Strap splitting device arranged on zipper machine and used for zipper head installation

A technology of zipper machine and zipper head, which is applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problem that the spacing cannot be reduced, and achieve the effect of simple structure, stable working state, and simple setting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

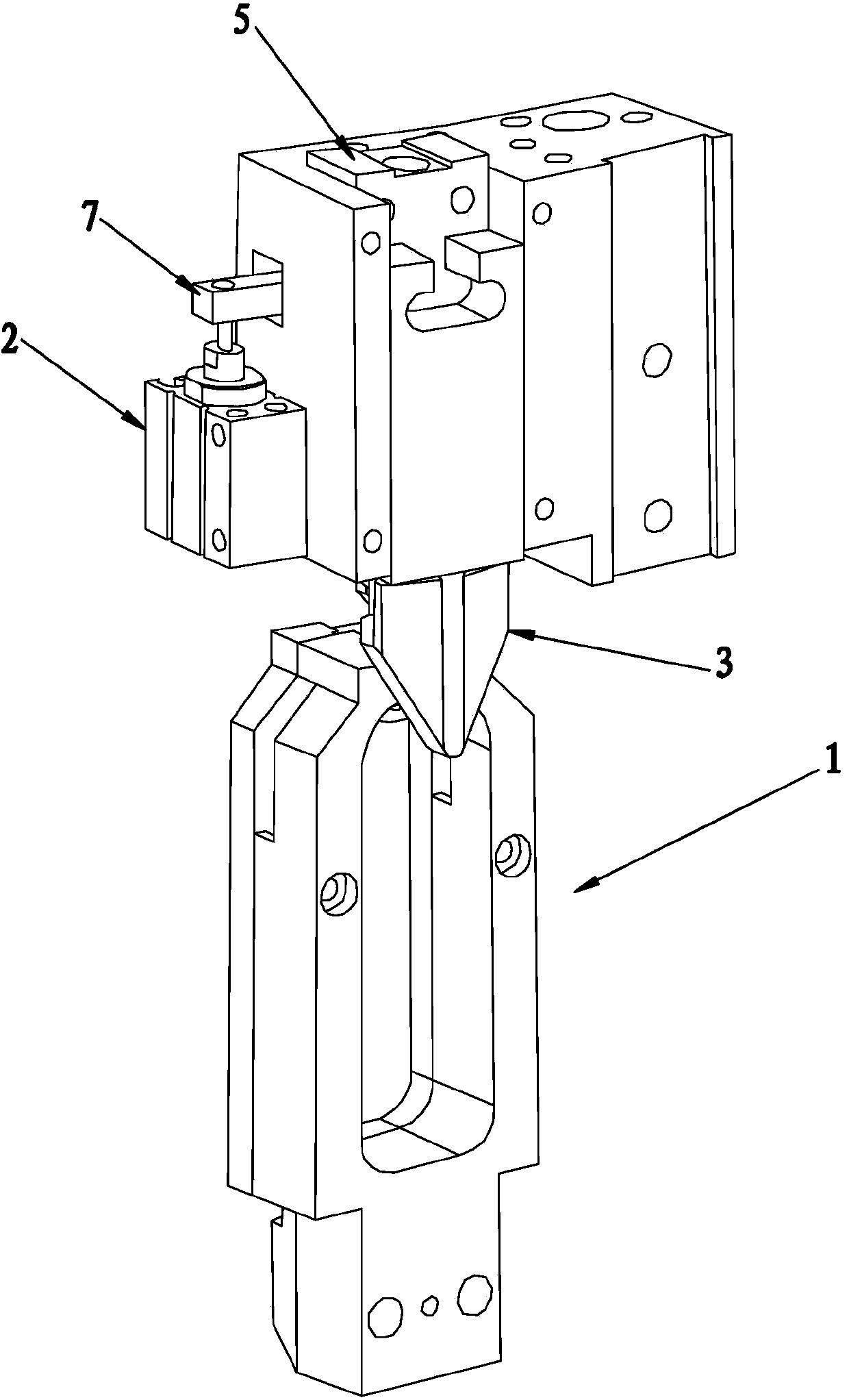

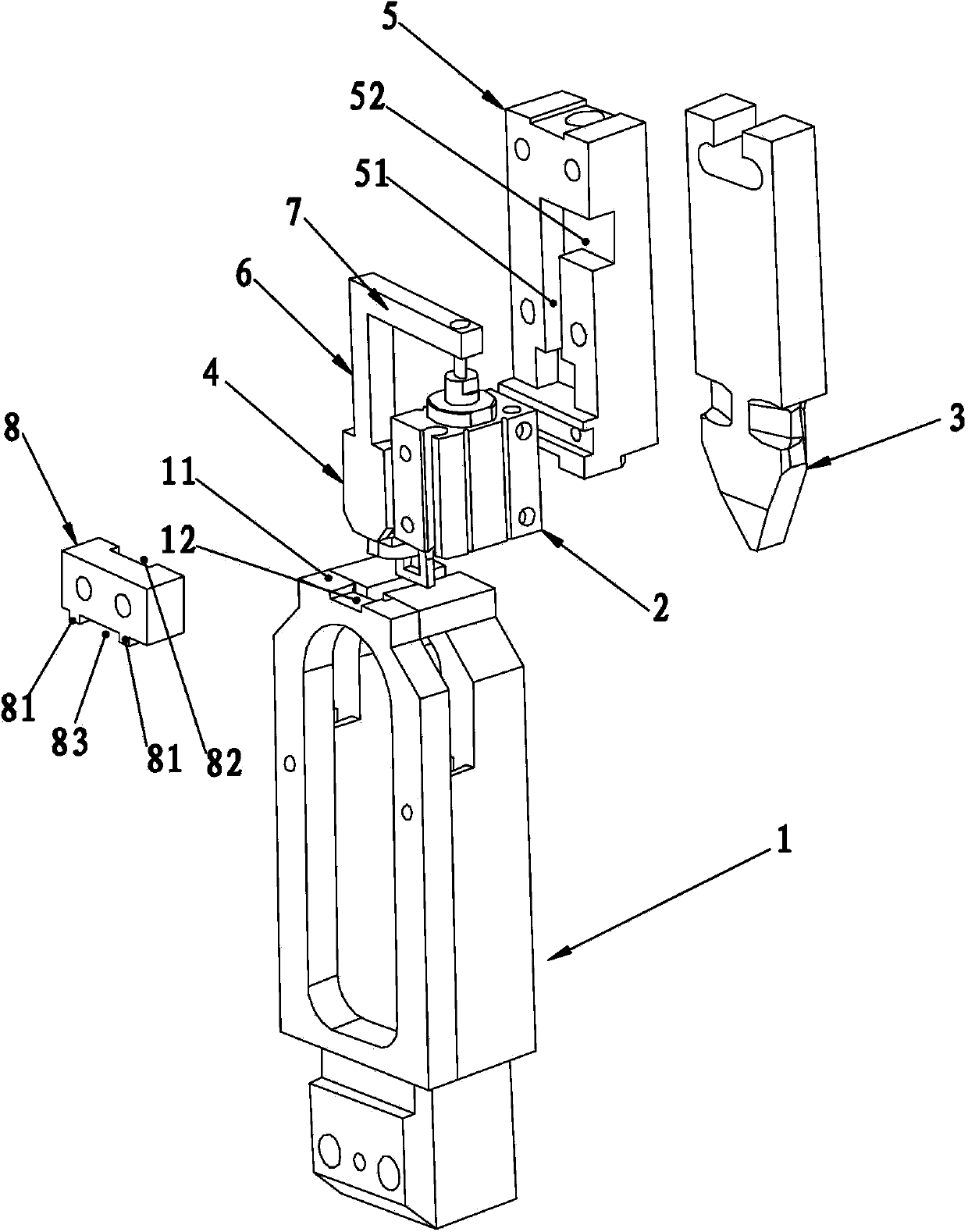

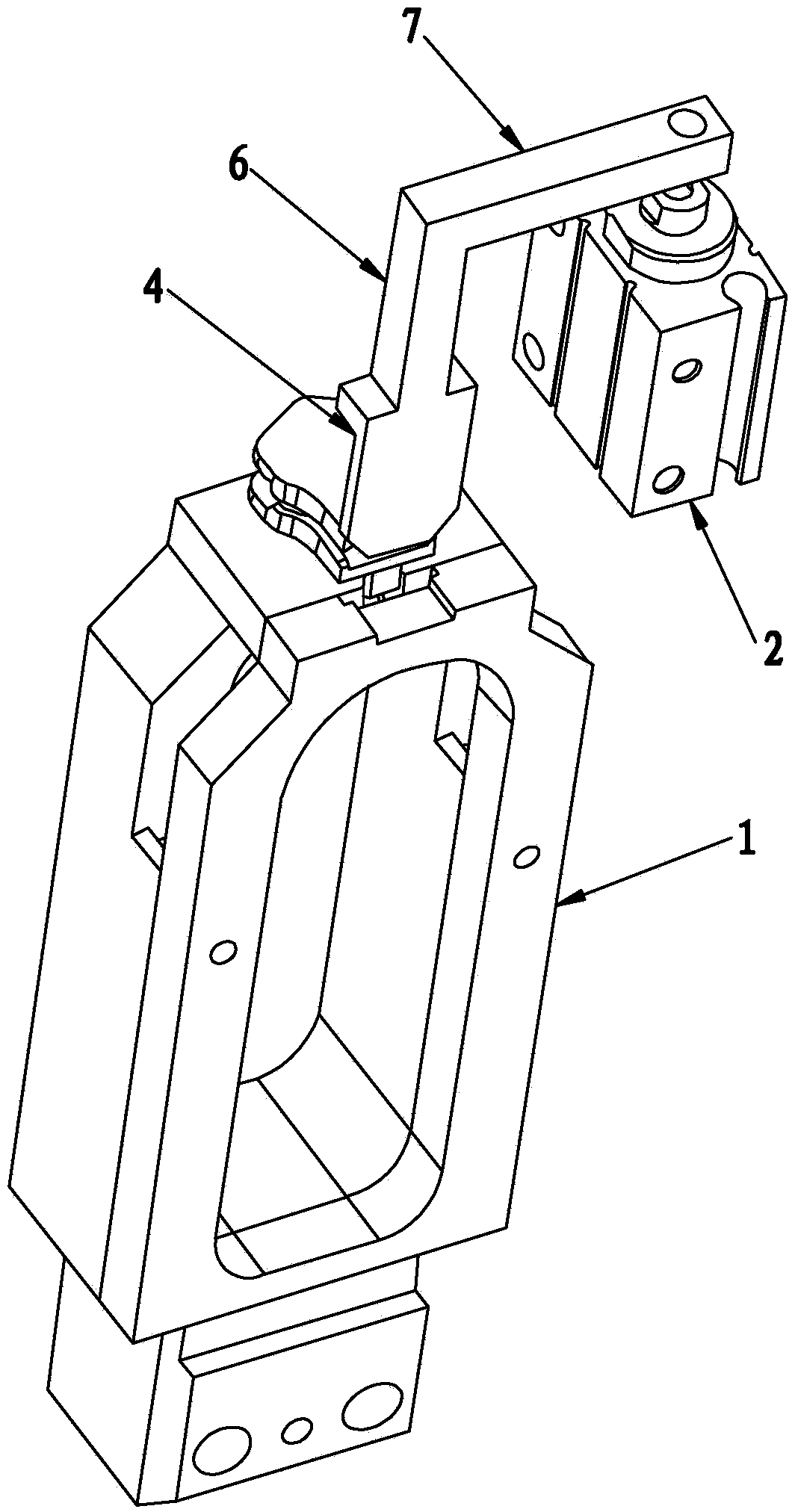

[0016] like figure 1 — Figure 4 The upper slider belt distributing device of a zipper machine shown includes a zipper puller safety installation frame 1, and the safety installation frame 1 is provided with an installation platform 11 for placing the zipper puller and a placement space 12 for the zipper to pass through , the safety mounting frame 1 is mounted with a sub-tape head 3 that can slide back and forth toward the placement space 12 and driven by the drive mechanism 2, and a sub-tape pressing shovel 4 that moves synchronously with the sub-tape head 3 . In the above scheme, the processed zipper is driven by the traction mechanism, so that it passes through the safety installation frame 1 of the zipper head. to the zipper; after the sub-tape head 3 is driven by the drive mechanism 2, it can move towards the placement space 12, and can separate the two fitable zippers that need to be placed on the zipper head at the placement space 12; the sub-band pressing shovel 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com