Thermal insulation can, thermal insulation can plate and manufacturing method of thermal insulation can plate

A production method and technology of an insulated box, applied in the field of heat preservation, can solve problems such as increased cost, less purchase volume, and inability to fold, and achieve the effects of solving environmental protection and printing problems, saving space in logistics links, and reducing storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The production method of the new insulation box plate is as follows:

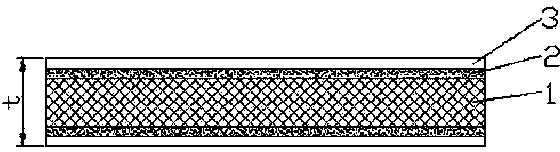

[0026] 1. Production of board core: The mixed material of 95% polystyrene PS particles and 5% polyethylene PE particles is foamed by foaming equipment to form a 2.5-3.0mm thick board core, and the finished board core is Output in roll form. The core of the coil is stored in a natural state at room temperature for half a month and enters the maturation period. At the same time, the waste gas in the plate is discharged, and the mature core enters a usable state.

[0027] 2. Fusion of aluminized layer: install two rolls of cured plate core and two rolls of aluminized film on the tape casting compound machine, and fuse the aluminized film and plate core together through the heating and extrusion of the equipment fusion mechanism to form 5-6mm thick double-layer aluminized film insulation box plate. During the fusion process, when the temperature of the heating roller reaches 125-135°C, the surface of t...

Embodiment 2

[0031] The production method of the new insulation box plate is as follows:

[0032] 1. Production of board core: The mixed material of 95% polystyrene PS particles and 5% polyethylene PE particles is foamed by foaming equipment to form a 2.5-3.0mm thick board core, and the finished board core is Output in roll form. The core of the coil is stored in a natural state at room temperature for half a month and enters the maturation period. At the same time, the waste gas in the plate is discharged, and the mature core enters a usable state.

[0033] 2. Fusion of aluminized layer: The board core passes through the glue coating equipment, and a layer of environmentally friendly glue is evenly rolled on the upper and lower surfaces; the aluminized film and the board core coated with glue are pressed together, and the pressing force is 5T.

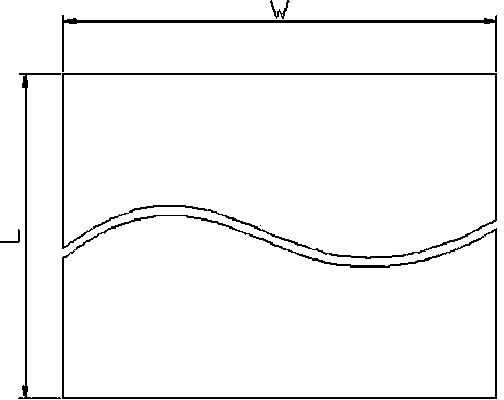

[0034] 3. Cooling of the plate: The fully fused plate is conveyed from the fusion part, has a high temperature, and is easily deformed by direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com