Weighing and sorting machine for cork sheet of badminton ball head

A cork chip and badminton technology, applied in the field of badminton production, can solve the problems of difficult precise control of the acceleration and speed of the manipulator, instability, long distance, etc., and achieve the effect of stable automatic weighing and sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

[0027] Please refer to the accompanying drawings, embodiments of the present invention include:

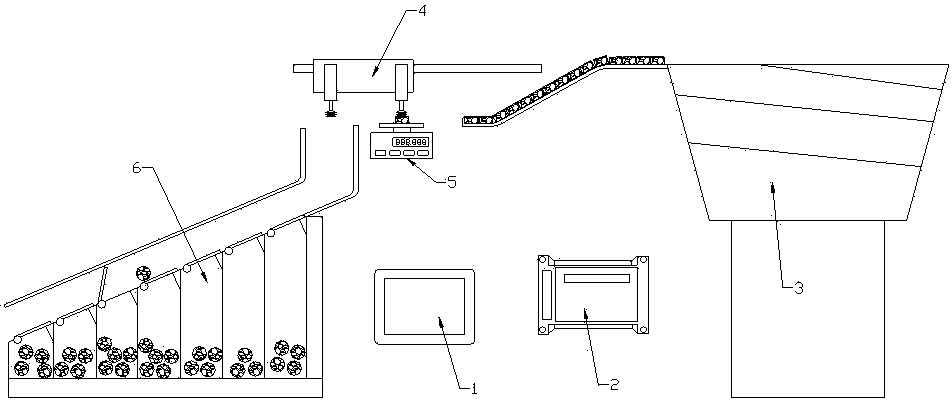

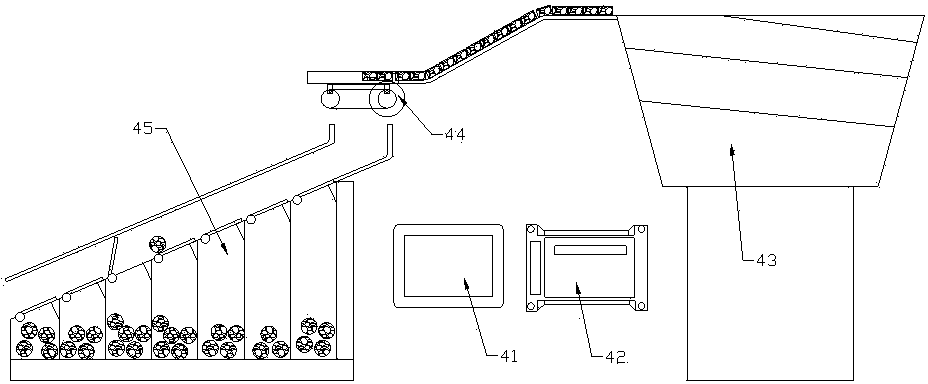

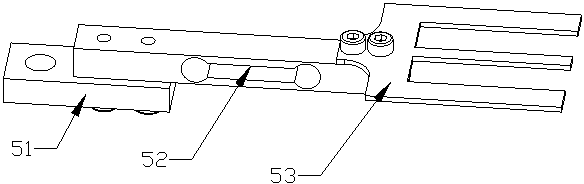

[0028] Such as figure 2 , Figure 4 , Figure 5 , Figure 6 As shown, the automatic weighing and sorting machine for badminton head cork chips of the present invention includes a touch screen man-machine interface 41, a PLC controller 42, a vibrating plate feeding device 43, a weighing device 44, and a chute valve blanking device 45. The weighing device 44 includes a load cell base 51, a load cell 52, a weighing bracket 53, a base plate 601, a synchronous motor 602, a bearing seat 603, a bearing seat 604, a bearing seat 605, a bearing seat 606, a shaft 607, and a shaft 608, timing pulley 609, timing pulley 610, timing belt 611, timing pulley 612, timing pulley 613, timing belt 614, cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com