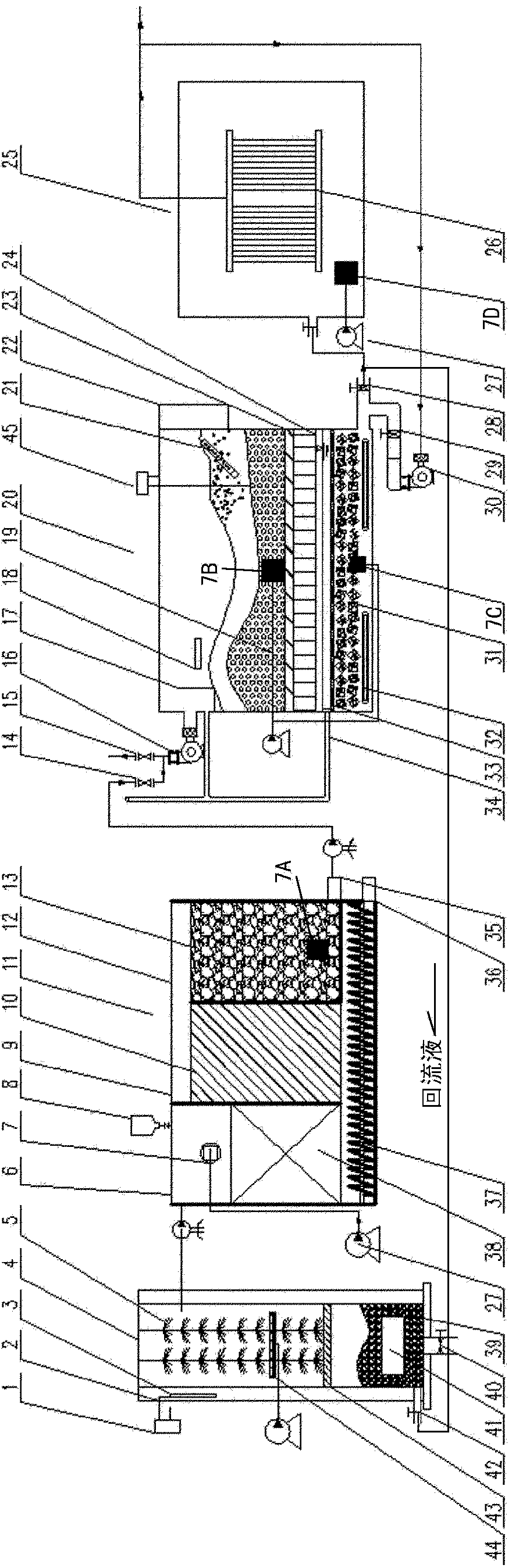

[0029]The device for purifying toxic sewage with a three-stage biofilm reactor provided by the present invention can efficiently purify pollutants (such as nitrogen, phosphorus, organic matter, microorganisms, pathogenic bacteria, suspended particles, colloids, etc.) in toxic sewage.

[0030] see figure 1 . The device for purifying toxic sewage with a three-stage biofilm reactor provided by the present invention, its main structure includes:

[0031] The three-stage biofilm reactor 4 is provided with a mud discharge hole 40 at the bottom, and a mixer 41 is arranged above the mud discharge hole 40, and a low-density flow packing 39 is laid around the mixer 41, and the low-density flow filler 39 adopts nanometer powder. Coal Ash Sintered Molecular Sieve. A steel mesh 43 is placed above the mobile packing 39 to prevent the upward flow of the mobile packing 39. A composite packing 5 is arranged above the steel mesh 43. The composite packing 5 is grown on the surface of the packi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com