Method for preparing copper-based catalyst

A technology of copper-based catalyst and zinc oxide, which is applied in the field of preparation of copper-based catalysts, can solve the problems of low catalytic efficiency, poor recycling activity, large amount of copper-based catalysts, etc., achieve high catalytic activity, shorten reaction time and dosage little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

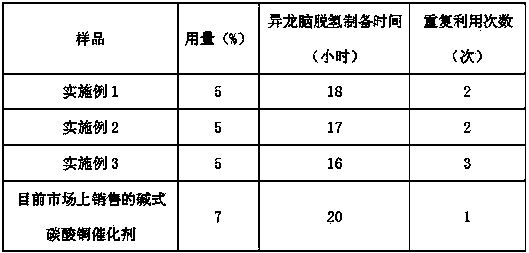

Examples

Embodiment 1

[0015] The preparation method of this copper-based catalyst comprises the following steps:

[0016] A, 60g of sodium carbonate is dissolved in water to obtain sodium carbonate solution, which is set aside;

[0017] B, first 90g copper sulfate is dissolved in 60 DEG C of water to prepare a copper sulfate solution, then under stirring conditions, add the sodium carbonate solution prepared in step A to the copper sulfate solution to react, when the pH of the reaction solution When value reaches 10, stop adding described sodium carbonate solution, filter, collect the precipitate that reaction produces;

[0018] C, the precipitate that B step is made is washed with water, until the aqueous solution of described precipitate checks without sulfate radical with barium chloride;

[0019] D. Add 5g of zinc oxide to the aqueous solution of the precipitate treated in step C and stir evenly, then filter it with a cloth bag, centrifuge the obtained filtrate, and dry the obtained lower sedi...

Embodiment 2

[0021] The preparation method of this copper-based catalyst comprises the following steps:

[0022] A, 70g sodium carbonate is dissolved in water, makes sodium carbonate solution, subsequent use;

[0023] B, first 100g of copper sulfate is dissolved in water at 70°C to prepare a copper sulfate solution, then under stirring conditions, add the sodium carbonate solution prepared in step A to the copper sulfate solution to react, when the reaction solution When the pH value reaches 10, stop adding the sodium carbonate solution, filter, and collect the precipitate produced by the reaction;

[0024] C, the precipitate that B step is made is washed with water, until the aqueous solution of described precipitate checks without sulfate radical with barium chloride;

[0025] D. Add 10 g of zinc oxide to the aqueous solution of the precipitate treated in step C and stir evenly, then filter it with a cloth bag, centrifuge the obtained filtrate, and dry the obtained lower layer sediment ...

Embodiment 3

[0027] The preparation method of this copper-based catalyst comprises the following steps:

[0028] A, 80g of sodium carbonate is dissolved in water to obtain sodium carbonate solution, which is set aside;

[0029] B, first 110g of copper sulfate is dissolved in water at 80°C to prepare a copper sulfate solution, then under stirring conditions, add the sodium carbonate solution prepared in step A to the copper sulfate solution to react, when the reaction solution When the pH value reaches 10, stop adding the sodium carbonate solution, filter, and collect the precipitate produced by the reaction;

[0030] C, the precipitate that B step is made is washed with water, until the aqueous solution of described precipitate checks without sulfate radical with barium chloride;

[0031] D. Add 15g of zinc oxide to the aqueous solution of the precipitate treated in step C and stir evenly, then filter it with a cloth bag, centrifuge the obtained filtrate, and dry the obtained lower sedime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com