Carrying gripper for automobile seat

A technology for car seats and handling hands, which is applied in the directions of transportation and packaging, conveyor objects, metal processing, etc. It can solve the problems affecting the quality of the seat, the damage of the seat surface, and the deformation of the seat, so as to improve work efficiency and improve Efficiency, the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

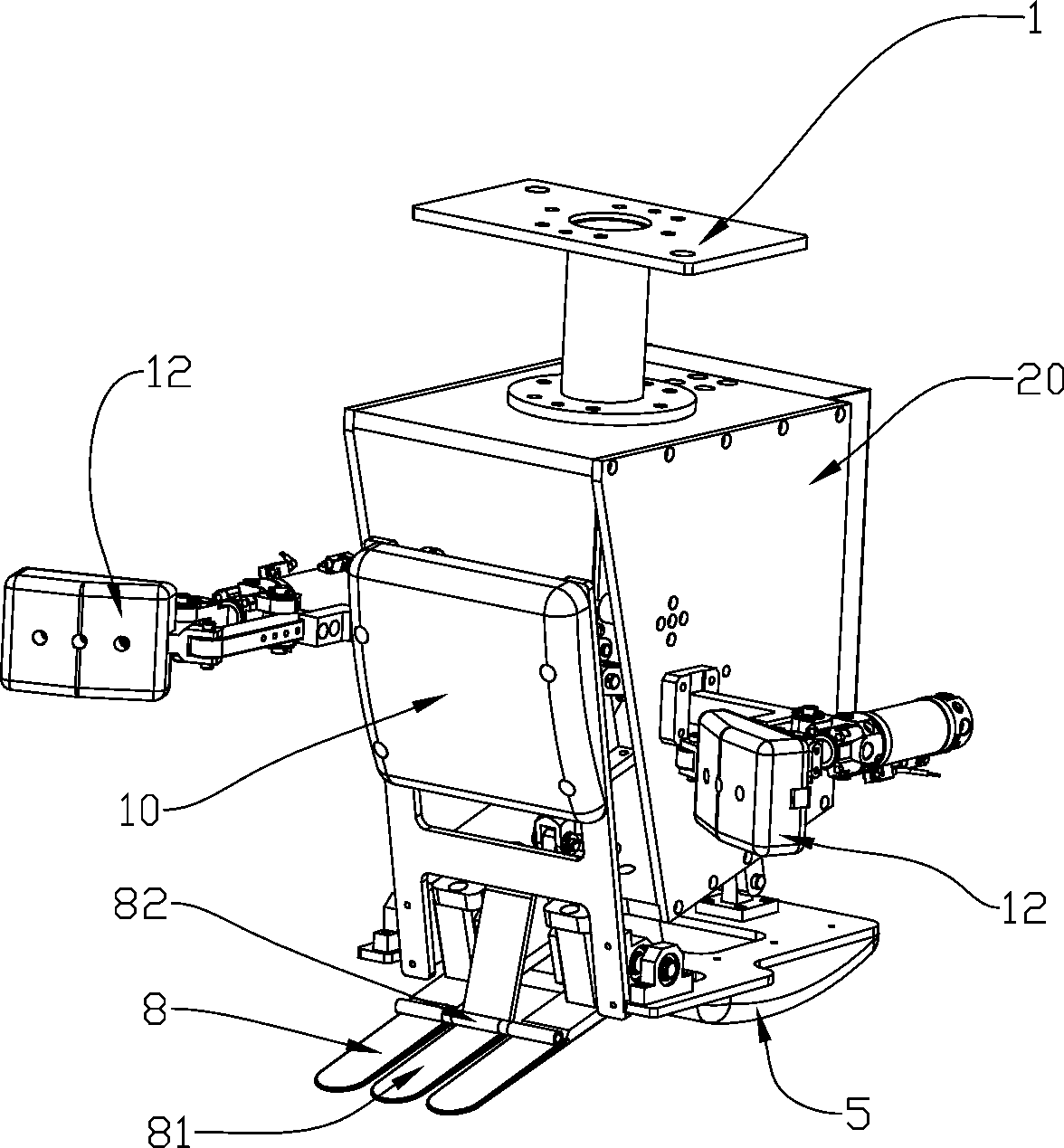

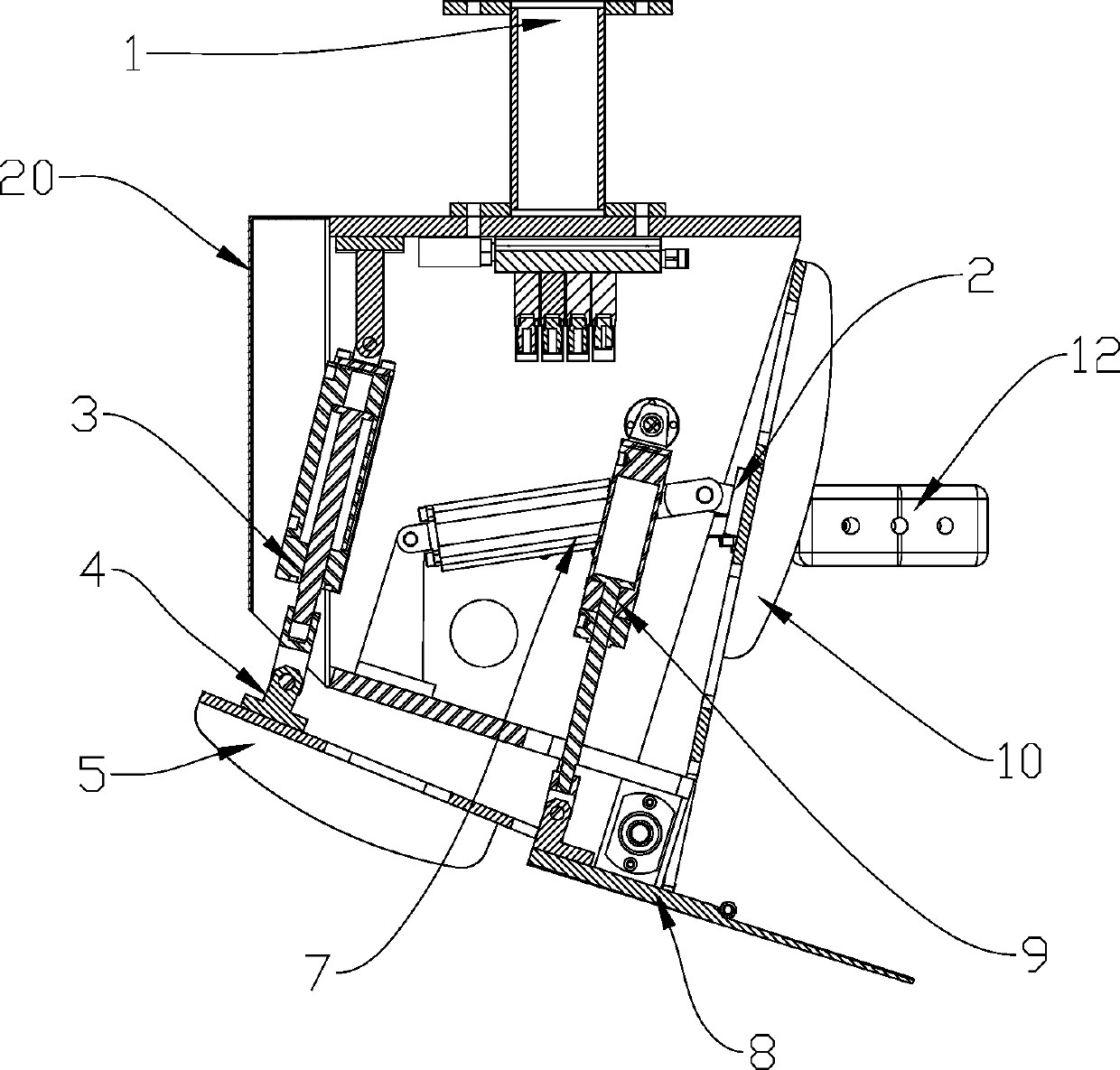

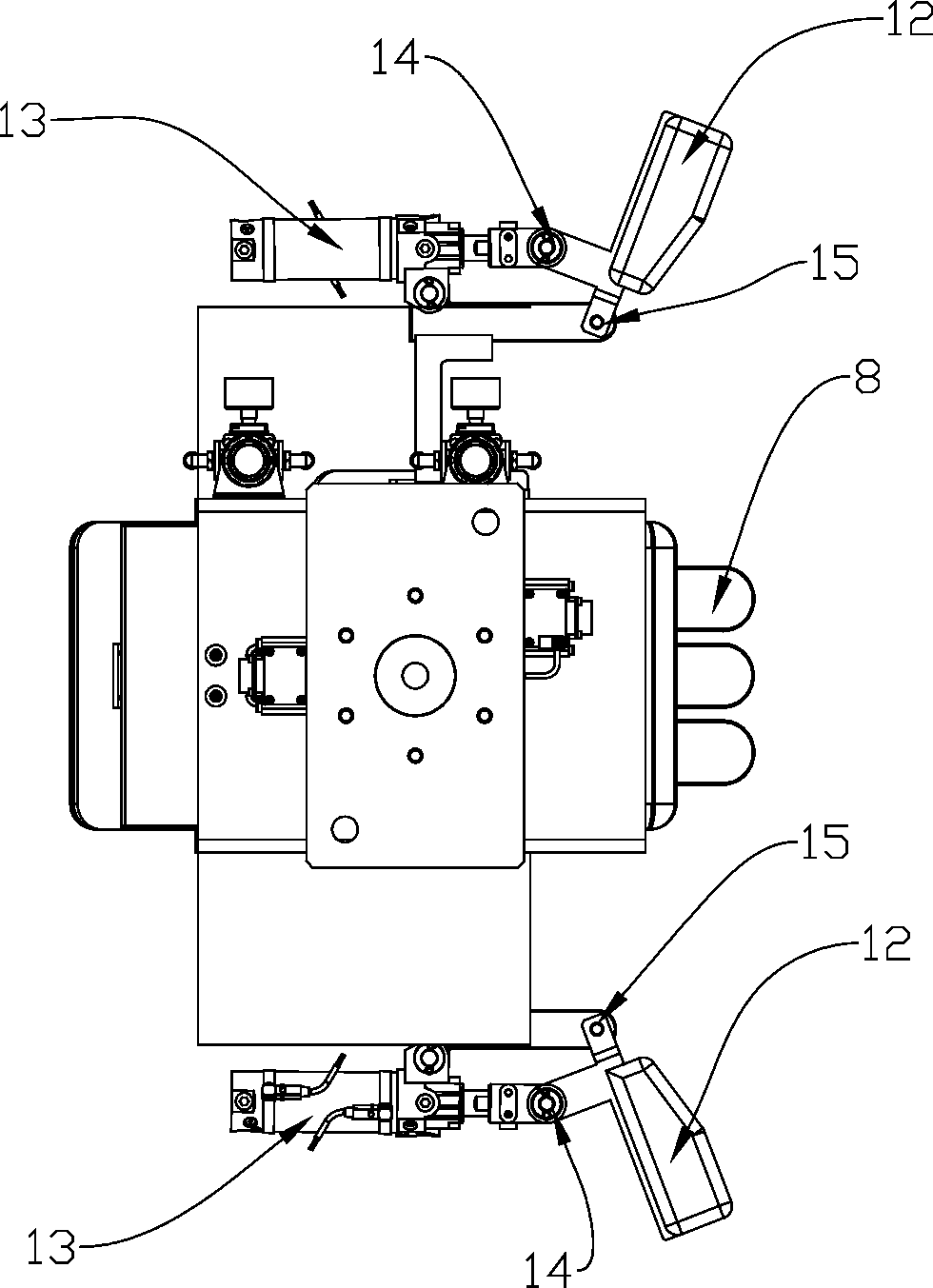

[0023] See Figure 1 to Figure 3 , the car seat handling claws, including the body 20, the body 20 is provided with several boards 8 for inserting into the gap between the seat base and the backrest, in this embodiment, there are 3 boards arranged side by side, wherein The boards on both sides are fixed on the support, and the middle board is a movable board 81. The movable board 81 is fixed to the boards 8 on both sides through a hinge, and one end of the movable board 81 is connected to the lifting cylinder 9. The push rods are connected, and the movable inserting plate 81 can rotate around the rotating shaft 82 during lifting, and the other end of the lifting cylinder 9 is hinged on the body 20 .

[0024] The body 20 is also provided with a clamping part for clamping the seat, and the clamping part is a left-right symmetrical side clamp blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com